Small-size light guide plate conveying system

A technology of conveying system and light guide plate, applied in the field of light guide plate conveying and processing, can solve the problems of easy-to-touch products and damage, and achieve the effect of reducing labor costs, lowering defect rate, and reducing human-induced damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

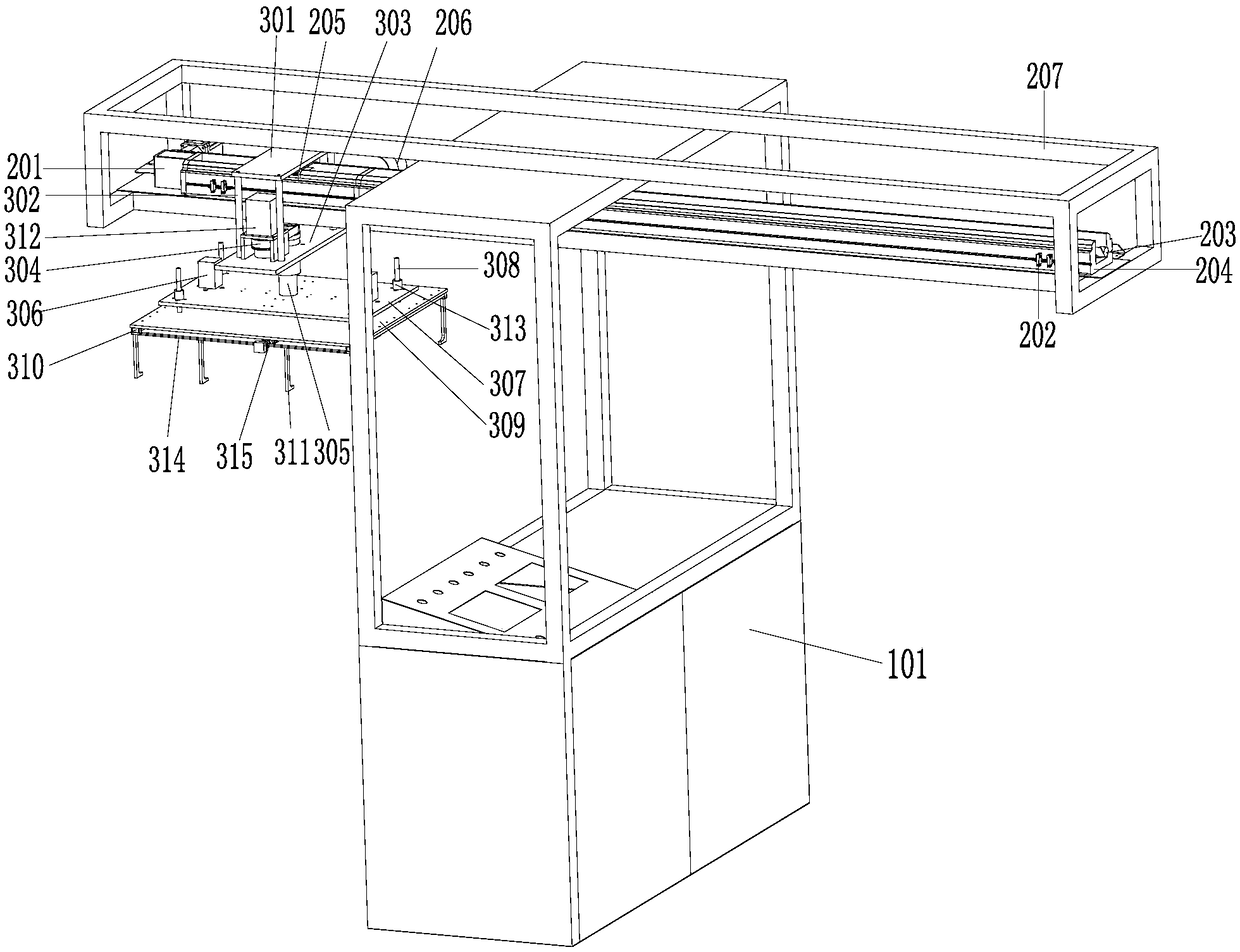

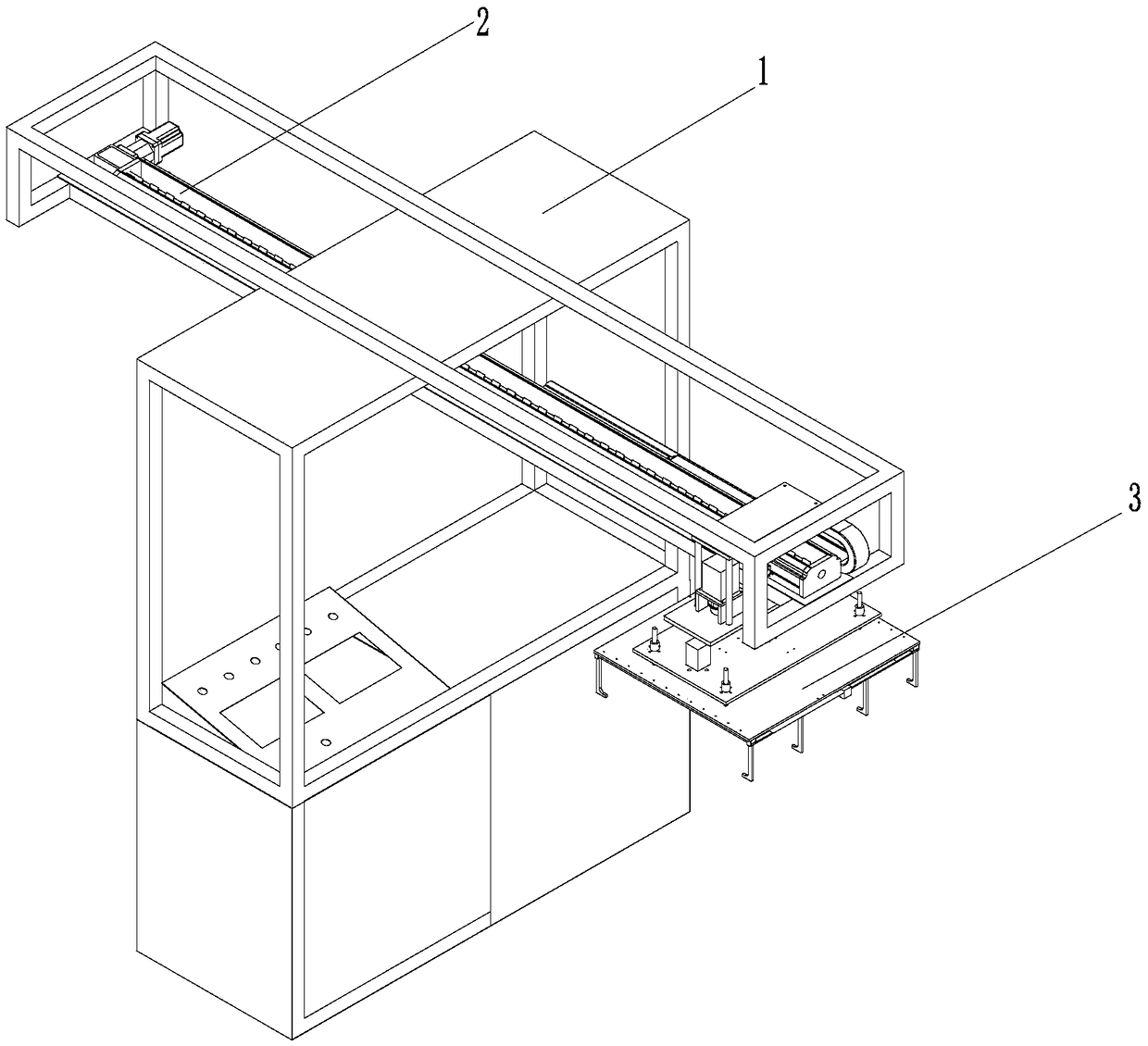

[0024] Such as Figure 1-4 As shown, a small-sized light guide plate transmission system includes a fixing mechanism 1, a screw driving mechanism 2, and a rotating clamping mechanism 3. The fixing mechanism 1 includes a first frame 101, and the screw driving mechanism 2 is installed on the fixing mechanism 1. On the first frame 101, the screw drive mechanism 2 includes a rotary motor 201, an inductor 202, a high-speed precision screw 203, a guide rail 204, a slider 205, a wire slot 206, a second frame 207, and a rotary clamping mechanism 3 Including upper fixed plate 301, fixed plate connecting column 302, support plate 303, belt 304, rotating shaft 305, cylinder 306, fixed plate 307, fixed connecting rod 308, lower fixed plate 309, movable guide rail 310, eight-claw gripper 311, The first rotary motor 312 , the fixed guide rail 313 , the movable rod 314 , the second rotary motor 315 , and the rotary clamping mechanism 3 are installed on the screw drive mechanism 2 .

Embodiment 2

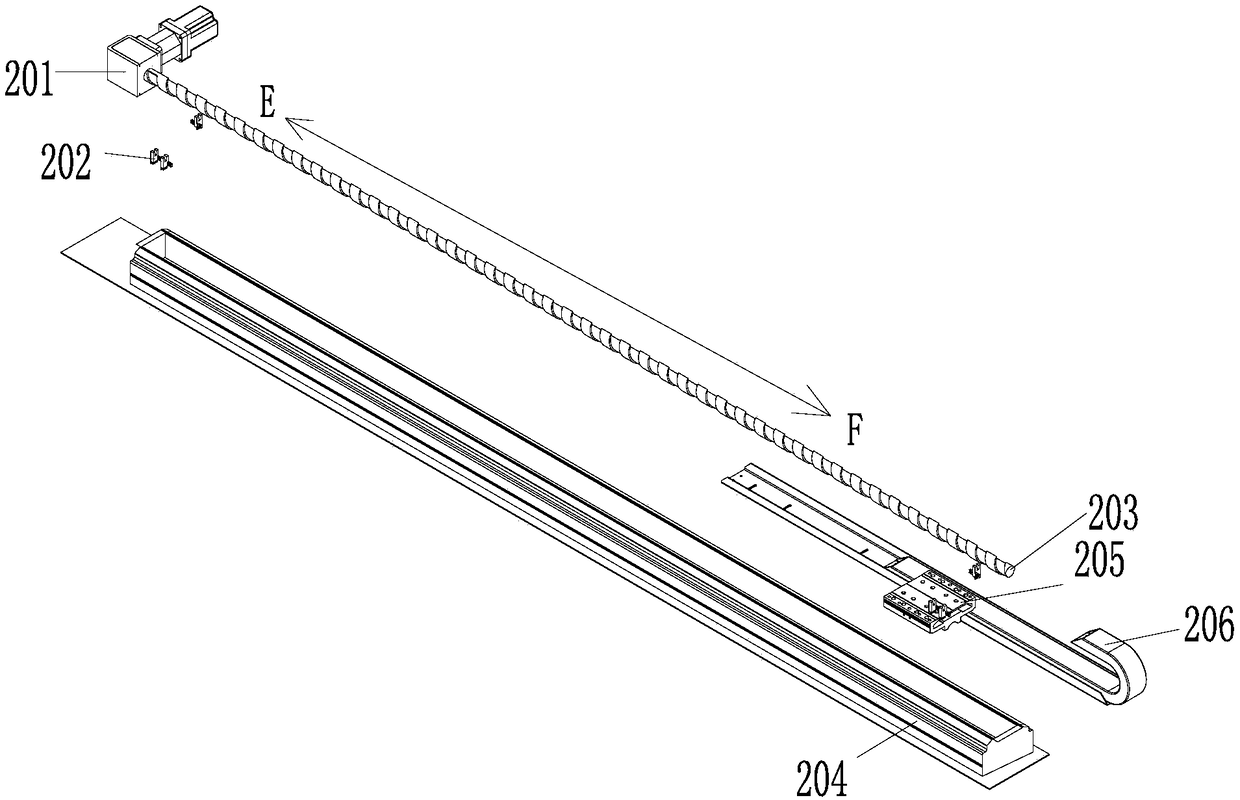

[0026] On the basis of Embodiment 1, the second frame 207 is installed on the first frame 101, the first frame 101 is used to fix the screw drive mechanism 2 and the rotary clamping mechanism 3, and the guide rail 204 is fixedly installed on the second frame. In the middle of the bottom of the inner cavity of the frame 207, the rotary motor 201 is fixedly connected to the left side of the top of the guide rail 204. The high-speed precision screw rod 203 is installed inside the guide rail 204 and connected to the output end of the rotary motor 201. The rotary motor 201 provides high-speed precision wire rods. The rotating power of the rod 203, the slider 205 is installed on the top of the guide rail 204.

Embodiment 3

[0028] On the basis of Embodiments 1 and 2, one end of the bottom of the slider 205 extends to the inside of the guide rail 204 and is threaded with the high-speed precision screw 203. The high-speed precision screw 203 is used to transmit the power of the slider 205, and the bottom of the wire groove 206 One end of the guide rail 204 is fixedly connected to the back of the top right side of the guide rail 204. The guide rail 204 supports the slider 205 and provides guidance. One end of the back of the slider 205 is fixedly connected to the wire groove 206. The number is two, and two sensors 202 are symmetrically fixedly connected to the fronts of the left and right sides of the top of the guide rail 204 , and the sensors 202 are used to control the position of the sensing slider 205 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com