Method and equipment for automatically refining noodles

An automatic refining and noodle technology, which is applied in the direction of dough forming machinery or equipment, dough mixer, dough fermenter, etc., can solve the problems of large gap between noodles, no resting, and increase the tendon of the noodles, so as to improve the tendon and save time. , the effect of increasing the wake-up speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

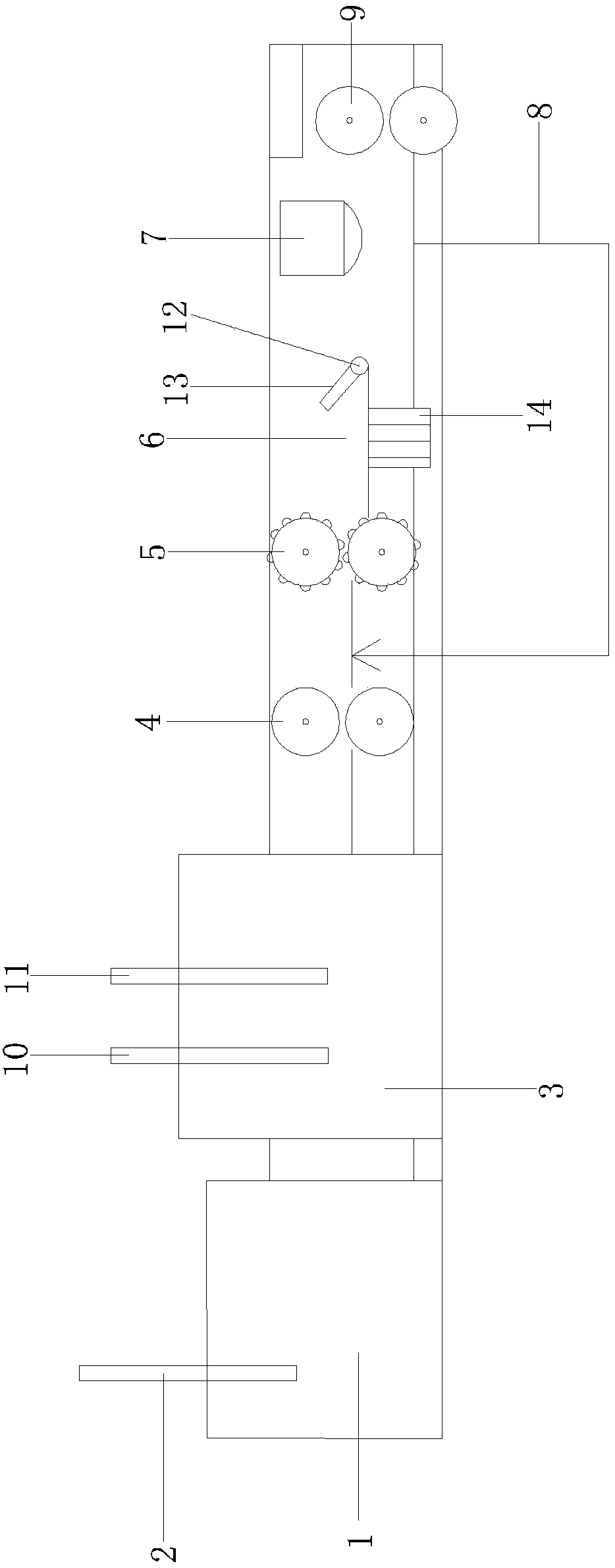

[0030] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment: see figure 1 .

[0031] The method for refining noodles automatically comprises the following steps:

[0032] g. Kneading dough: the fixed proportion of water and flour, the total number of water and flour added is 10 parts, input into the kneading bucket, and the water and flour are kneaded into dough by motor drive and dough rod rotation. During the mixing process, add 0.1 part of transglutaminase;

[0033] h. Refreshing: the dough is transported to the resting box, the temperature of the resting box is kept at 22-32 degrees, the humidity probe is inserted into the dough to detect the humidity, and the gluten structure observation lens is inserted into the dough to observe the gluten structure of the dough. When the internal gluten structure forms a network, the resting process ends;

[0034] i, rolling noodles: including the following steps:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com