Gas-producing arc extinguishing powder and preparation method thereof

An arc extinguishing and powder technology, which is applied in the manufacture of electrical components, fuses, circuits, etc., can solve problems such as difficulty in controlling the uniformity of filling density, fast heat dissipation, and great influence on the production area, so as to reduce the concentration of metal ions and the probability of collision, increase The effect of internal pressure and arc extinguishing ability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] And the preparation method of above-mentioned gas generation arc extinguishing powder can adopt following technical scheme:

[0042] Including the following steps,

[0043](1) Material weighing: Weigh various raw materials of the required quality according to the formula ratio for use;

[0044] (2) Addition of inorganic flame retardant in fumed silica powder: mix and granulate the fumed silica powder obtained in step 1) with the inorganic flame retardant powder of required mass ratio in a granulator, so that The inorganic flame retardant powder is evenly coated on the surface of the fumed silica powder;

[0045] (3) Addition of silicate: Mix and granulate the silicate powder with the required mass ratio and the coated powder obtained in step (2) in a granulator, so that the silicate powder is evenly coated on the powder body surface;

[0046] (4) Adding of organic flame retardant: Mix and granulate the organic flame retardant powder with the required mass ratio and t...

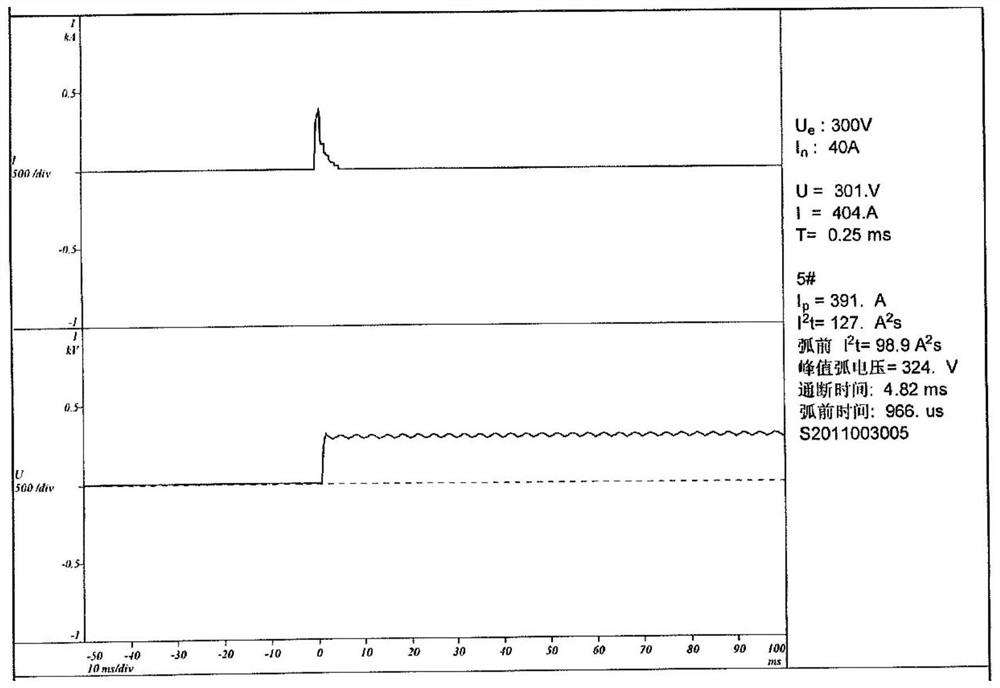

Embodiment 1

[0051] Weigh the mass ratio in a container as fumed silica powder: melamine modified urea-formaldehyde resin: magnesium silicate = 5wt%: 25wt%: 30wt% and add it to the container while stirring, then pour into granulation Granulate in the machine, sieve through a 100-200-mesh sieve, and place it in another clean container to obtain a semi-finished spherical powder 1. Then according to step (4) adding mass ratio is semi-finished spherical powder 1: Al (OH) 3 = 60wt%: 10wt% in the container containing the semi-finished spherical powder 1, fully stirred and mixed with a glass rod, poured into the granulator again for secondary granulation, and passed through a 100-200 mesh screen Powder 2 was obtained after sieving. Then resorcinol: formaldehyde: melamine: ethanol: acid in molar ratio 1:3:0.1:11:0.06 is mixed by magnetic force and placed in the oven to gel, evenly prepare melamine doped resorcinol-formaldehyde ( N-RF) sol, then grind it into powder with an agate mortar, screen o...

Embodiment 2

[0055] Weigh the mass ratio in a container as fumed silica: melamine modified urea-formaldehyde resin: magnesium silicate = 10wt%: 20wt%: 20wt% of the proportioning while stirring, join in the container, then pour into the granulator granulate in the container, sieve through a 100-200-mesh sieve, and place it in another clean container to obtain a semi-finished spherical powder 1. Then according to step (4) adding mass ratio is semi-finished spherical powder 1:Mg(OH) 2 =50wt%: 15wt% in the container containing the semi-finished spherical powder 1, fully stirred and mixed with a glass rod, poured into the granulator for secondary granulation, and passed through a 100-200 mesh screen After sieving, powder 2 was obtained, and then resorcinol: formaldehyde: melamine: ethanol: acid was mixed in a molar ratio of 1:4:0.08:10:0.07, stirred by magnetic force and placed in an oven to gel, and the melamine blend was evenly prepared. Miscellaneous resorcinol-formaldehyde (N-RF) sol is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com