Efficient balance system for lifting ship and working method of system

A balancing system and ship technology, applied in ship safety, using auxiliary nozzles or propellers to reduce ship movement, ships, etc., can solve problems such as tilting and overturning, cargo scattering, and inability to quickly adjust the ship's center of gravity to avoid rollover , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

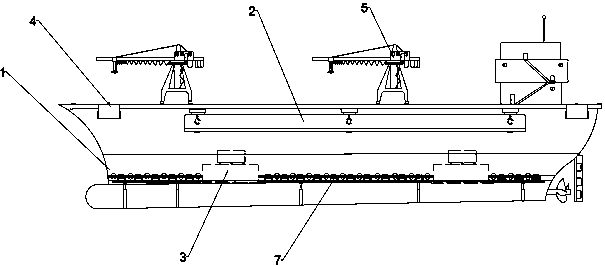

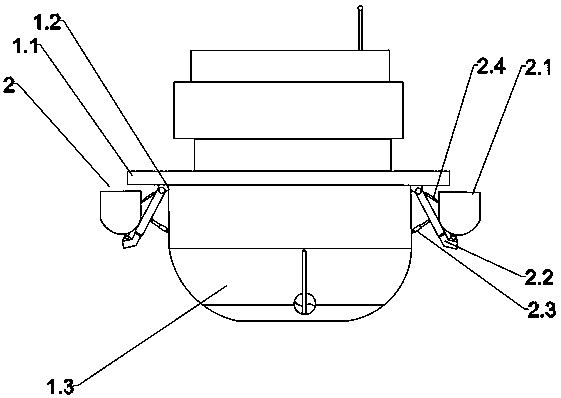

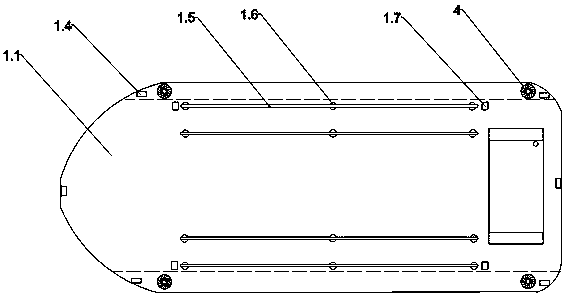

[0036]An efficient balancing system for a lifting ship, comprising a hull 1, characterized in that it also includes a balancing water tank 2, a tuning and balancing water tank 3, a lift fan 4, a self-balancing crane 5 and a PLC control system 6; the balancing water tank 2 is provided with The two groups are respectively arranged on the sides 1.2 of the hull 1. The balance tank 2 includes a tank body 2.1 and a hydraulic telescopic arm 2.2. The tank body 2.1 is a U-shaped boat structure with an open top, and the tank body 2.1 has a bottom Hinged to the extended end of the hydraulic telescopic arm 2.2, the side of the tank body 2.1 is hinged to the extended end of the flip hydraulic cylinder 2.4, the bottom end of the flip hydraulic cylinder 2.4 is hinged to the hydraulic telescopic arm 2.2, and the head of the hydraulic telescopic arm 2.2 The end is hinged on the ship's side 1.2, and the hydraulic telescopic arm 2.2 is provided with an extension hydraulic cylinder 2.3. 1.2 above...

Embodiment 2

[0043] The structure and principle of this embodiment 2 are basically the same as that of embodiment 1. The difference is that the rotary table 5.6 is provided with a crane rotation angle sensor 5.11. The PLC control system is convenient for the control system to quickly calculate the position of the center of gravity and adjust the balance of the hull.

Embodiment 3

[0045] The structure and principle of this embodiment 3 are basically the same as that of embodiment 1. The difference is that the balance arm 5.3 is provided with a fixed counterweight 5.7, and the counterweight can be used to balance the counterweight when the crane is empty, so as to avoid the crane being empty. Rollover occurs due to the shaking of the hull during loading, and the balance of gravity can also be used when lifting cargo.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com