Method and product for preparing photocatalyst nanomaterial from vanadium-titanium industrial waste residue

A technology of industrial waste slag and nanomaterials, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as the inability to use visible light, ineffective use of vanadium and titanium, and loss of sunlight energy. Good photocatalyst activity and stability, comprehensive utilization rate improvement, photocatalytic activity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of a vanadium-titanium industrial waste slag to prepare photocatalyst nanomaterials

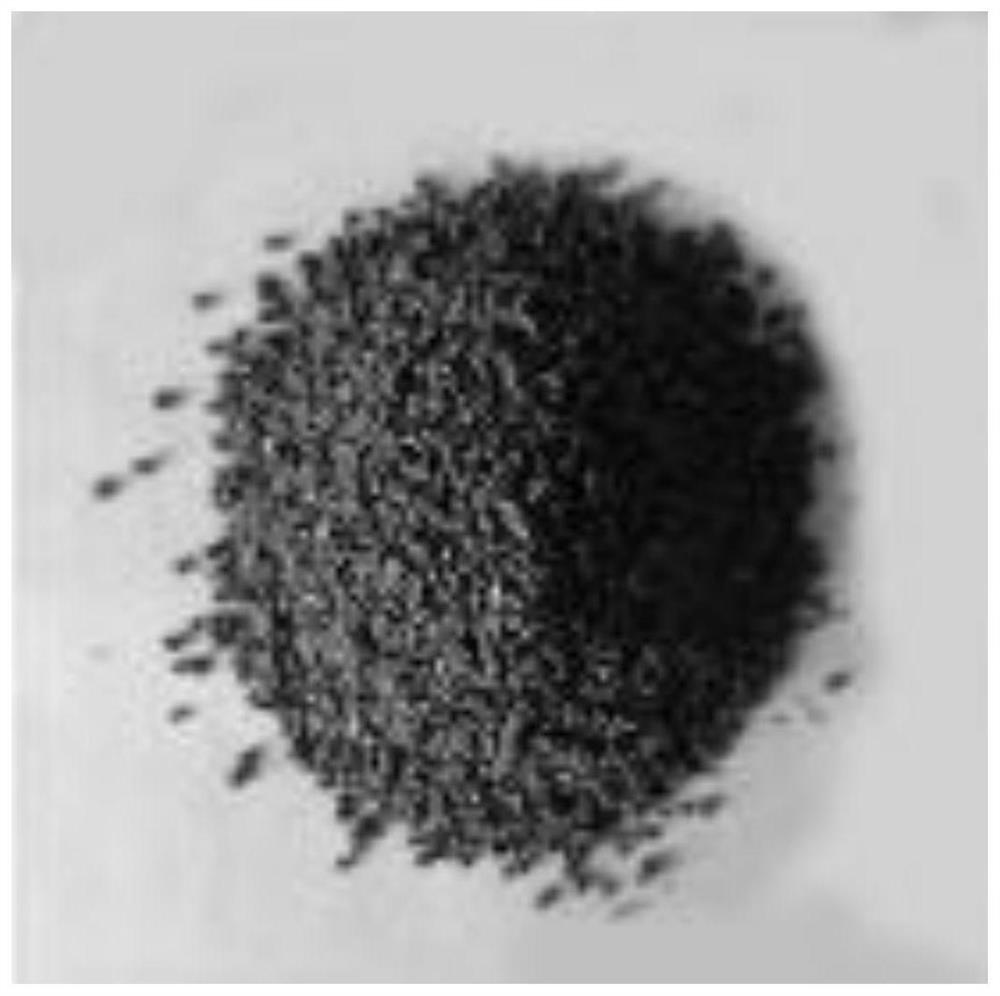

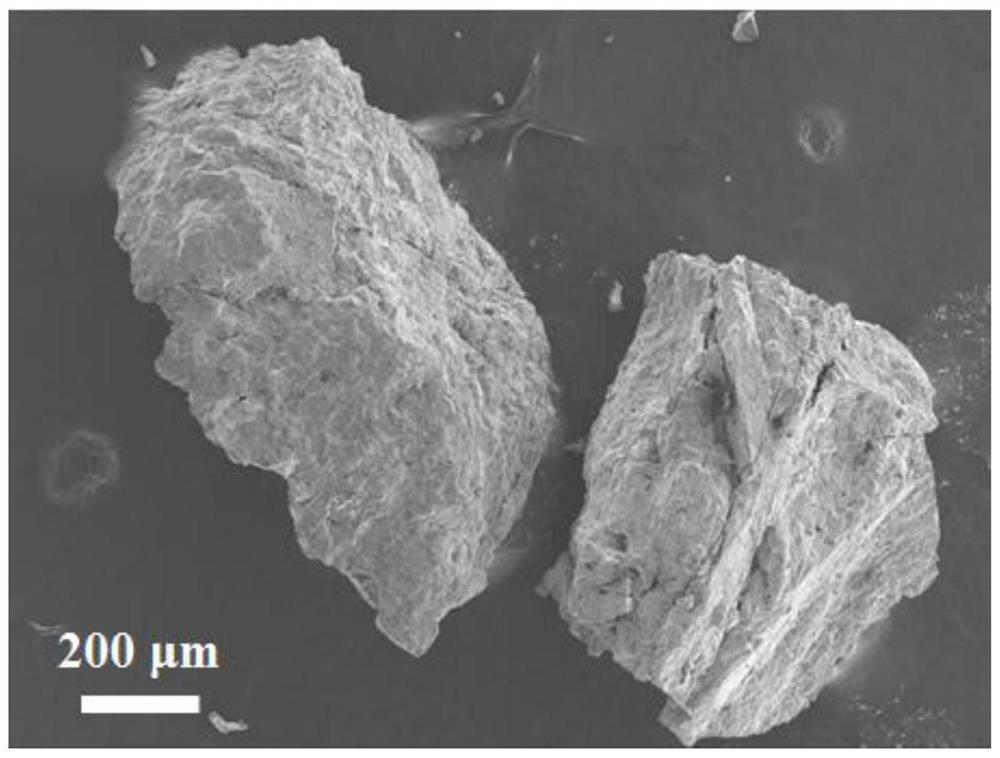

[0039] (1) Put the vanadium-titanium industrial waste residue into a double-pot planetary ball mill and mill for 12 hours, wherein the grinding bowl is 160mL, the grinding sample volume is 50mL, and the zirconia ball with a diameter of 1cm is used as the grinding ball, and the rotational speed during grinding is 200r / min Obtain vanadium-titanium industrial waste slag powder with a particle size of 100nm-5μm;

[0040] (2) Add the vanadium-titanium industrial waste slag powder obtained in step (1) into a reaction kettle containing a sodium hydroxide solution with a pH value of 14.0, and react at 220° C. for 24 hours; the vanadium-titanium industrial waste powder obtained in step (1) The mass volume ratio of waste residue powder to sodium hydroxide solution is 1:20;

[0041] (3) adding the vanadium-titanium industrial waste slag powder treated in step (2) into hydrochloric ac...

Embodiment 2

[0045] Preparation of a vanadium-titanium industrial waste slag to prepare photocatalyst nanomaterials

[0046] (1) Put the vanadium-titanium industrial waste residue into a double-pot planetary ball mill and mill for 12 hours, wherein the grinding bowl is 160mL, the grinding sample volume is 50mL, and the zirconia ball with a diameter of 1cm is used as the grinding ball, and the rotational speed during grinding is 200r / min Obtain vanadium-titanium industrial waste slag powder with a particle size of 100nm-5μm;

[0047](2) Add the vanadium-titanium industrial waste slag powder obtained in step (1) into a reactor containing a potassium hydroxide solution with a pH value of 13.5, and react at 240° C. for 36 hours; the vanadium-titanium industrial waste powder obtained in step (1) The mass volume ratio of waste residue powder and potassium hydroxide solution is 3:50;

[0048] (3) adding the vanadium-titanium industrial waste slag powder after the treatment in step (2) into the n...

Embodiment 3

[0052] Preparation of a vanadium-titanium industrial waste slag to prepare photocatalyst nanomaterials

[0053] (1) Put the vanadium-titanium industrial waste residue into a double-pot planetary ball mill and mill for 12 hours, wherein the grinding bowl is 160mL, the grinding sample volume is 50mL, and the zirconia ball with a diameter of 1cm is used as the grinding ball, and the rotational speed during grinding is 200r / min Obtain vanadium-titanium industrial waste slag powder with a particle size of 100nm-5μm;

[0054] (2) Add the vanadium-titanium industrial waste slag powder obtained in step (1) into a reaction kettle containing a sodium hydroxide solution with a pH value of 15.0, and react at 180° C. for 72 hours; the vanadium-titanium industrial waste powder obtained in step (1) The mass volume ratio of waste residue powder to sodium hydroxide solution is 1:60;

[0055] (3) adding the vanadium-titanium industrial waste slag powder after the treatment of step (2) into a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com