A large-angle attitude angle measurement device and method for a three-axis air bearing platform

A technology of measuring device and air-floating platform, which is applied in the directions of measuring device, measuring angle, surveying and mapping and navigation, etc., can solve the problems of measuring accuracy not meeting the requirements of technical indicators, gyroscope occupying a large space of instrument platform, increasing project cost, etc. High-precision angular position control, fast tracking, and reduced complexity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

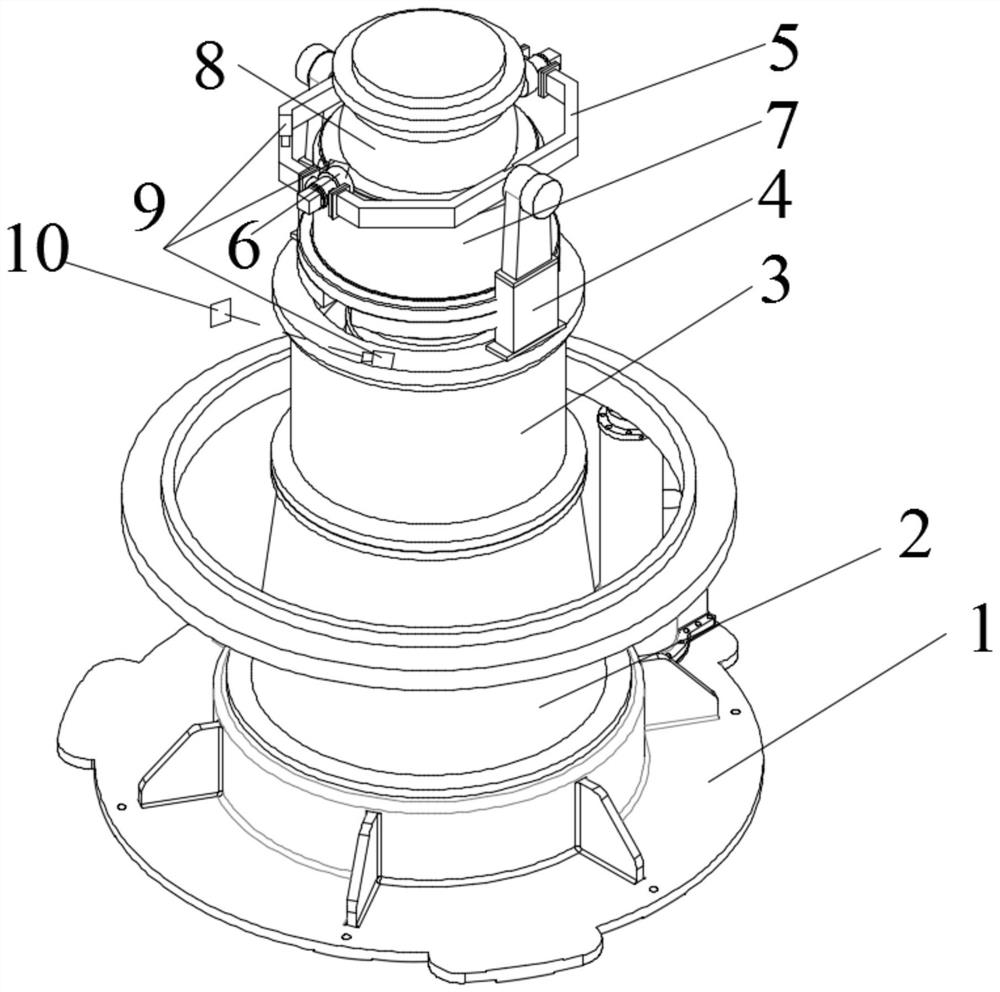

[0052] The outer ring part 3 of the three-axis mechanical electric tracking turntable in the large-angle attitude angle measuring device of the three-axis air bearing platform adopts an outer rotor motor, which can reduce the complexity of the mechanical structure. The structure of the three-axis air flotation table is the base 1 of the three-axis air flotation table whose bottom end is pressed on the adjustment pad iron. , used to connect the base 1 of the three-axis air bearing table and the large-angle attitude angle measuring device of the three-axis air-floating table, the large-angle attitude angle measuring device is installed on the column 2 of the three-axis air bearing table, and the three-axis machine of the large-angle attitude angle measuring device The static part of the outer ring shaft of the electric tracking turntable, the motor stator and the fixed shaft of the outer ring are installed on the column 2 of the three-axis air flotation table, and the 7 parts of ...

Embodiment 2

[0054] The three-axis mechanical and electric tracking turntable can not only be used for the large-angle attitude angle measurement of the three-axis air bearing platform by installing the eddy current displacement sensor 9, but also can use the device of the present invention to install a four-face on the inner ring part 6 of the three-axis mechanical and electric tracking turntable. Body prism, two orthogonal photoelectric autocollimators are installed on the instrument platform of the air bearing platform to replace the eddy current displacement sensor 9 and the metal block 10 structural scheme to measure the large-angle attitude angle of the three-axis air bearing platform.

Embodiment 3

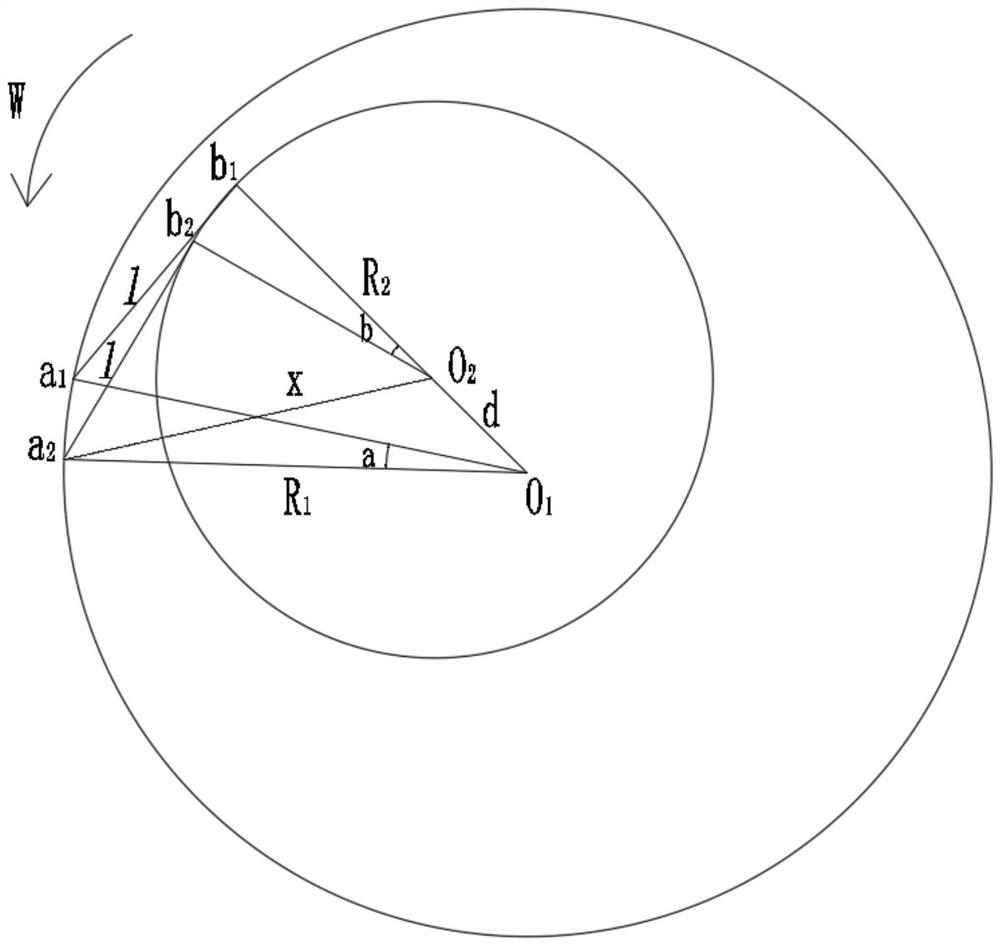

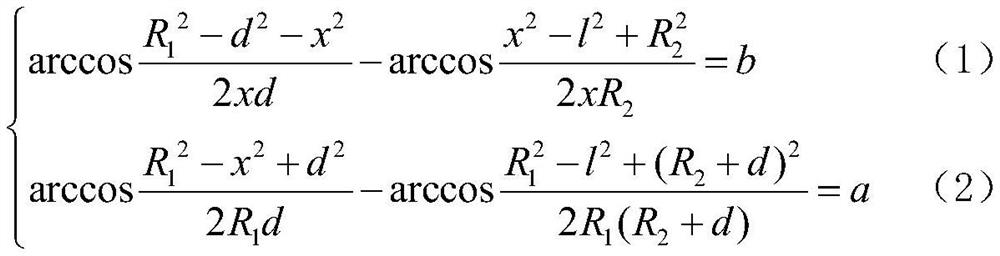

[0056] When the rotation center of the three-axis air bearing table does not coincide with the rotation center of the three-axis mechanical electric tracking turntable, it is assumed that the three-axis air bearing table rotation center, the three-axis mechanical electric tracking turntable rotation center, and the installation position of the eddy current displacement sensor are on a straight line , the motion angle a of the three-axis air bearing table, the motion angle b of the three-axis mechanical electric tracking turntable and the installation position R of the eddy current displacement sensor are deduced 2 , metal block installation position R 1 , The relationship between the measured value l of the eddy current displacement sensor and the misalignment error d of the center of rotation:

[0057]

[0058] Use Matlab to find the numerical relationship between the attitude angle measurement error of the three-axis air bearing platform and other parameters:

[0059] (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com