Bathtub and manufacturing process of bathtub

A manufacturing process and technology for bathtubs, applied in bathtubs, showers, household appliances, etc., can solve problems such as inconvenience, damp build-up, water infiltration, etc., and achieve the effect of avoiding hygienic dead corners, ensuring aesthetics, and being easy to install and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

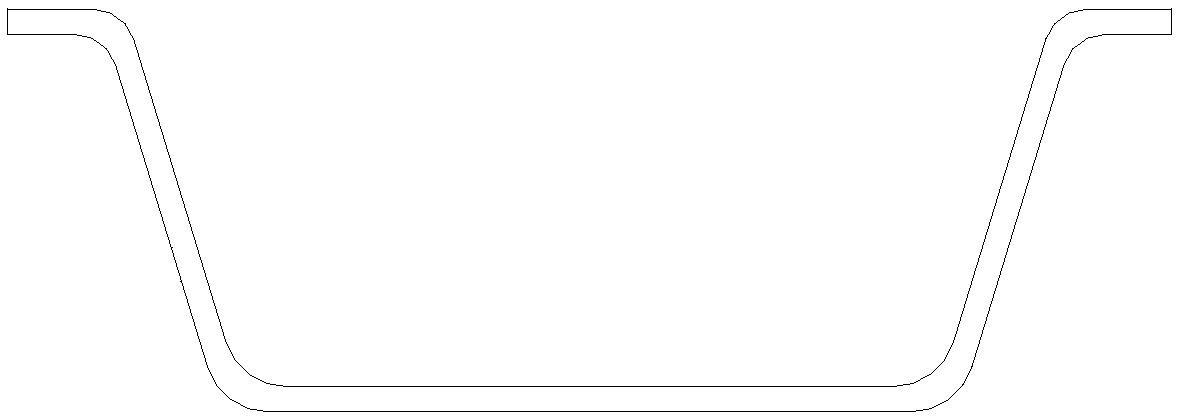

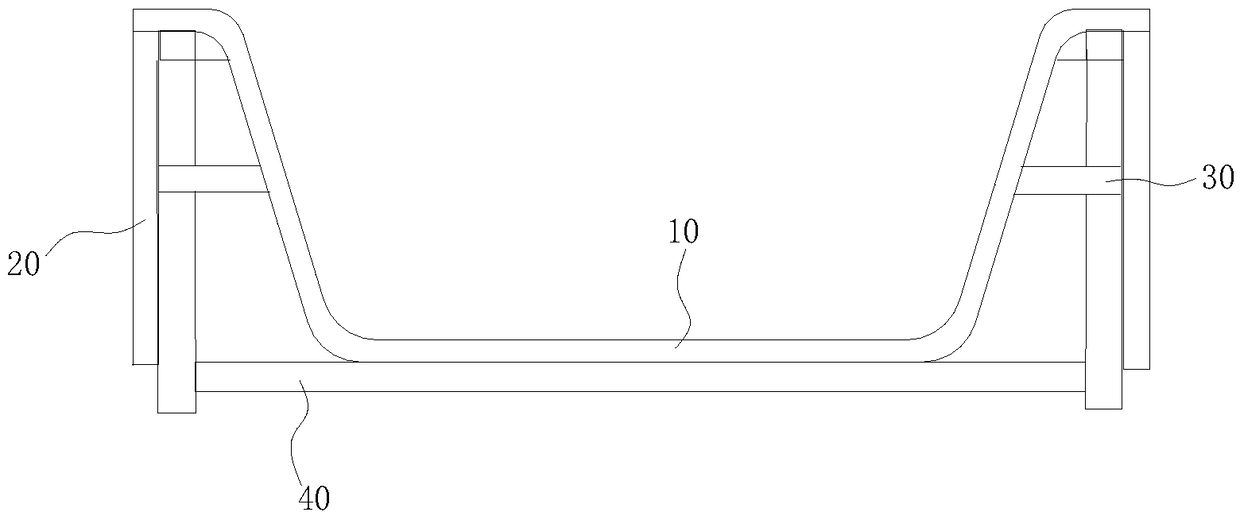

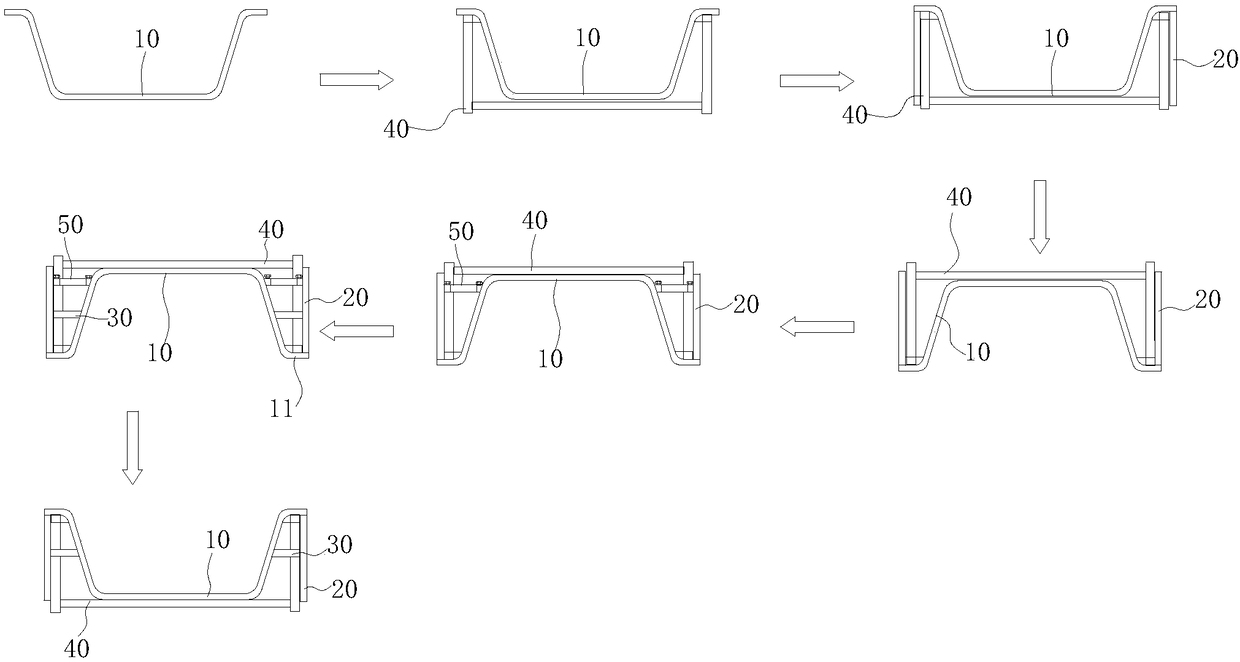

[0014] Such as figure 2 As shown, a bathtub includes a bathtub body 10. The cylinder edge of the bathtub body 10 has a shroud 20 extending downward. The hoarding 20 and the cylinder of the bathtub body 10 are connected as a whole, there is no gap between the two, and there is no water entering the inside, and because the hoarding 20 is set, the outer wall of the bathtub body 10 is blocked. , completely solve the overall aesthetics and no hygienic dead corners; because the peripheral board is not formed by traditional heat-absorbing molding, it is formed by partial heating and bending, and the manufacturing process is simple and energy-saving; After buying the bathtub, you can put the bathtub directly on the ground without building a support platform around the periphery.

[0015] In order to enhance the reliability of the connection between the enclosure 20 and the bathtub body 10 , a connecting support 30 is provided between the enclosure 20 and the bathtub body 10 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com