Installing method of wall-mounted washing machine

An installation method and washing machine technology, which can be applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of deformation of the connection structure between bolts and positioning holes, separation of drum washing machines and walls, etc., and achieve the effect of improving the seismic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

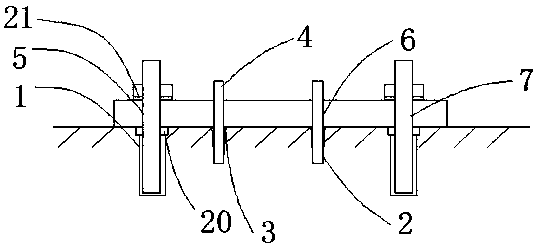

[0028] Such as figure 1 , figure 2 As shown, the installation method of a wall-mounted washing machine provided by the present invention includes:

[0029] a. Drill four first positioning holes 1 on the wall;

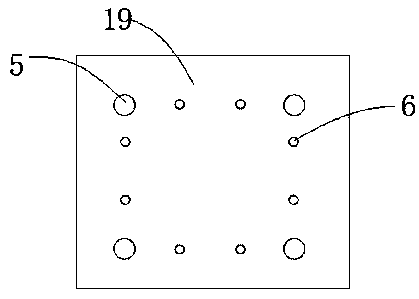

[0030] b. Drill a plurality of first through holes 5 corresponding to the positions of the first positioning holes on the mounting plate 19; drill a plurality of second through holes 6 corresponding to the positions of the second positioning holes 2 on the mounting plate;

[0031] c. install the screw mandrel 7 in the first through hole of the mounting plate through the nut 20, and directly insert the mounting plate with the screw mandrel into the first positioning hole;

[0032] d. After inserting the mounting plate with the first fastener into the first positioning hole, mark the position of the second positioning hole; then remove the mounting plate, drill holes on the wall with a Ф8 drill bit and drill multiple second positioning holes positioning hole; and ins...

Embodiment 2

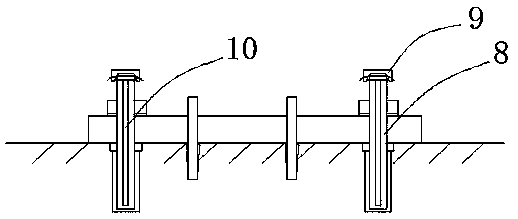

[0039] A method for installing a wall-mounted washing machine provided by the present invention includes: .

[0040] a. Drill four first positioning holes on the wall;

[0041] b. Drilling a plurality of first through holes 5 corresponding to the positions of the first positioning holes on the mounting plate; drilling a plurality of second through holes corresponding to the positions of the second positioning holes on the mounting plate;

[0042] c. Install the screw rod in the first through hole of the mounting plate through the nut, and directly insert the mounting plate with the screw rod into the first positioning hole;

[0043] d. After inserting the mounting plate with the first fastener into the first positioning hole, mark the position of the second positioning hole; then remove the mounting plate, drill holes on the wall with a Ф8 drill bit and drill multiple second positioning holes positioning hole; and insert expansion nails into the second positioning hole;

[...

Embodiment 3

[0049] A method for installing a wall-mounted washing machine provided by the present invention includes:

[0050] a. Drill four first positioning holes on the wall;

[0051] b. Inject adhesive into the first positioning hole;

[0052] c. Drive a first fastener into the first positioning hole where the adhesive is injected; the end of the first fastener away from the wall is used to fix the wall-mounted washing machine;

[0053] d. Align the installation holes of the wall-mounted washing machine with the first fasteners one by one and assemble them together and fix them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com