Non-polarized low-voltage circuit breaker

A low-voltage circuit breaker, non-polarity technology, which is applied in the direction of circuit breaker components, circuit breaker contacts, protective switch operation/release mechanism, etc., can solve the problems of inability to achieve reliable arc ignition and arc extinguishing effects, and achieve favorable arc The effect of extinguishing and short breaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

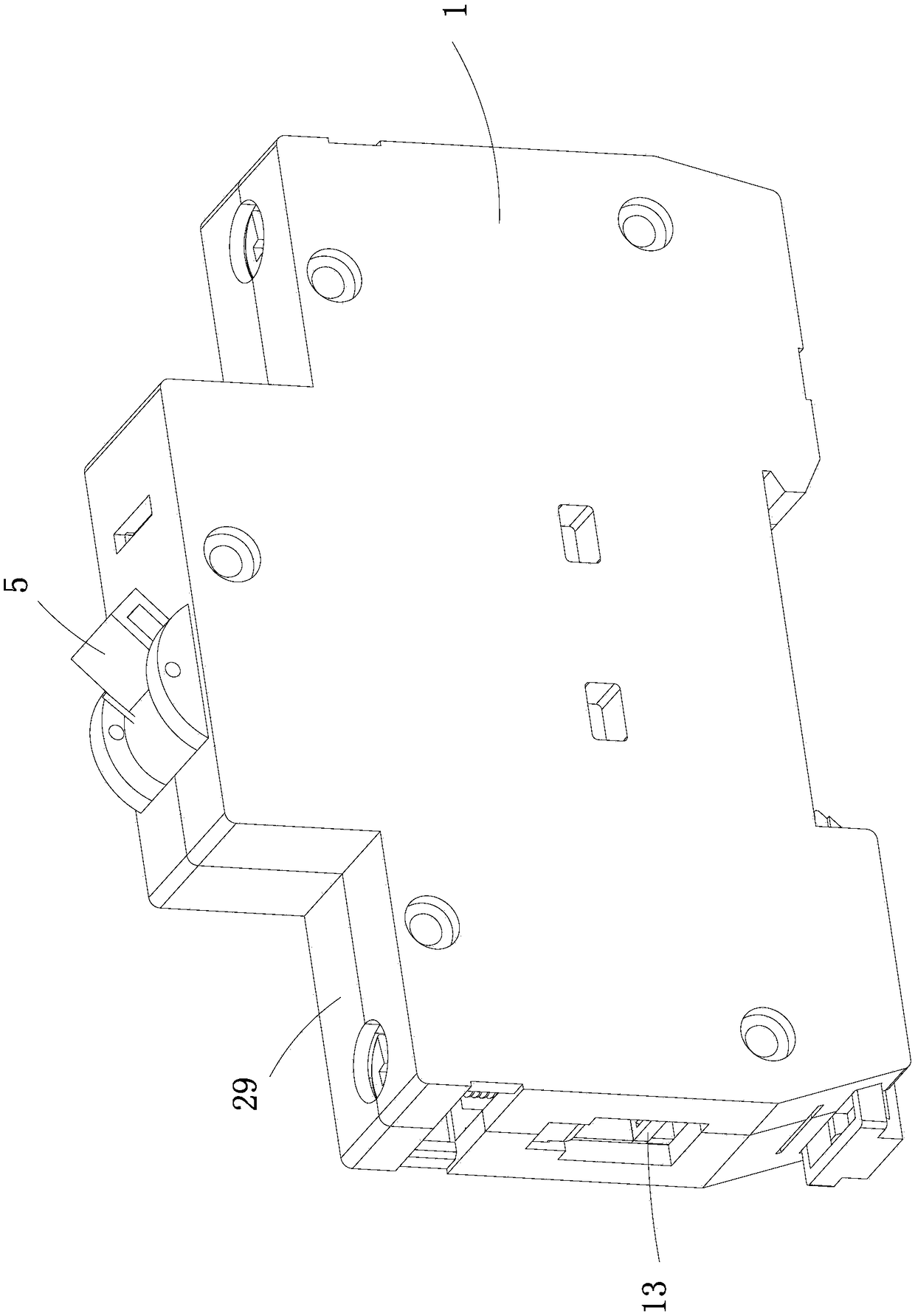

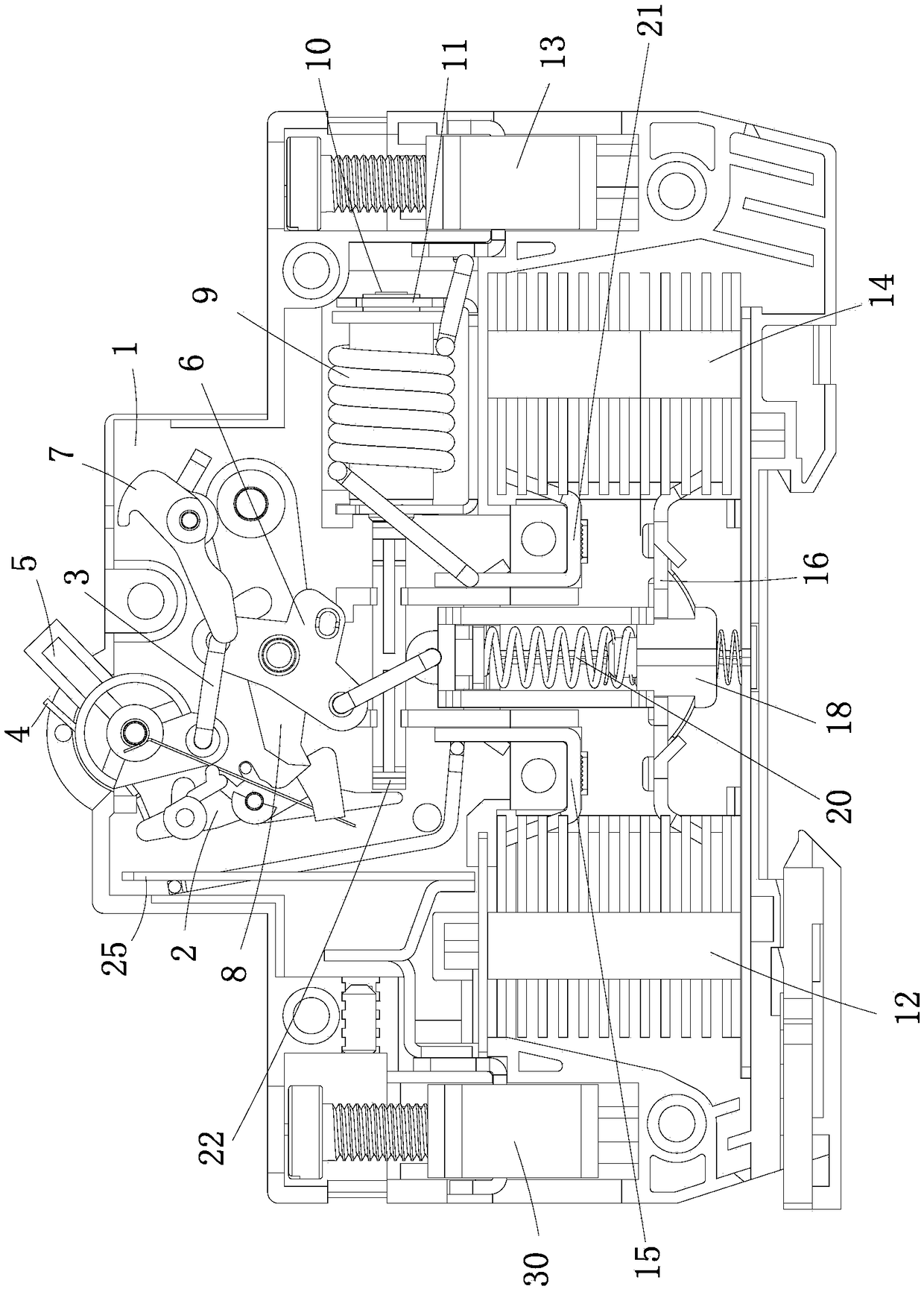

[0033] Example 1: Such as Figure 1 to Figure 6 As shown, the non-polar low-voltage circuit breaker provided by the present invention mainly includes: a plastic shell and left and right wiring clamp components placed therein, an operating mechanism, a magnetic trip system, a thermal trip system, a bridge type movable contact assembly 16, two groups Static contact assembly and two arc extinguishing chambers. The housing includes a base 1 and an upper cover 29, and all internal parts of the circuit breaker are installed based on the base 1 and the upper cover 29. Among them, the left wiring clamp assembly 30 is connected to the thermal trip system and the power supply, the right wiring clamp assembly 13 is connected to the magnetic trip system and the load, and the magnetic trip system and the thermal trip system pass through the bridge movable contact assembly 16 and the static contact assembly The closing of 15 realizes electrical connection. The bridge-type moving contact as...

Embodiment 2

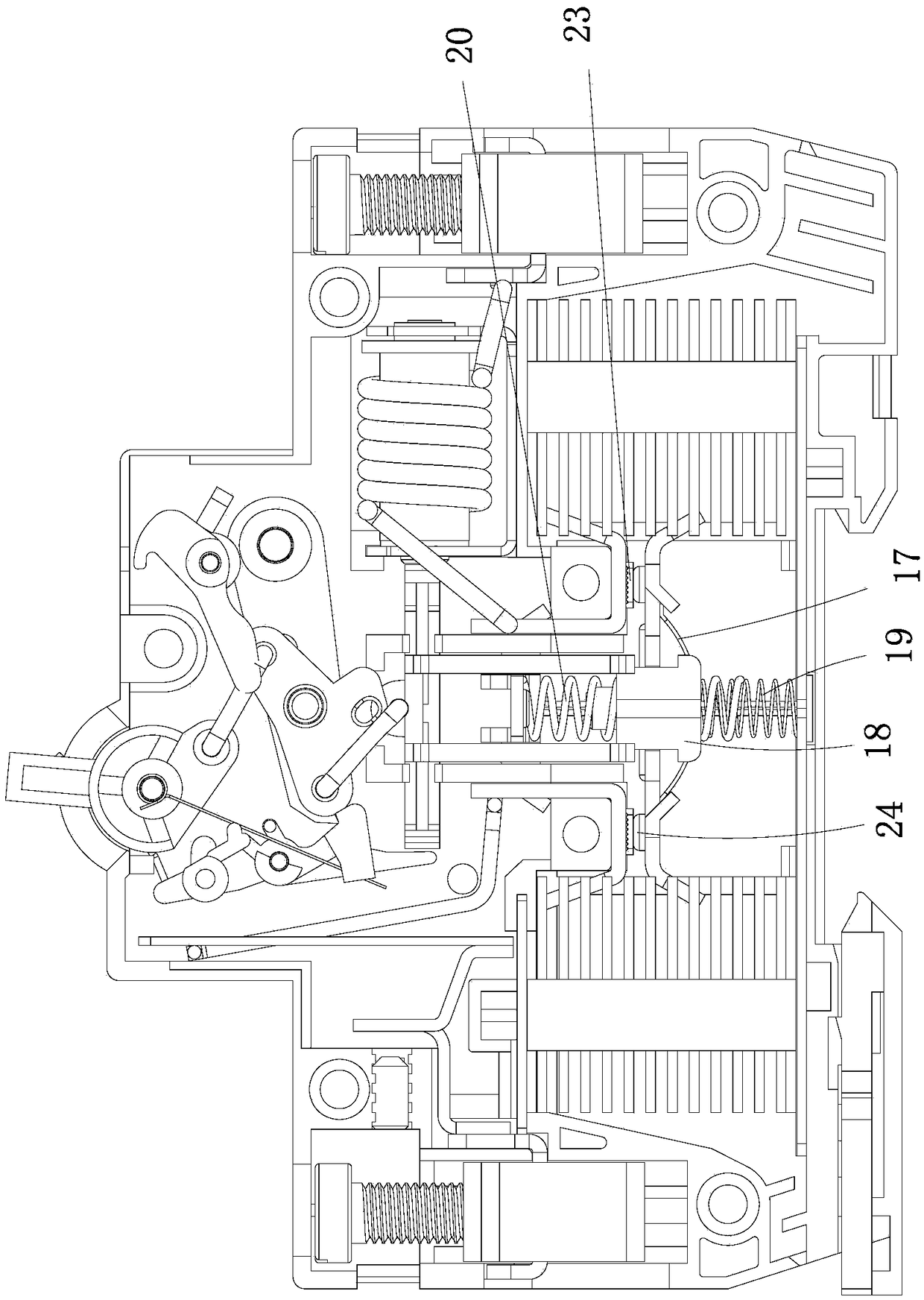

[0047] Embodiment 2: The difference between this embodiment 2 and embodiment 1 is that two springs 34 are used instead of the spring leaf 17 described in embodiment 1, such as Figure 7 with Picture 9 As shown, two springs 34 are located between the contact bridge and the moving contact bracket 18, and are respectively located below the two moving contacts. The bridge type moving contact assembly 16, the two springs 34 and the moving contact bracket 18 constitute the contact. The overtravel mechanism has better stability. Move the moving contact bracket up and drive the bridge type moving contact assembly to contact with the left and right static contact assemblies, then continue to move the contact bracket up, the moving contact bracket compresses two springs, and the two springs are bridge type moving contacts The closure of the component and the static contact component provides reliable contact pressure. The upper end of the conductive spring 19 passes through the avoidanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com