Ultra-thin seat frame mechanism

A seat frame and seat technology, applied in the direction of seat frames, movable seats, etc., can solve the problem of restricting the layout of the body and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Suitable for four-way car seat cushion

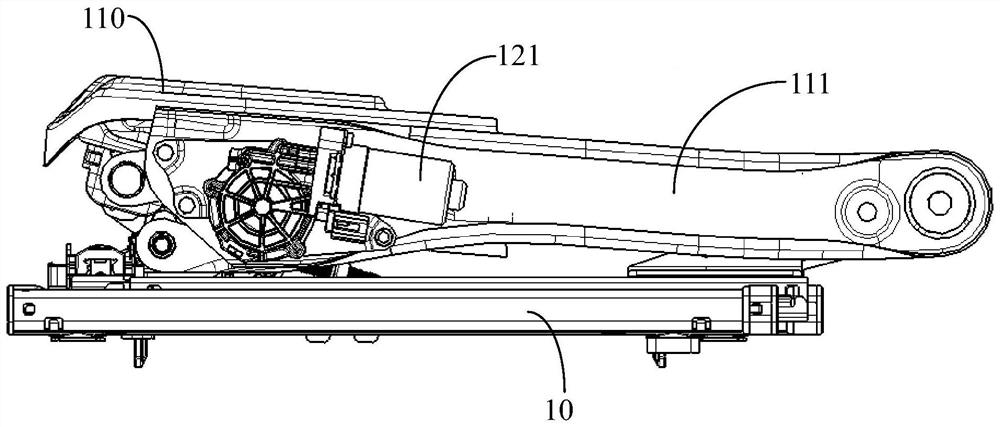

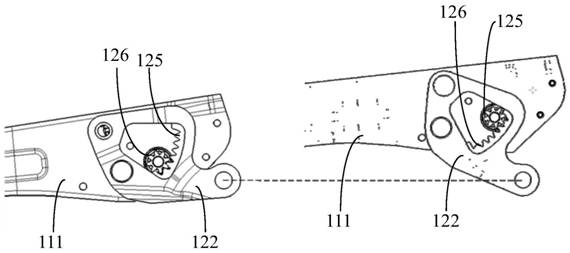

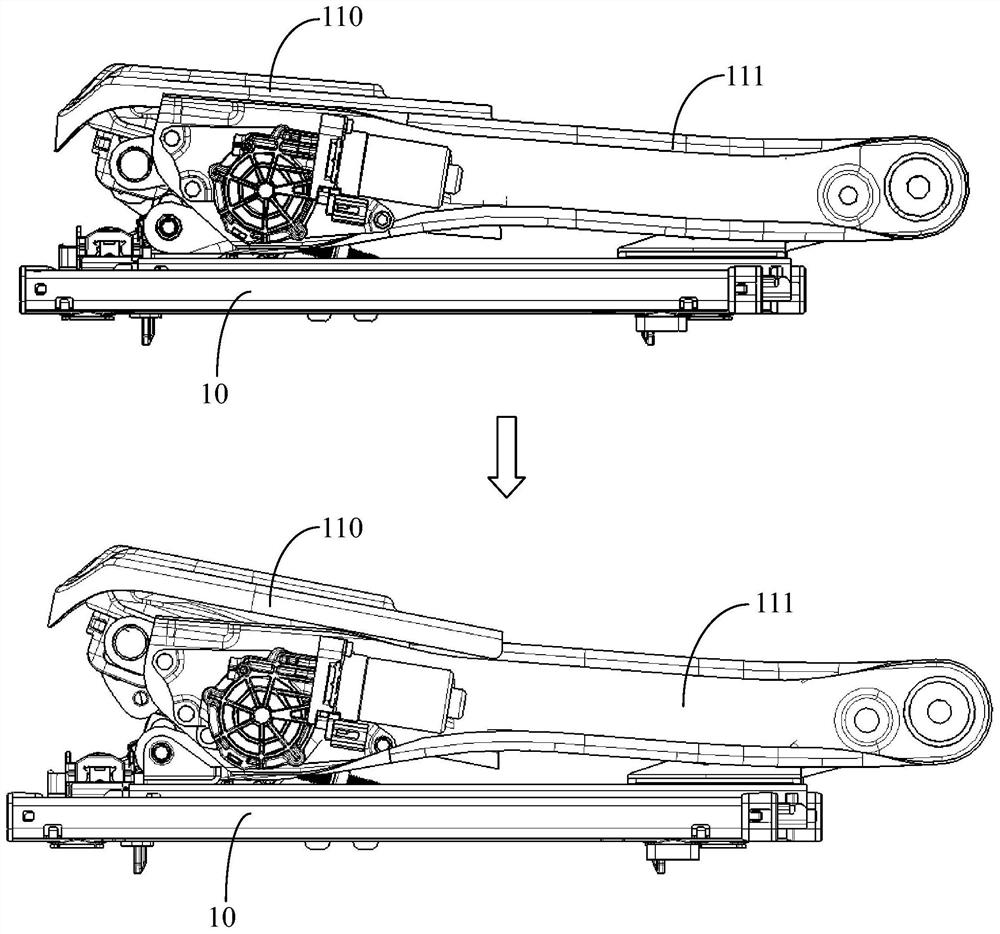

[0044] Such as Figure 3-5As shown, the ultra-thin seat frame mechanism in this embodiment mainly includes a frame frame, a high-profile component and a track component 10 . Wherein, the track assembly 10 is installed on the vehicle body base, and can realize the sliding of the ultra-thin seat frame mechanism in the front-rear direction. The high-profile component is pre-installed between the front part of the seat frame skeleton and the front part of the track component 10 . Specifically, the frame of the seat frame is composed of a basin portion 110 , a first wall plate 111 and a second wall plate 112 , and the first wall plate 111 and the second wall plate 112 are respectively located on lateral sides of the seat basin portion 110 . The high-profile component is composed of a high-profile motor 121, a high-profile plate 122, a high-profile linkage plate 123 and a force transmission rod 124. The upper end of the ...

Embodiment 2

[0050] Example 2: Ultra-thin Seat Frame Mechanism with Rear Support Bars

[0051] Such as Figures 10-14 As shown, an ultra-thin seat frame mechanism with a rear support rod is provided in this embodiment. On the basis of Embodiment 1, other structures are all unchanged, and also have: a track assembly 10, a basin part 110, a first wall plate 111, a second wall plate 112, a high-profile motor 121, a high-profile plate 122 , a high-profile linkage plate 123 , a force transmission rod 124 and two rear linkage plates 13 . Moreover, the connection relationship between the above components is also the same as that in Embodiment 1.

[0052] The difference between this embodiment and embodiment 1 is only:

[0053] In this embodiment, a rear support rod 14 is added at the rear of the frame frame, the rear support rod 14 is made of steel pipe material, and the rear support rod 14 is laterally supported on the first wall plate 111 and the second wall of the frame frame. between th...

Embodiment 3

[0054] Example 3: Suitable for six-way car seat cushion with front lift assembly

[0055] Such as Figure 15-20 As shown, in this embodiment, a kind of ultra-thin seat frame mechanism with a front lifting assembly and a rear support bar is provided (also without a rear support bar, this embodiment is mainly for the high-profile assembly and the front designed for the installation of lifting components). On the basis of embodiment 2, other structures are all unchanged, also have: a track assembly 10, a pot part 110, a first wall plate 111, a second wall plate 112, a high-profile motor 121, a high-profile plate 122, a high-profile linkage plate 123, a force transmission bar 124, two rear linkage plates 13, a rear support bar 14 and two rear support plates 141. Moreover, the connection relationship between the above components is also the same as that in Embodiment 2.

[0056] The difference between this embodiment and embodiment 2 only lies in:

[0057] The seat frame fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com