Active-rotation inner-spraying spray head and using method

A rotating head and active technology, which is applied in the field of steel pipe quenching, can solve problems such as excessive distance, nozzle crash, and affecting production efficiency, so as to achieve high-efficiency quenching, reduce impact damage, and increase service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

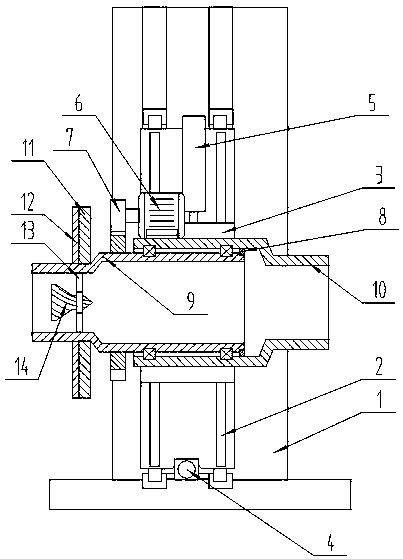

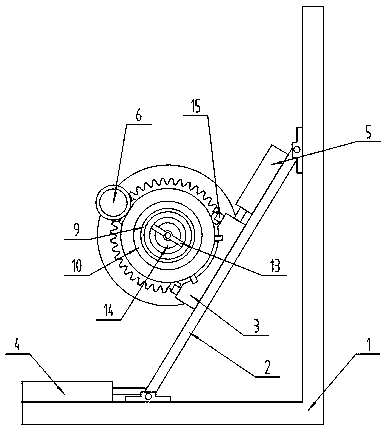

[0017] Referring to Figures 1-2, an active rotating internal spray nozzle includes at least a base frame 1 and a control unit, and is characterized in that it also includes a carriage 2, a carrier frame 3, a first hydraulic cylinder 4, a second hydraulic cylinder 5, and a motor 6. Gear 7, sealing ring 8, nozzle 9 and connecting pipe 10, the base frame 1 is an L-shaped structure, the inner bottom surface and the side wall of the base frame 1 are provided with chute respectively, and the two sides of the sliding frame 2 The end part is slidably connected to the inner bottom surface and side wall of the base frame 1, the first hydraulic cylinder 4 is detachably connected to the inner bottom surface of the base frame 1, and the driving end of the first hydraulic cylinder 4 is movably connected to the sliding frame 2 on the base frame. 1, one end of the inner bottom surface, the carriage 2 is slidably connected to the carriage 3, the second hydraulic cylinder 5 is detachably connect...

Embodiment 2

[0021] On the basis of embodiment 1, with reference to figure 1 , the top plate 11 is fixed on the nozzle pipe 9, and the anti-collision layer 12 is fixed on the top plate 11.

[0022] In actual use: when the pipe is displaced during rotation, the position is restricted by the top plate 11, and it will not continue to move. When it hits the top plate 11, the top plate 11 will follow the rotation of the nozzle 9, so the speed of the top plate 11 is the same as the pipe speed or the difference is small , so that the damage caused by the rotating pipe to the top plate 11 is reduced to the minimum, and the impact damage to the top plate 11 can be reduced through the anti-collision layer 12 at the same time, so as to increase the service life.

Embodiment 3

[0024] On the basis of embodiment 1, with reference to figure 1 and figure 2 , a bracket 13 is fixed inside the nozzle pipe 9 , and a rotating head 14 is fixed inside the bracket 13 .

[0025] The rotating head 14 is conical, and the tip is located on one side of the connecting pipe, and the outer surface of the rotating head 14 is provided with rotating patterns.

[0026] In actual use: after the liquid enters the spray pipe 9, it passes through the rotating head 14 and sprays to the inside of the pipe. Since the outer wall of the rotating head 14 has rotating patterns, when the liquid is ejected, it will be sprayed in an umbrella shape, so that the ejected The liquid is fully sprayed to the inner wall of the pipe to increase the quenching efficiency and effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com