Multifunctional shoot nail assembly

A multi-functional, nail-shooting technology, applied in the field of nail-shooting, can solve problems such as high noise during nail-shooting, inability to meet the needs of security doors, plastic-steel doors and windows, discomfort, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

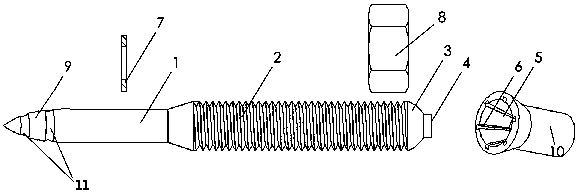

[0014] like figure 1 As shown, the multi-functional nail shooting assembly includes a nail rod 1, the head end of the nail rod 1 forms a nail point 9, and the tail end has a spherical protrusion 3, and a cylinder 4 is extended upwards from the top of the spherical protrusion 3. External threads 2 are provided from the middle part to the tail end. The launch shell 10 is a cylindrical shell with a transverse separator (not shown in the figure) in the middle. The inner diameter of the end of the cylindrical shell on the side of the separator gradually becomes larger, forming a bell mouth, and the inside of the bell mouth is a spherical concave. The mouth 5, the inner wall of the spherical notch 5 is evenly provided with several grooves 6 upward along the inner wall, such as 3, 6 and so on. The length and the inner diameter of the cylindrical shell from the top of the spheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com