Stationary waste cleaner

一种清污机、固定式的技术,应用在移土机/挖土机、水利工程、人工水道等方向,能够解决清污机无法完全保证污物输送至水流外部、清污范围有限、实用性降低等问题,达到增加清污范围、方便处理、提高实用性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

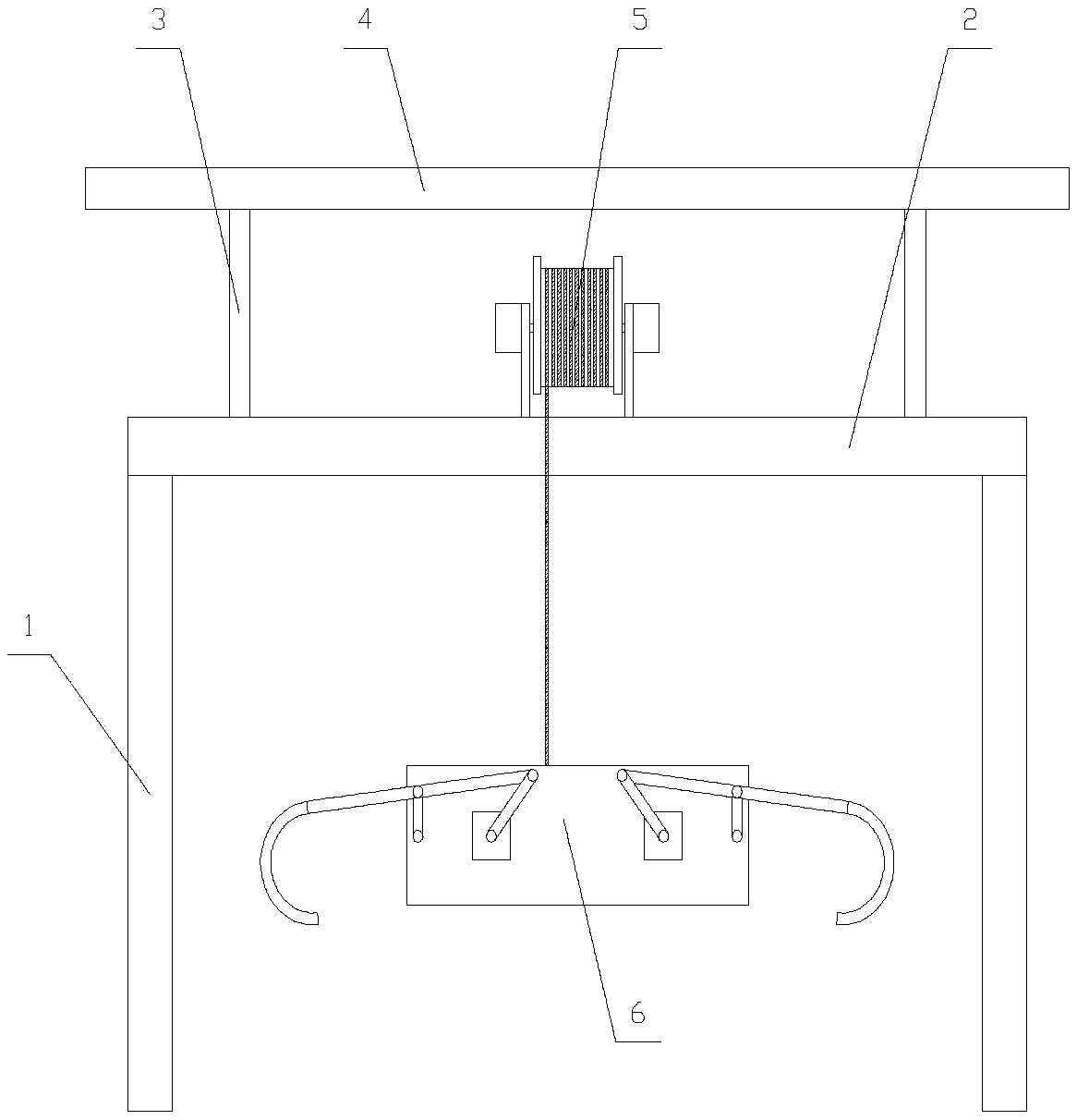

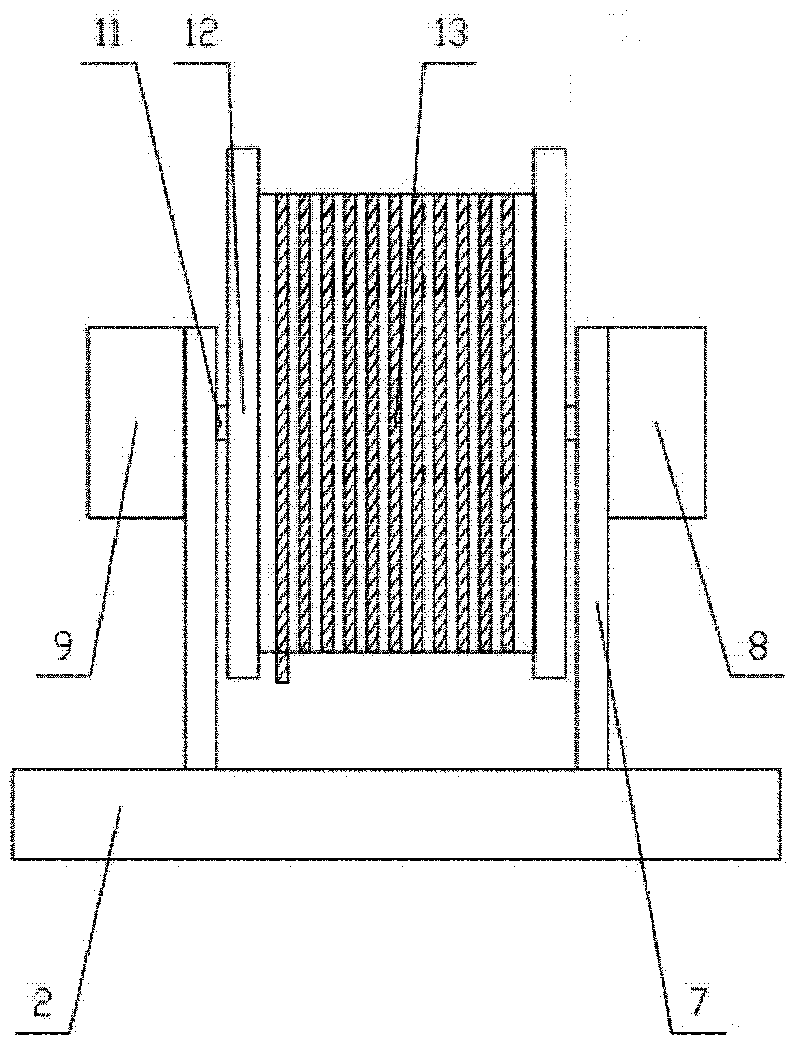

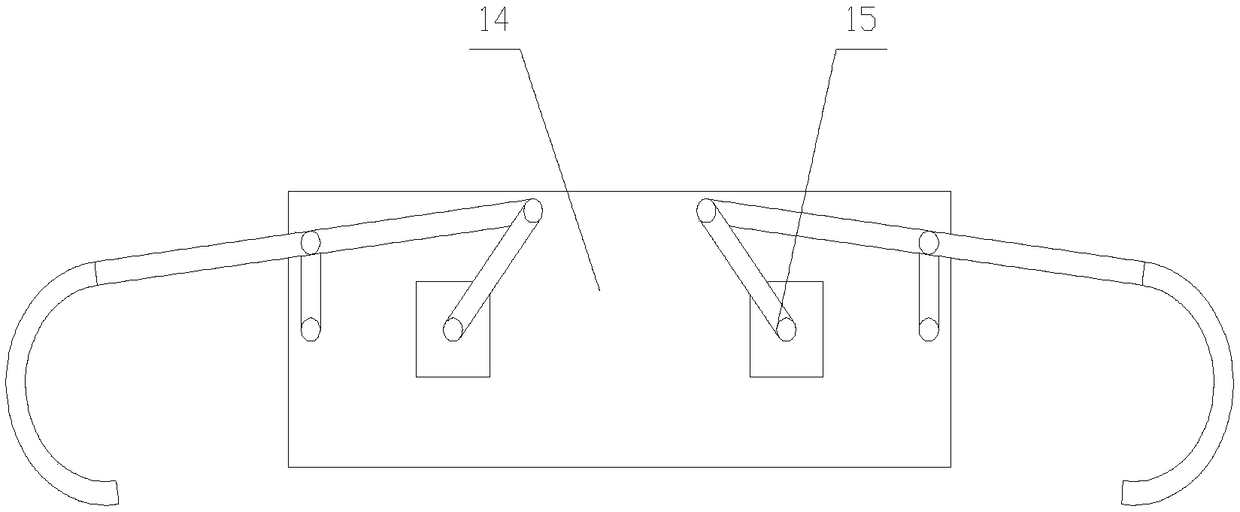

[0031] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0032] Such as Figure 1-Figure 6 As shown, an intelligent fixed cleaning machine applied to hydroelectric power generation projects includes a crossbar 2, a lifting mechanism 5, a cleaning mechanism 6 and two pillars 1, and the crossbar 2 is erected on the top of the pillar 1. The cleaning mechanism 6 is arranged between the two pillars 1, and the lifting mechanism 5 is arranged above the cross bar 2 and connected with the cleaning mechanism 6 in transmission;

[0033] The decontamination mechanism 6 comprises a decontamination box 14 and two extension units 15, the decontamination box 14 comprises a top plate 21, a first side plate 22, a second side plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com