Well lid and design method thereof

A manhole cover and cover plate technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as difficulty in opening and closing of manhole cover plates, damage to personnel and items, and achieve the effect of simple structure, convenient inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

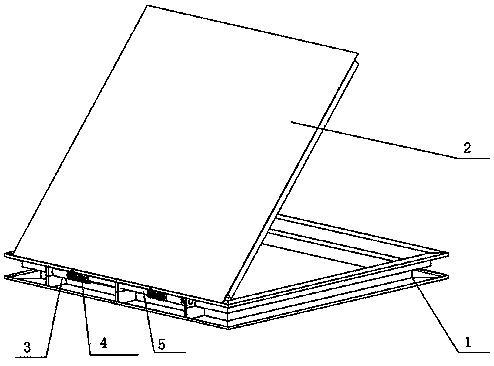

[0015] Such as figure 1 As shown, the present invention includes a base 1 and a cover plate 2; at least two hinge ears 3 are arranged on one side of the cover plate 2; the hinge ears 3 are set on the rotation shaft 5 of the base 1; A torsion spring 4 ; one torsion leg of the torsion spring 4 is fixedly connected to the base 1 , and the other torsion leg is fixedly connected to the cover plate 2 .

[0016] The rotating shaft is installed on the base, and the hinge lug installed on the cover plate with bolts is installed on the rotating shaft to form a rotating pair. The torsion spring is worn on the rotating shaft, one of the torsion legs is lapped on the base, and the other torsion leg is lapped on the cover plate.

[0017] The spring constant is expressed in k, and when the spring is twisted, the load (kgf / mm) is increased by 1° torsion angle.

[0018] E=rigidity modulus of the wire: piano steel wire E=21000, stainless steel wire E=19400, phosphor bronze wire E=11200, brass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com