Hair combing machine and hair combing method

A technology of grating machine and screen, which is applied in the direction of chemical instruments and methods, bristles, solid separation, etc. It can solve the problems of difficult removal of fallen roots, unfavorable cleaning and collection, etc., to achieve comprehensive cleaning work, neat bristle cakes, and the number of contacts can be reduced. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

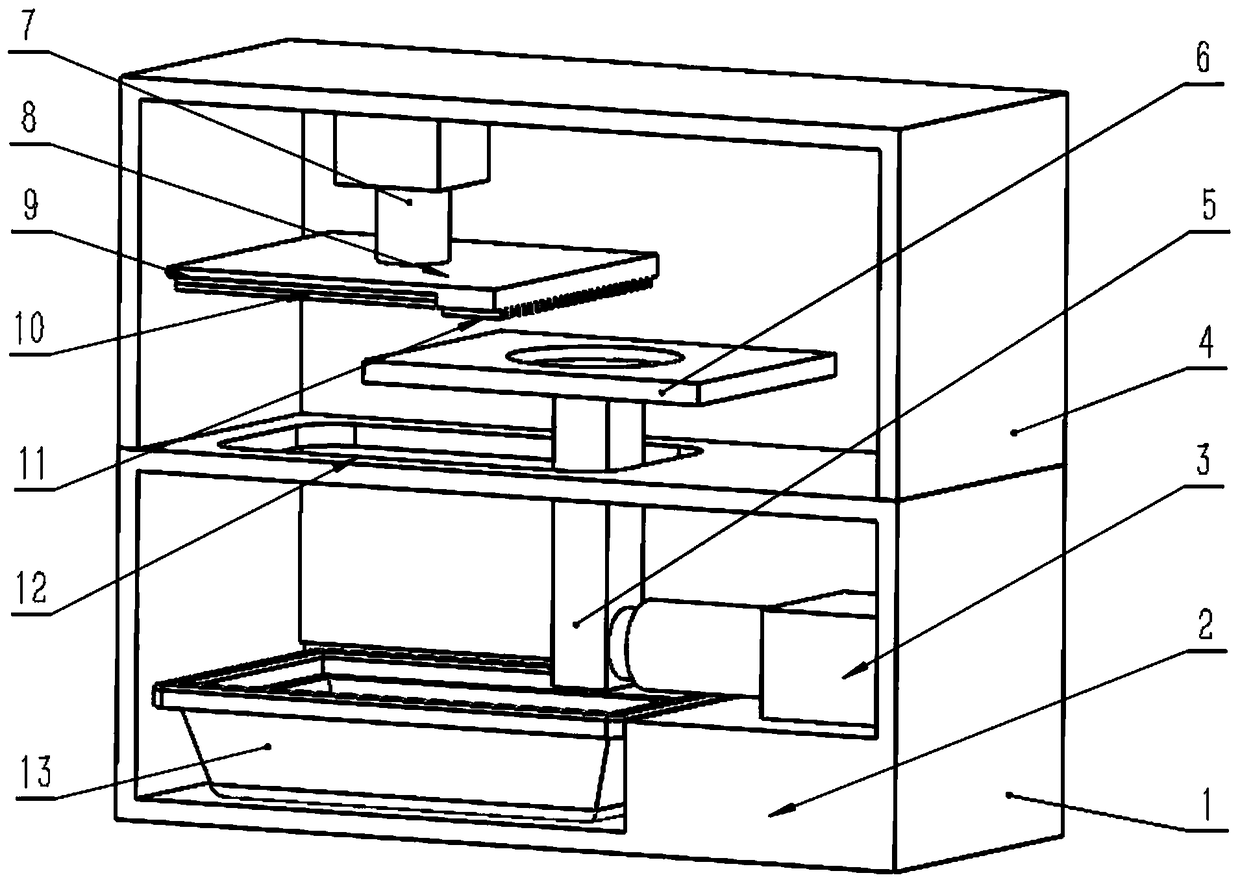

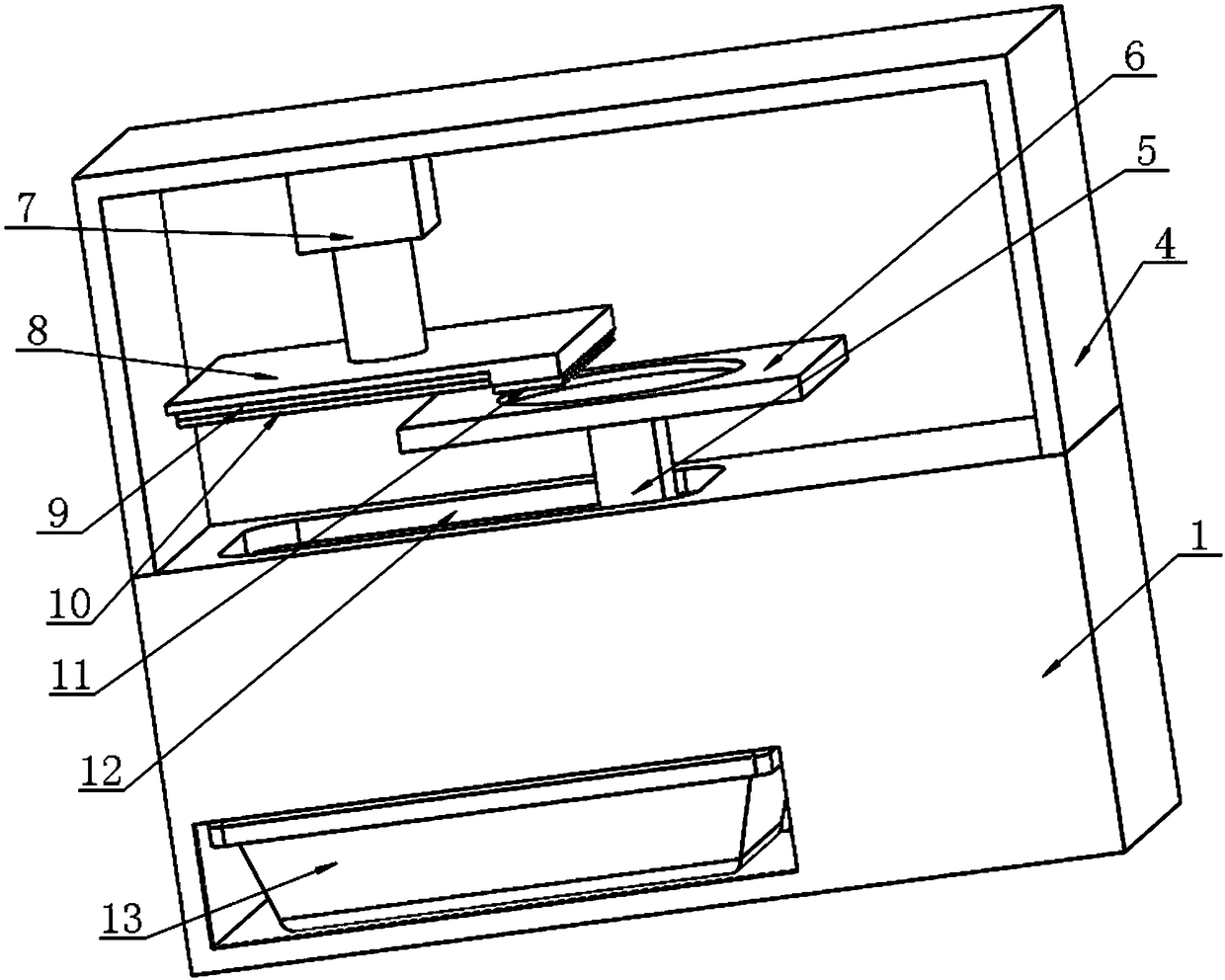

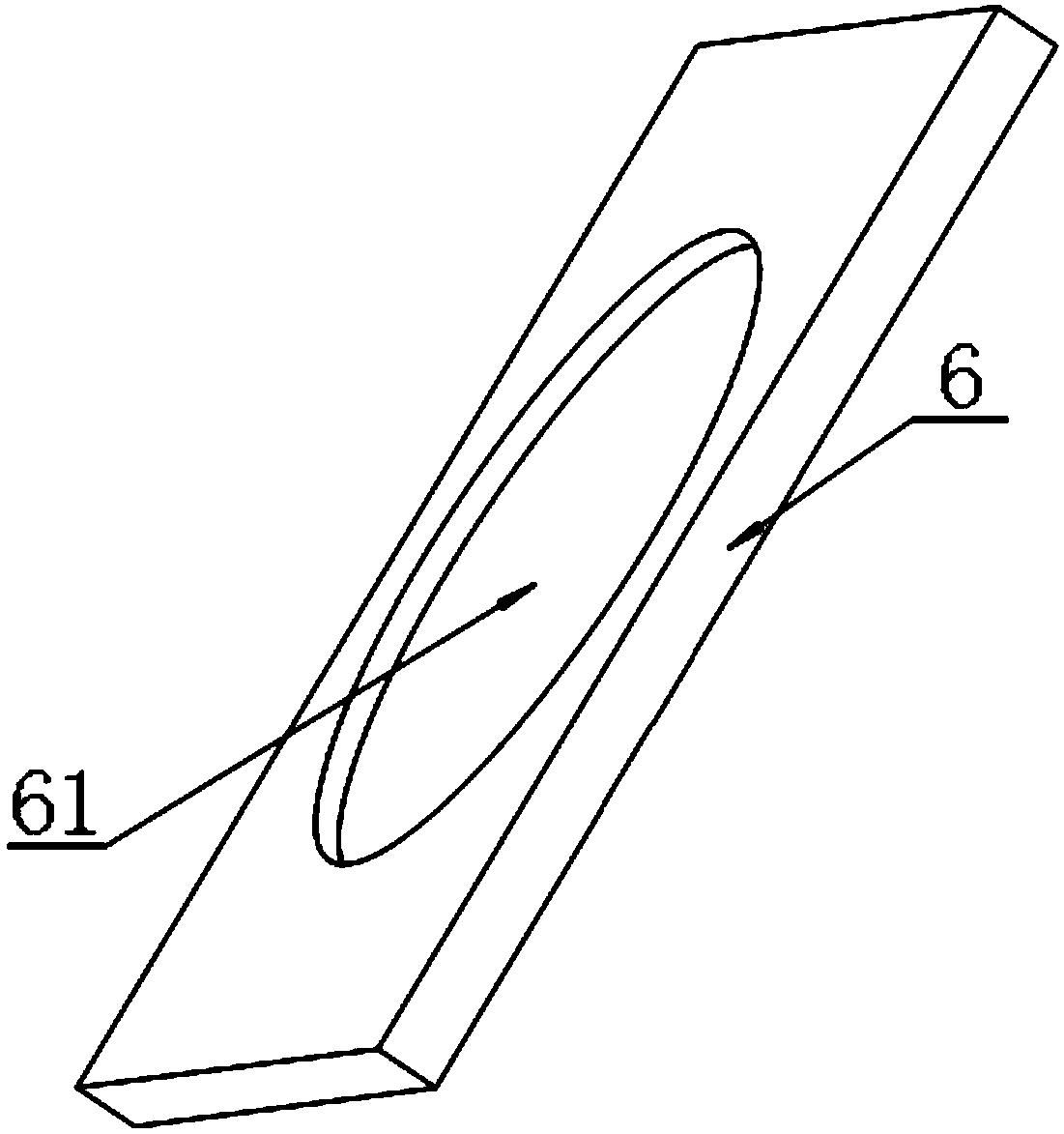

[0050] Place the bristle cake on the feeding tray 6, start the pusher 3 to make the bristle cake reciprocate, when the bristle cake moves to the bottom of the installation plate 8 with two layers of screens, start the lifting member 7, and adjust the installation plate 8 Height, screen cloth and bristle cake contact, and screen cloth moves, clamps the fallen root in the bristle cake, after the bristle cake leaves mounting plate 8, screen cloth resets, releases fallen root, and mounting plate 8 resets, and so reciprocates.

[0051] When combing hair, place the bristle cake on the blind hole 61 of the holding tray 6, start the pusher 3, let the bristle cake reciprocate, let the comb hair assembly and the bristle cake repeatedly contact, when the bristle cake moves to the bottom of the installation plate 8 , start the lifting part 7, adjust the height of the installation plate 8, make the bottom surface of the installation plate 8 contact with the top of the bristle cake, adjust t...

Embodiment 2

[0053] Place the bristle cake on the feeding tray 6, start the lifter 7, adjust the height of the mounting plate 8, start the pusher 3, and make the bristle cake reciprocate. When the bristle cake moves to the bottom of the mounting plate 8 with two layers of screens When the bristle cake is in contact with the screen cloth, the screen cloth moves to clamp the inverted root in the bristle cake. After the bristle cake leaves the mounting plate 8, the screen cloth resets to release the inverted root, and so on and forth.

[0054] When combing hair, the bristle cake is placed on the blind hole 61 of the holding tray 6, the lifting part 7 is started, the height of the mounting plate 8 is adjusted, the bottom surface of the mounting plate 8 is in contact with the top of the bristle cake, and the pusher 3 is started to allow the bristle The cake reciprocates to make the bristle assembly and the bristle cake repeatedly contact. When the bristle cake moves to the bottom of the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com