Gas tube joint of gas cooker

A gas pipe joint, gas stove technology, applied in the direction of pipe/pipe joint/pipe fitting, hose connection device, gas/liquid distribution and storage, etc. The effect of swinging and avoiding gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail by specific embodiment now in conjunction with accompanying drawing:

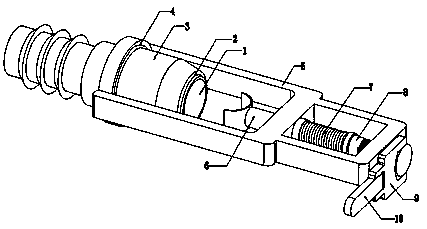

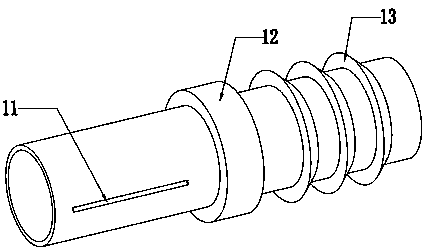

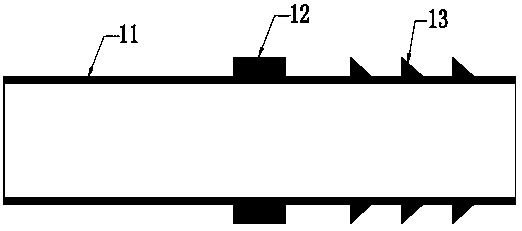

[0031] like Figure 1 to Figure 12 As shown, a gas stove gas pipe joint, the gas stove gas pipe joint includes a gas pipe 1, a front sealing ring 2, a sealing joint 3, a middle sealing ring 4, a push rod support frame 5, a push rod 6, a spring 7, a rotating rod 8. Connecting rod 9, handle 10; the trachea 1 is cylindrical as a whole; the front sealing ring 2 is set on the front inner side of the sealing joint 3; the middle sealing ring 4 is set at the limit position of the middle sealing joint of the sealing joint 3 block place; the ejector rod support frame 5 is connected on the sealing joint 3 with a rotating shaft; the ejector rod 6 is installed in the ejector rod support frame 5; the spring 7 is installed on the ejector rod 6 and Between the rotating rods 8; the connecting rod 9 is connected to the tail end of the rotating rod 8; the handle 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com