Seat assembly

A seat assembly and fixing technology, which is applied to chairs, other seating furniture, stools, etc., can solve the problem of low assembly efficiency of seat assemblies, and achieve the effects of strong promotion significance, reduction of production costs, and convenient installation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

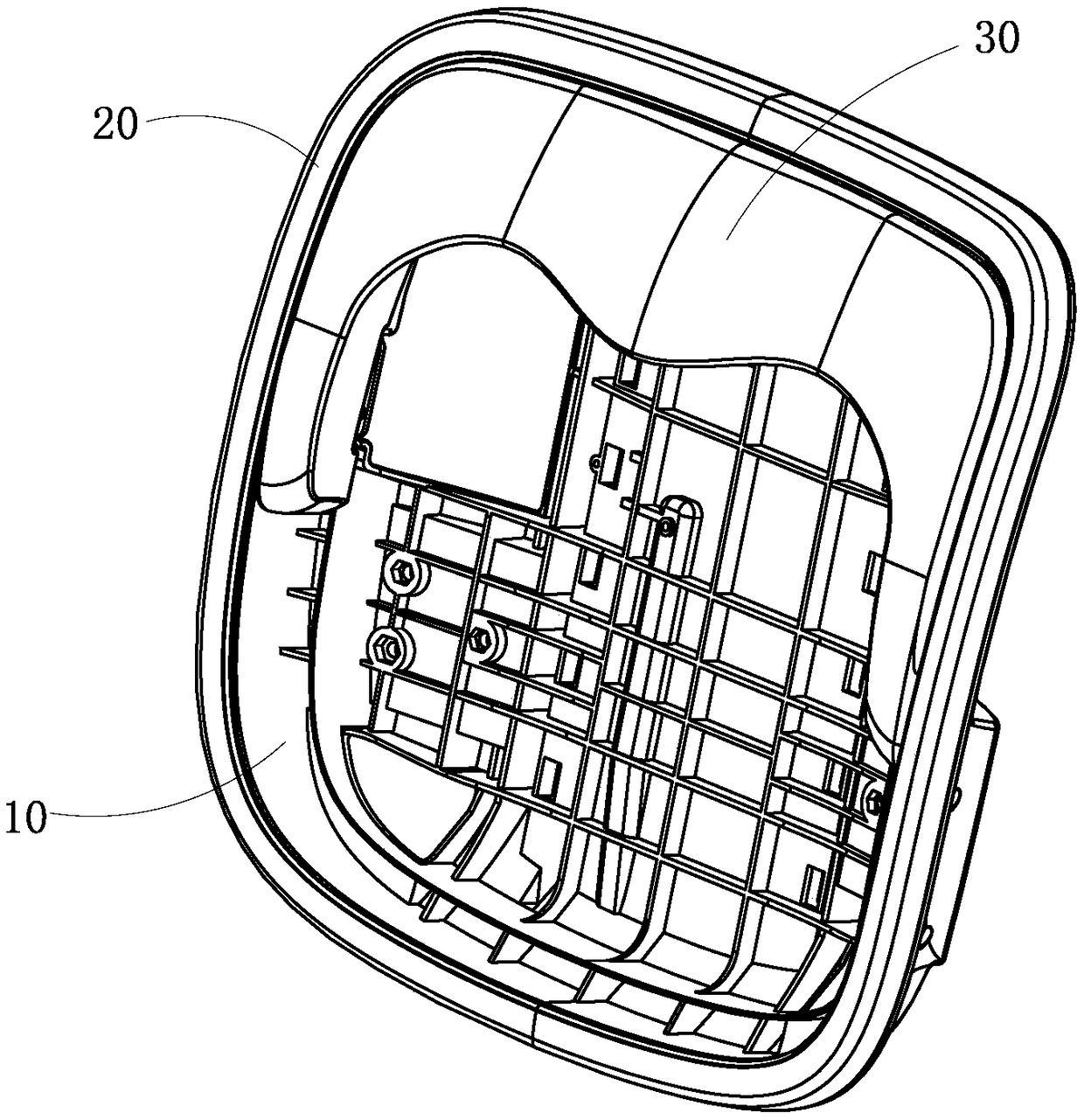

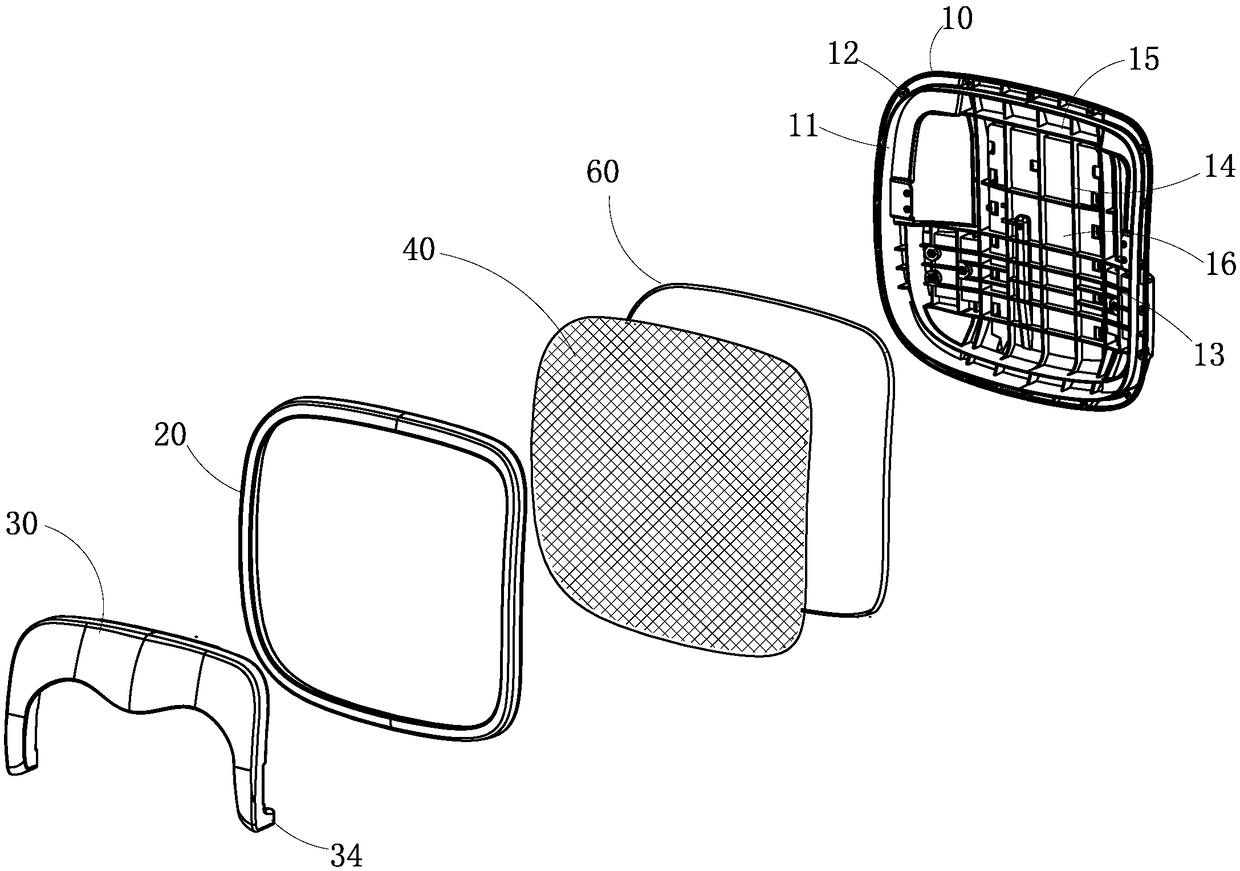

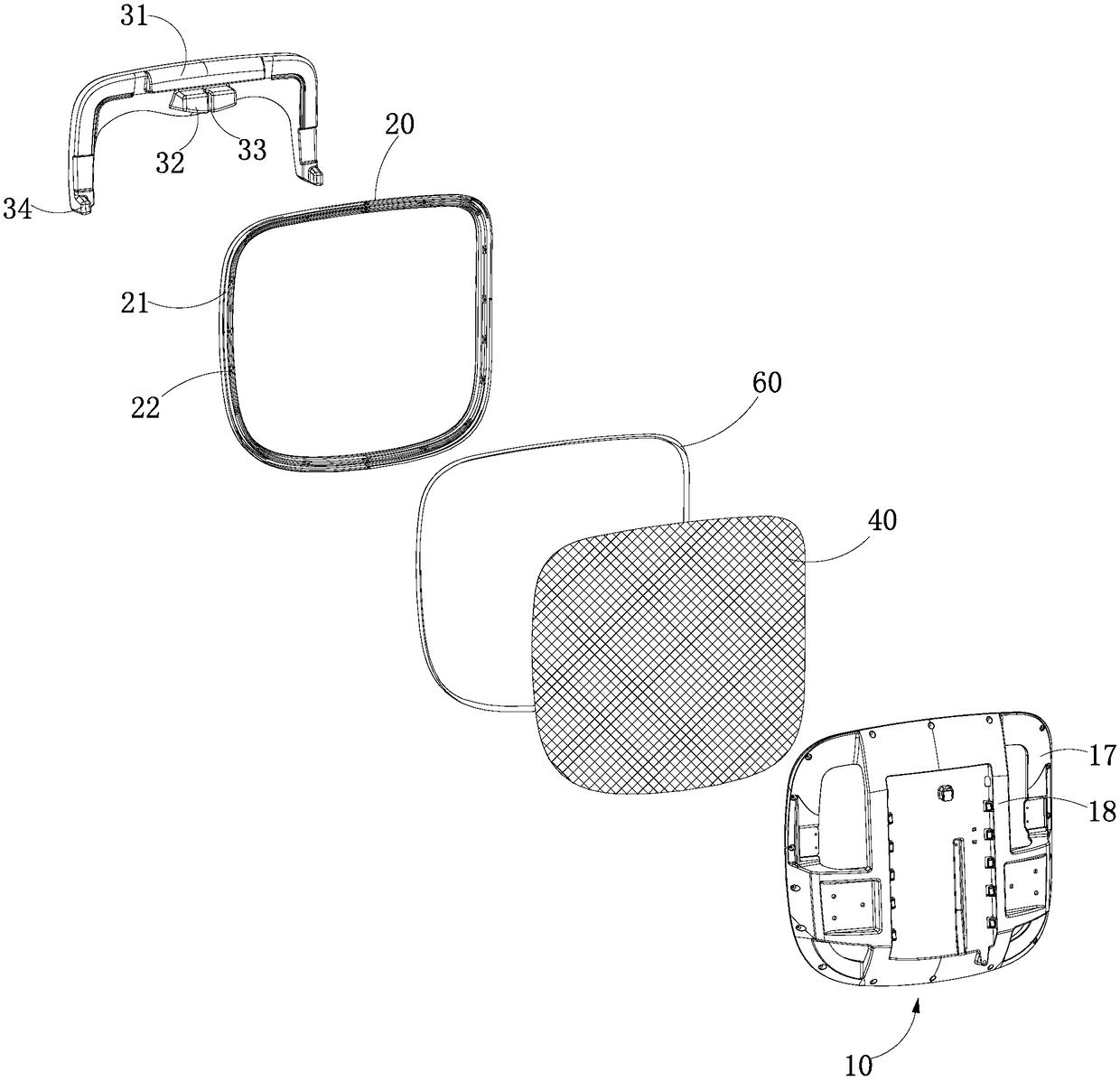

[0018] Such as Figure 1 to Figure 5 As shown, the present invention provides a seat assembly, the seat assembly can be a back frame or a seat basket, which includes an inner frame 20, an outer frame 10, foam 30, mesh cloth 40, several side strips 60 and several fixing parts 50 , the inner frame 20 and the outer frame 10 cooperate with each other, the edge part of the net part 40 is sandwiched between the inner frame 20 and the outer frame 10, and the fixing part 50 connects the inner frame 20, the outer frame 10 and the net part 40 are connected as a whole, and the foam 30 is fixed on the outer frame 10 .

[0019] The side strip 60 can be made of PVC or other materials, and the side strip 60 is divided into several sections (or adopts an integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com