A Concrete Impermeability Instrument Using Magnetic Force Conversion to Negative Pressure Adhesion

A technology of concrete and anti-seepage meter, which is applied in the field of concrete anti-seepage meter, which can solve the problems of low test efficiency, imperfect technical considerations, inconvenience, etc., and achieve the effect of speeding up test efficiency, improving accuracy and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

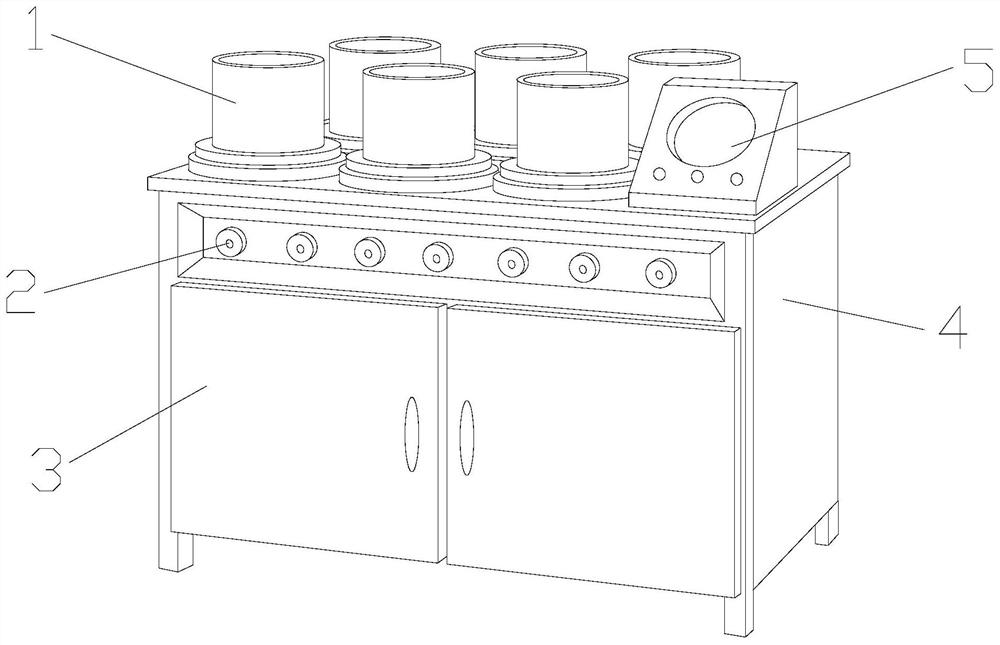

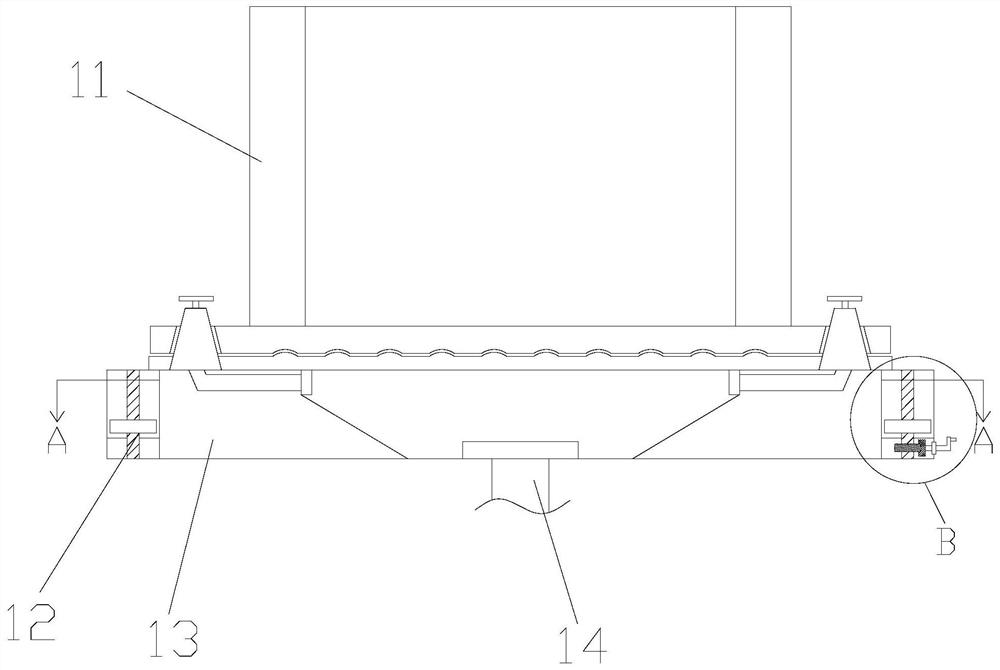

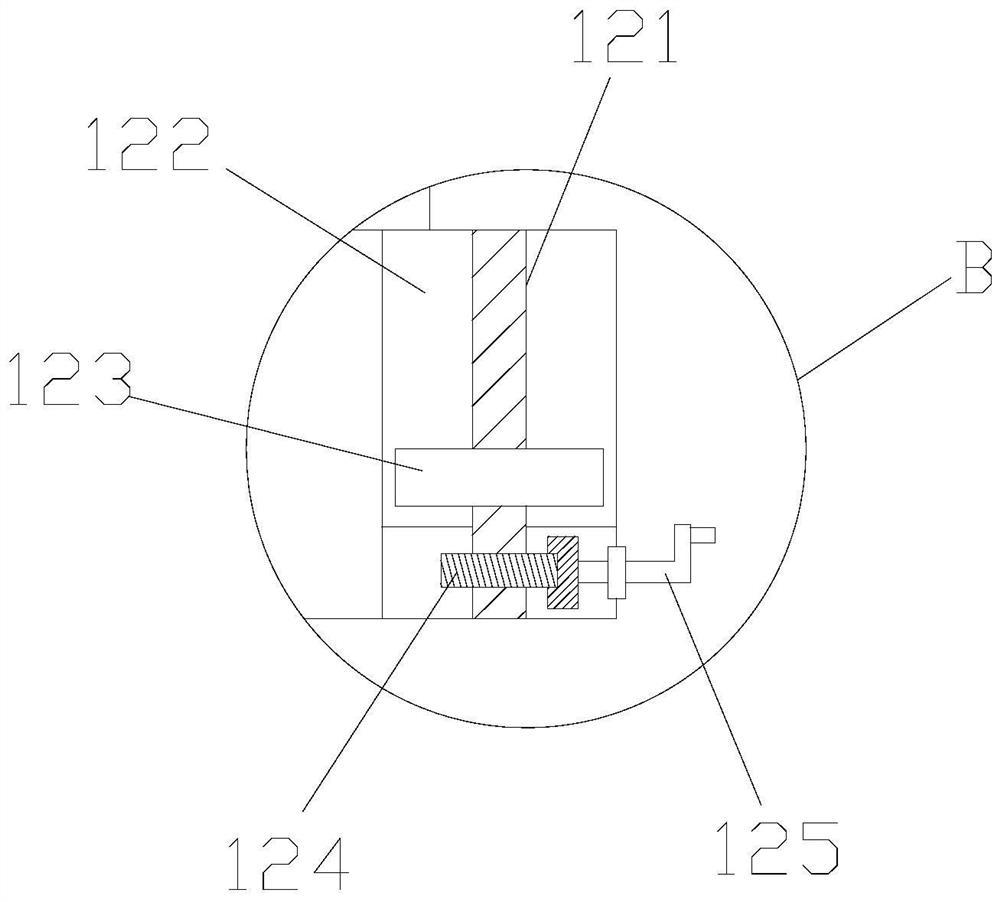

[0023] see Figure 1-Figure 2 , the present invention provides a concrete anti-seepage instrument that adopts magnetic force conversion to negative pressure suction, and its structure includes a concrete fixed monitoring platform 1, a pressure regulating valve 2, an inspection door 3, an anti-seepage instrument workbench 4, and a controller 5. The workbench 4 of the anti-seepage meter has a rectangular structure and is placed horizontally on the ground. The inspection door 3 is bolted to the left and right ends of the front of the workbench 4 of the anti-seepage meter. Above the front inspection door 3 of the workbench 4, the concrete fixed monitoring platform 1 is mechanically connected to the upper surface of the workbench 4 of the anti-seepage meter, and the controller 5 is located at the lower right corner of the upper surface of the workbench 4 of the anti-seepage meter. The monitoring platform 1 is composed of a concrete sealed mold cavity 11, a magnetic transmission str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com