Cloth leveling device for textile spinning

A leveling device and cloth technology, which is applied in the direction of processing textile material equipment configuration, processing textile material drums, processing textile material carriers, etc., can solve problems such as time-consuming and labor-intensive, uneven, and easy-to-wrinkle fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

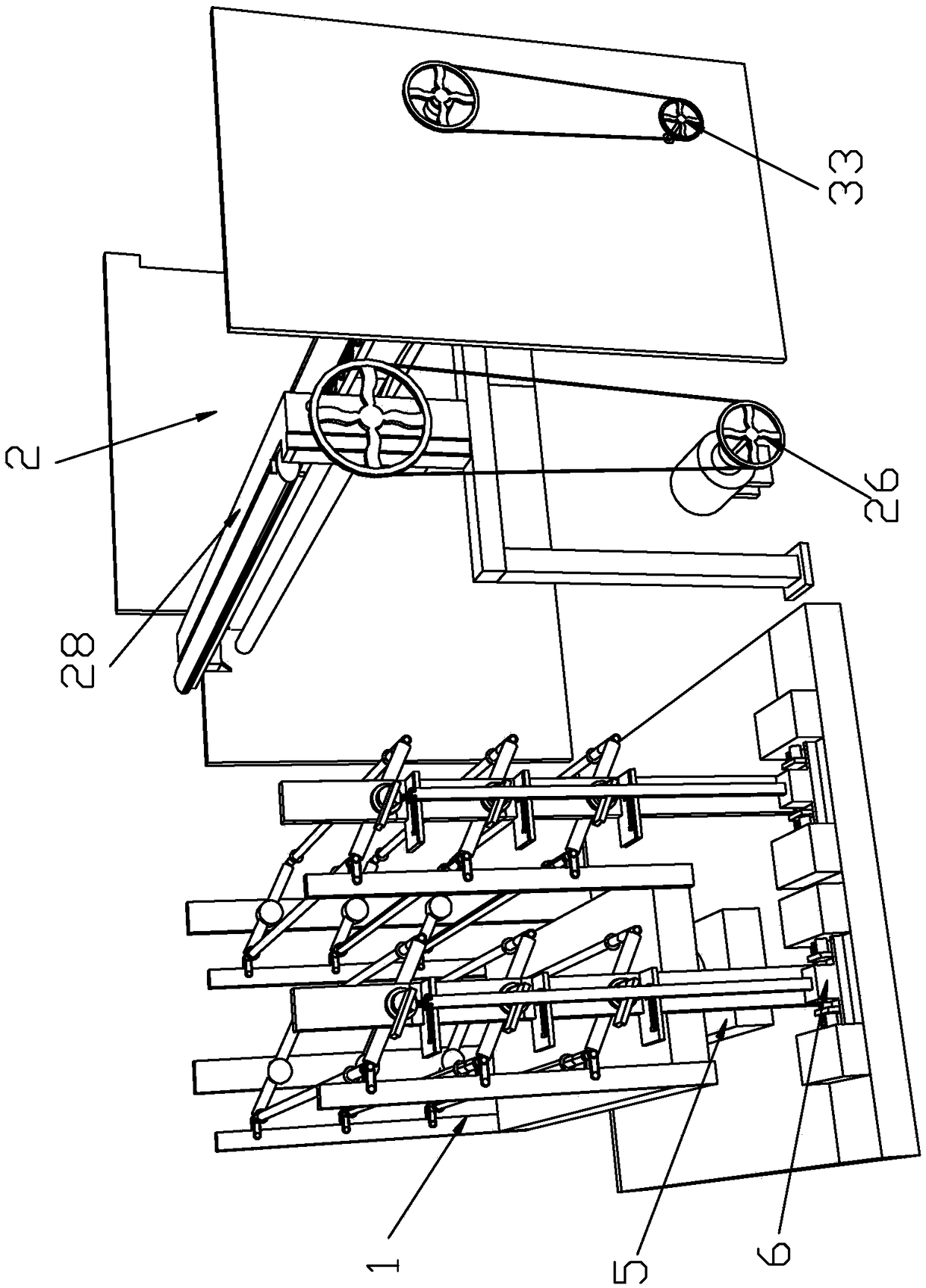

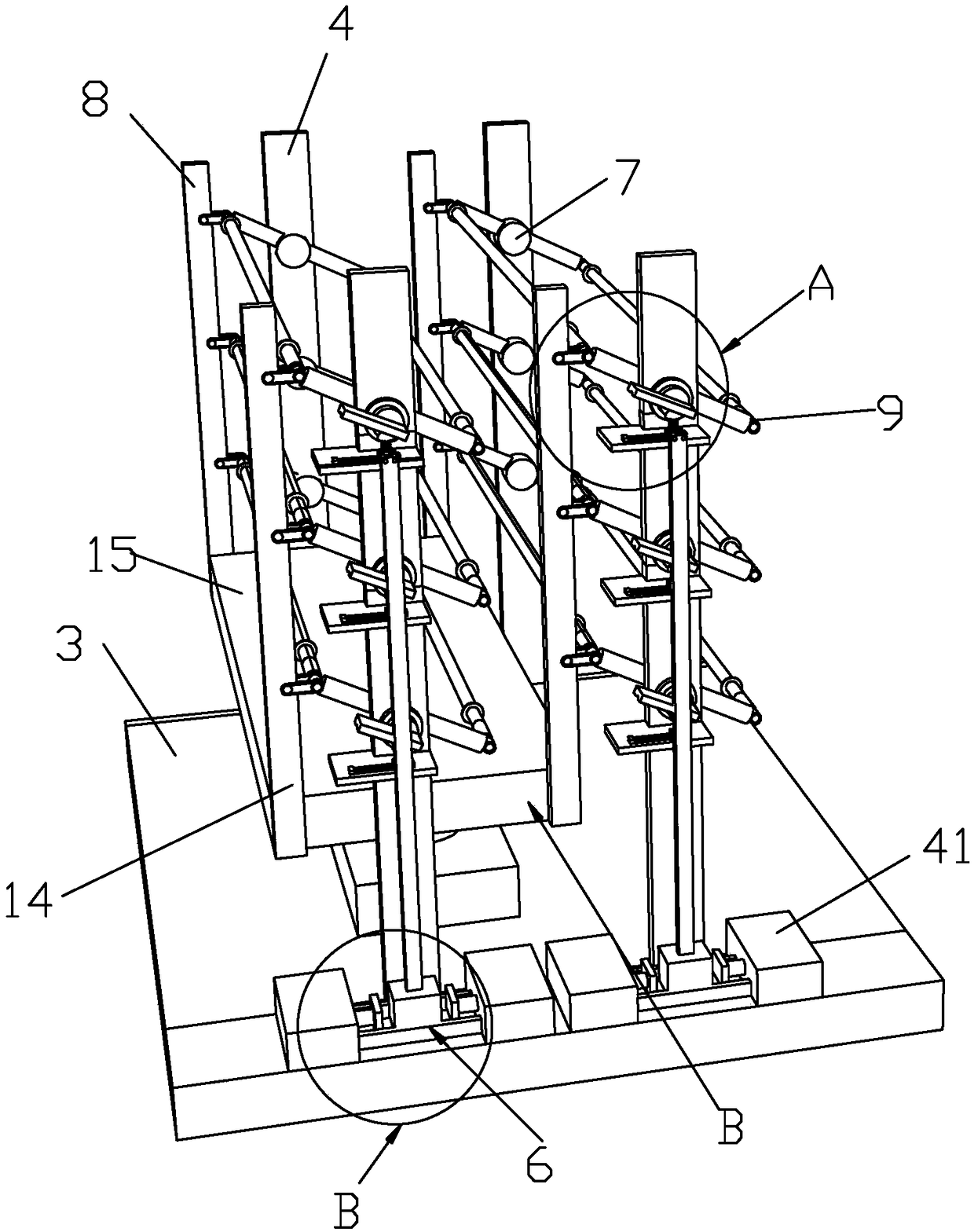

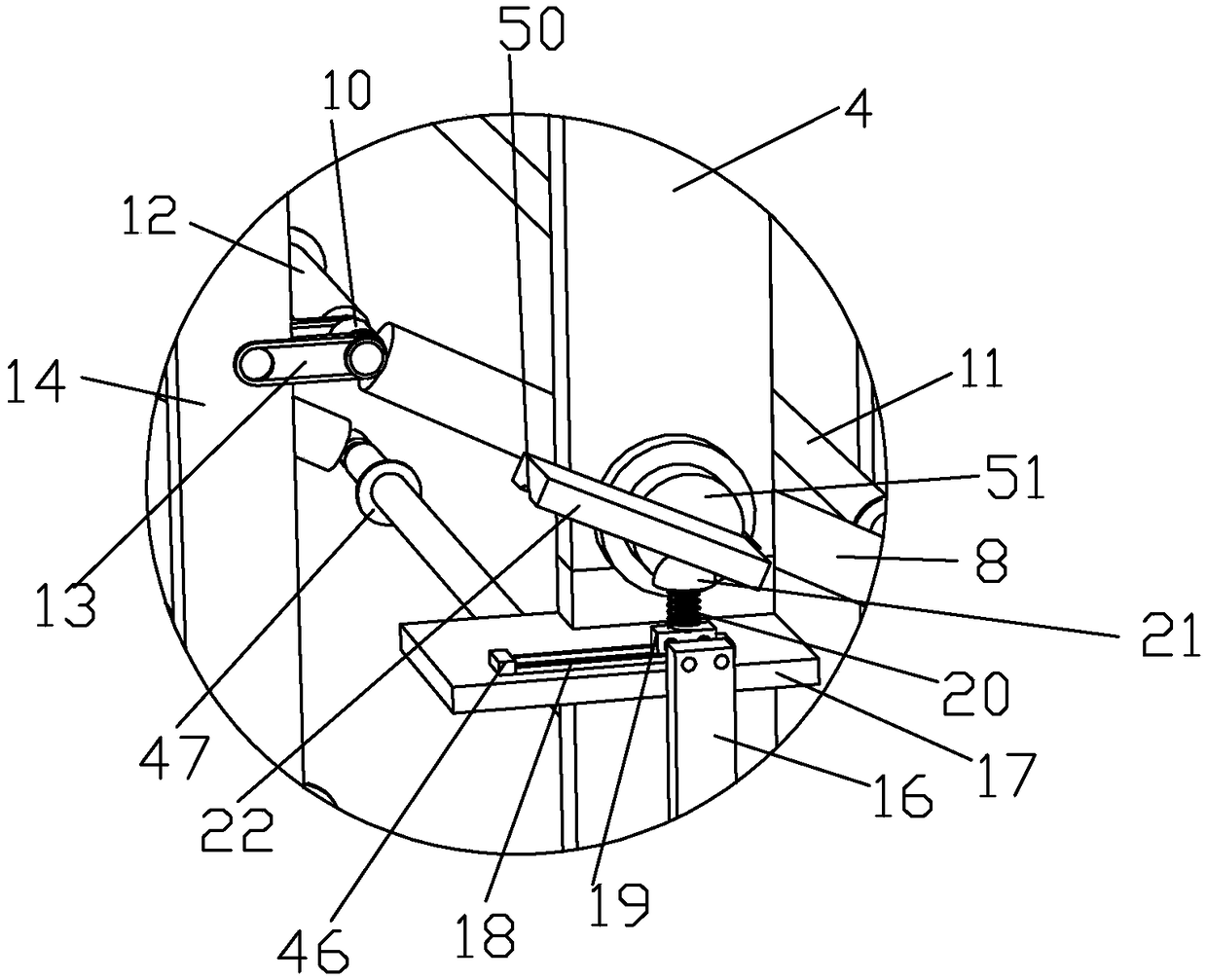

[0027] Such as Figure 1 to Figure 8 As shown in , it is a cloth leveling device for weaving according to the present invention, comprising cloth, a cloth turning machine 1 and a leveling machine 2, the cloth turning machine 1 turns the cloth, and the wrinkles and unevenness of the cloth are adjusted. Turn the cloth to increase the flatness of the cloth; the leveling machine 2 performs high-temperature steam treatment on the cloth to make it heated and leveled; On one side, the fabric turning machine 1 includes a bottom plate 3, a vertical rod 4, a first transmission device 5, a rotating column 7 and a second transmission device 6, the bottom plate 3 is connected to the vertical rod 4, and the vertical rod 4 is connected to the rotating column 7 in rotation. , the rotating column 7 is provided with a rotating rod 8, the two ends of the rotating rod 8 are provided with a first connecting ring 9 and a second connecting ring 10, a first roller shaft 11 is arranged between the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com