Method of loading superstructure integrated precast cabin unit

A prefabricated cabin, integrated technology, applied in ship construction, ship parts, ships, etc., can solve the problems affecting the installation efficiency of the whole prefabricated cabin unit of the Shanghai Construction, the difficulty of running the whole prefabricated cabin unit of the Shanghai Construction, and increase the consumption of engineering resources. The effect of improving hoisting transfer speed, reducing cost consumption, improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

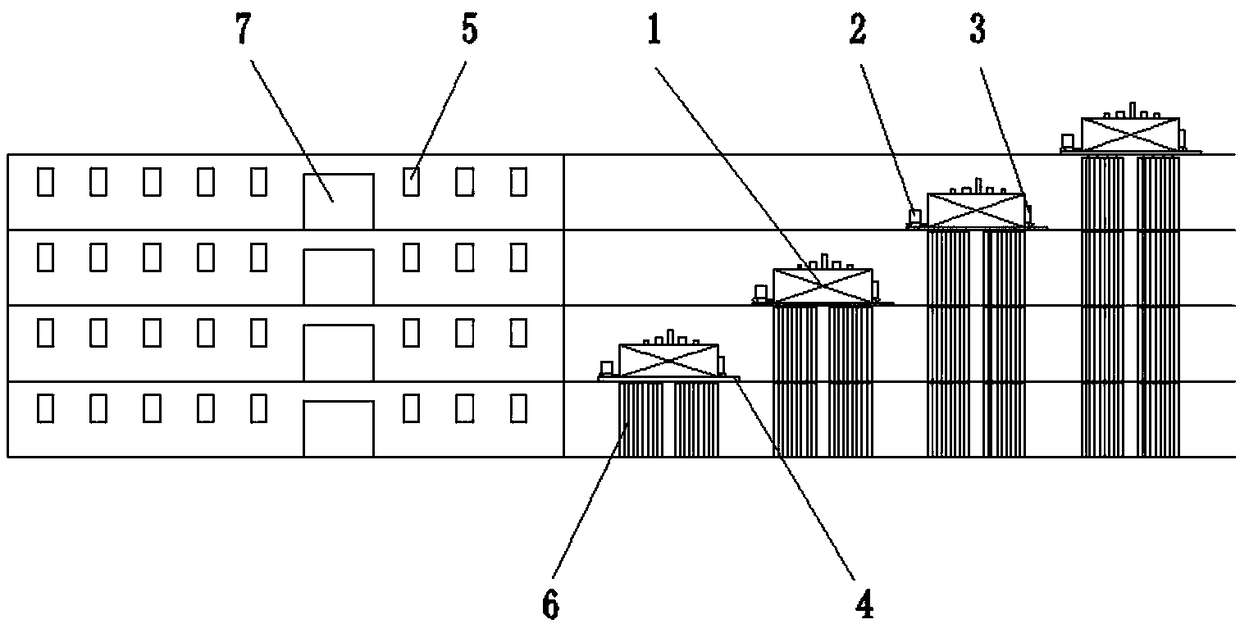

[0031] according to Figure 1-5 Shown, the present invention proposes a kind of technical scheme:

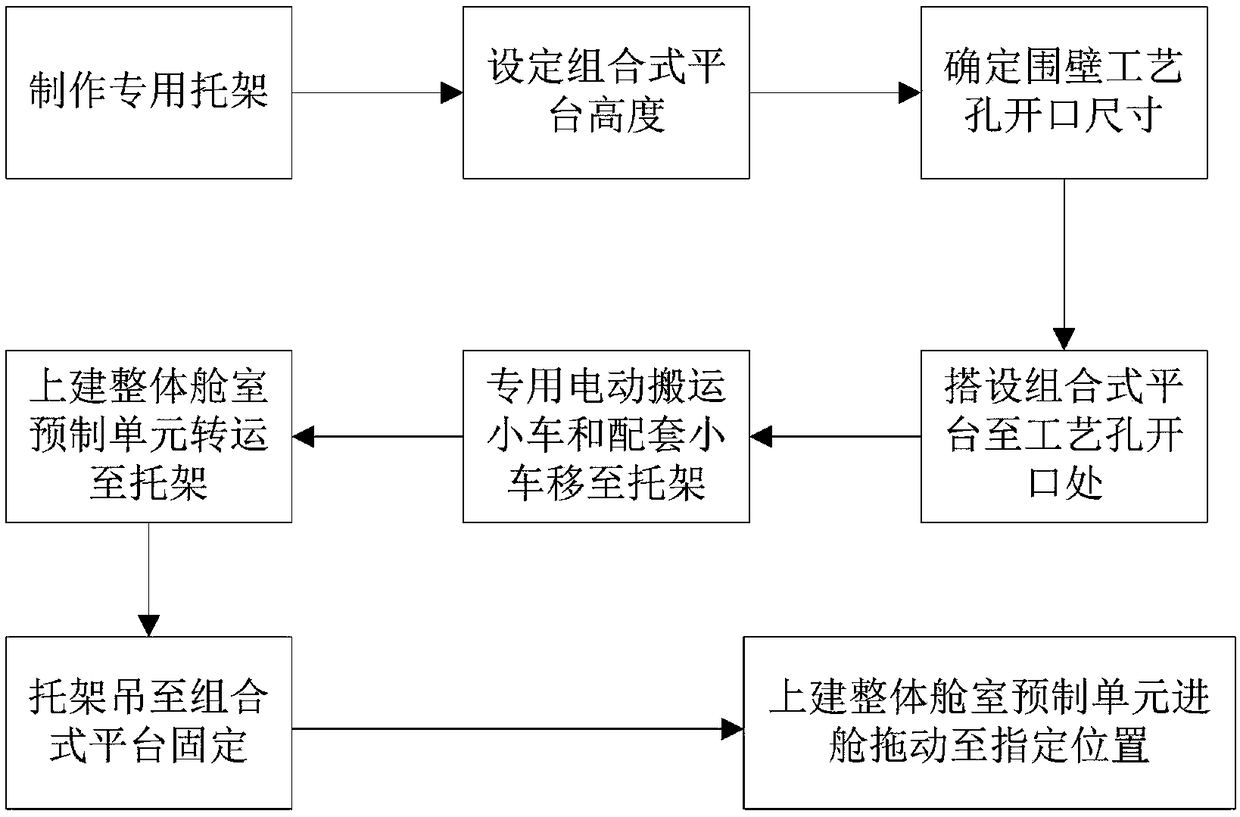

[0032] A method for entering the upper-built integral prefabricated cabin unit, comprising the following steps:

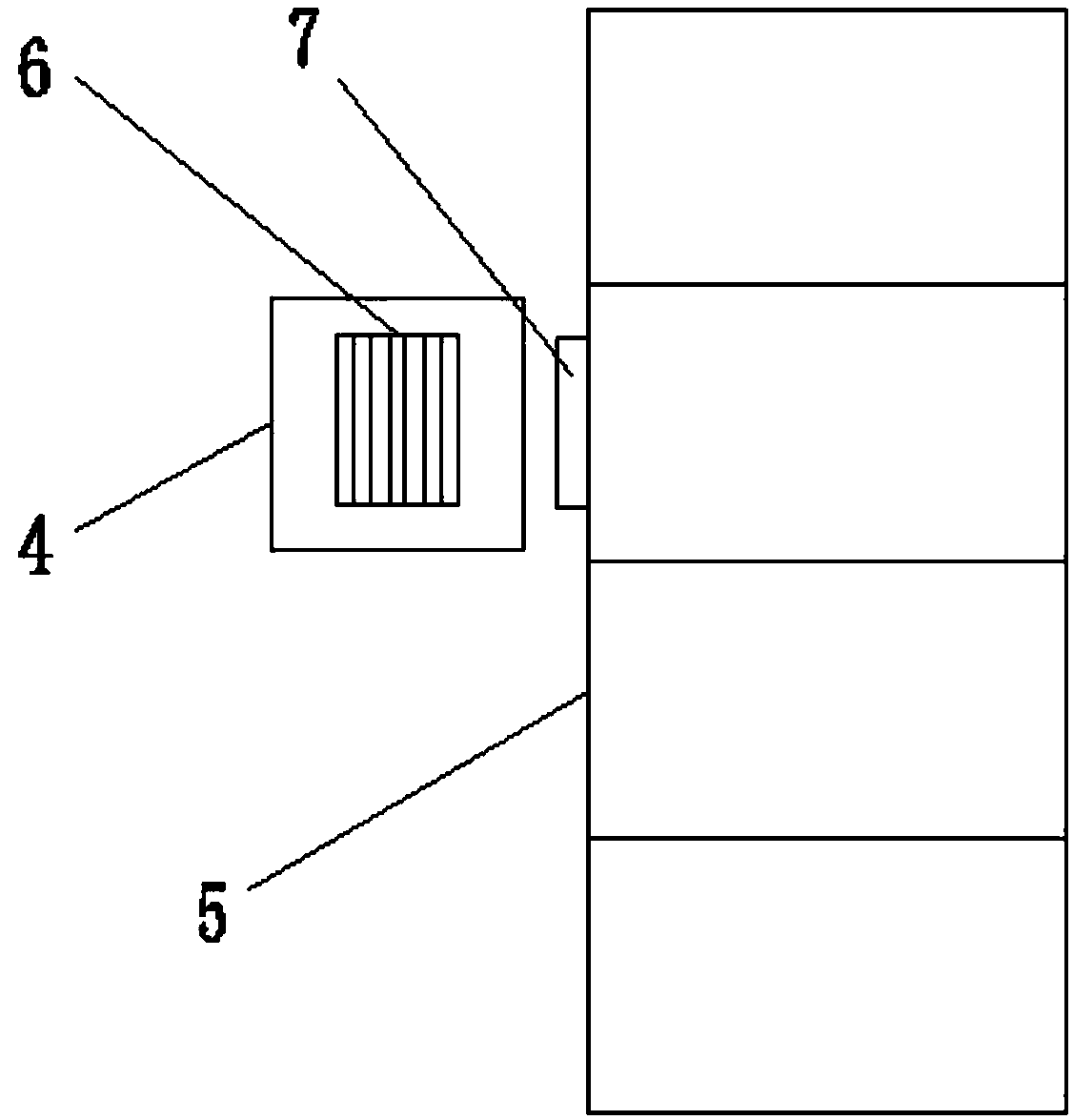

[0033] Step 1: According to the dimensional parameters of the overall prefabricated cabin unit 1, the dimensional parameters of the electric transport trolley 2 and the dimensional parameters of the supporting trolley 3, make the special bracket 4 according to the parameter standard, and the plane size of the special bracket 4 is the same as that of the electric transport trolley 2 and the superstructure The prefabricated cabin unit 1 and the supporting trolley 3 are compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com