Inverted taper hole micro electric discharge machining device of fuel injector based on electrode side wall insulation

A technology of sidewall insulation and processing device, applied in electric processing equipment, accessory devices, electrode manufacturing, etc., can solve the problem of inability to form inverted tapered holes, eliminate the suddenness of magnetic field repulsion, soften elastic deformation, and ensure smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

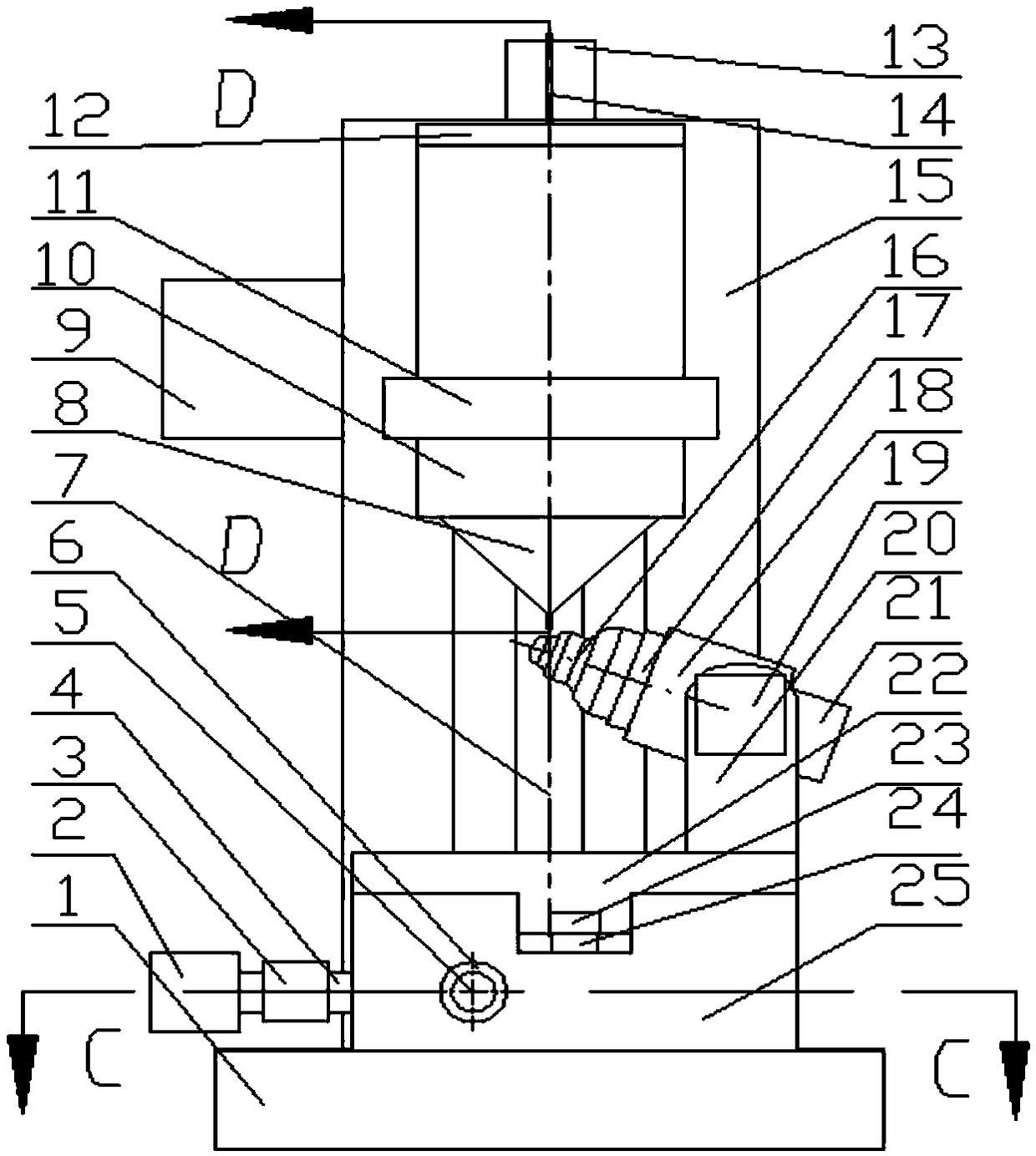

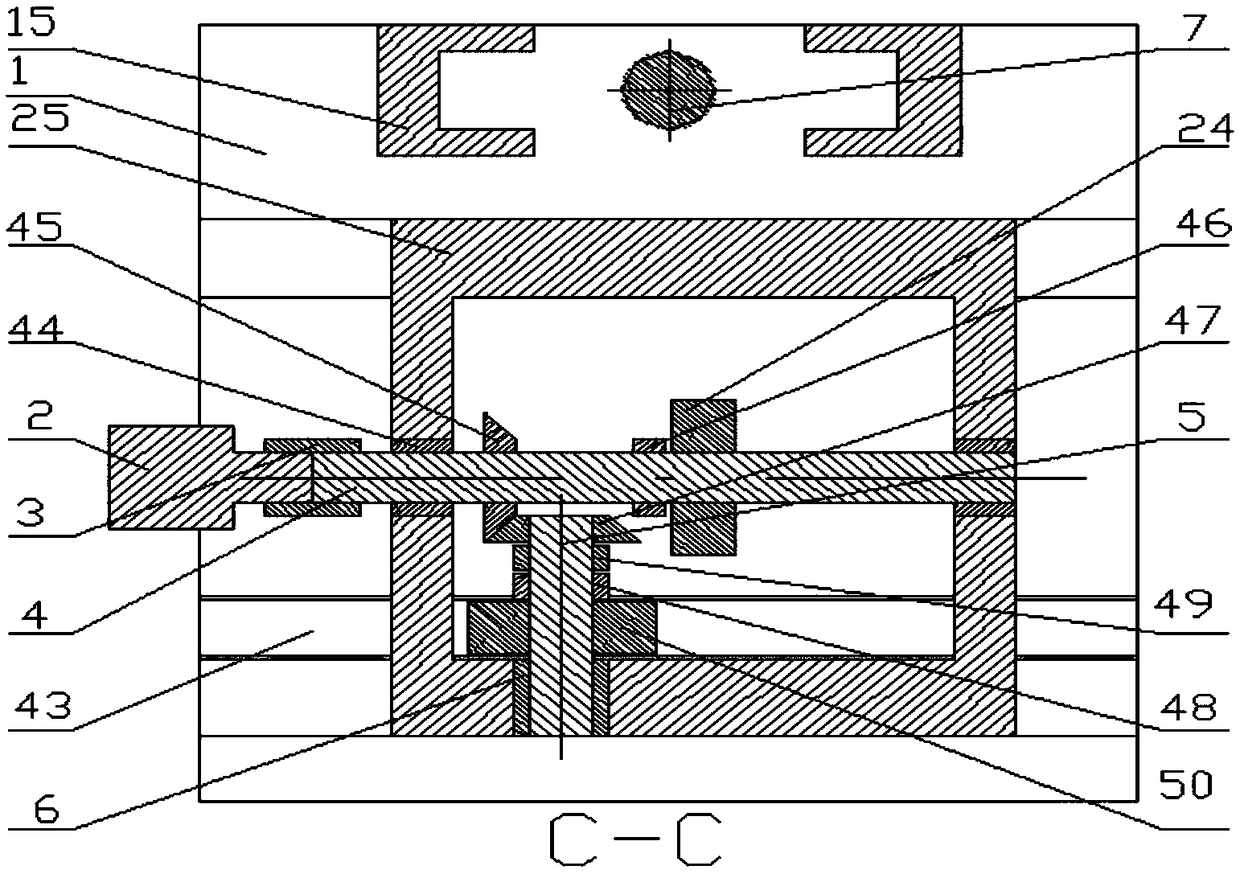

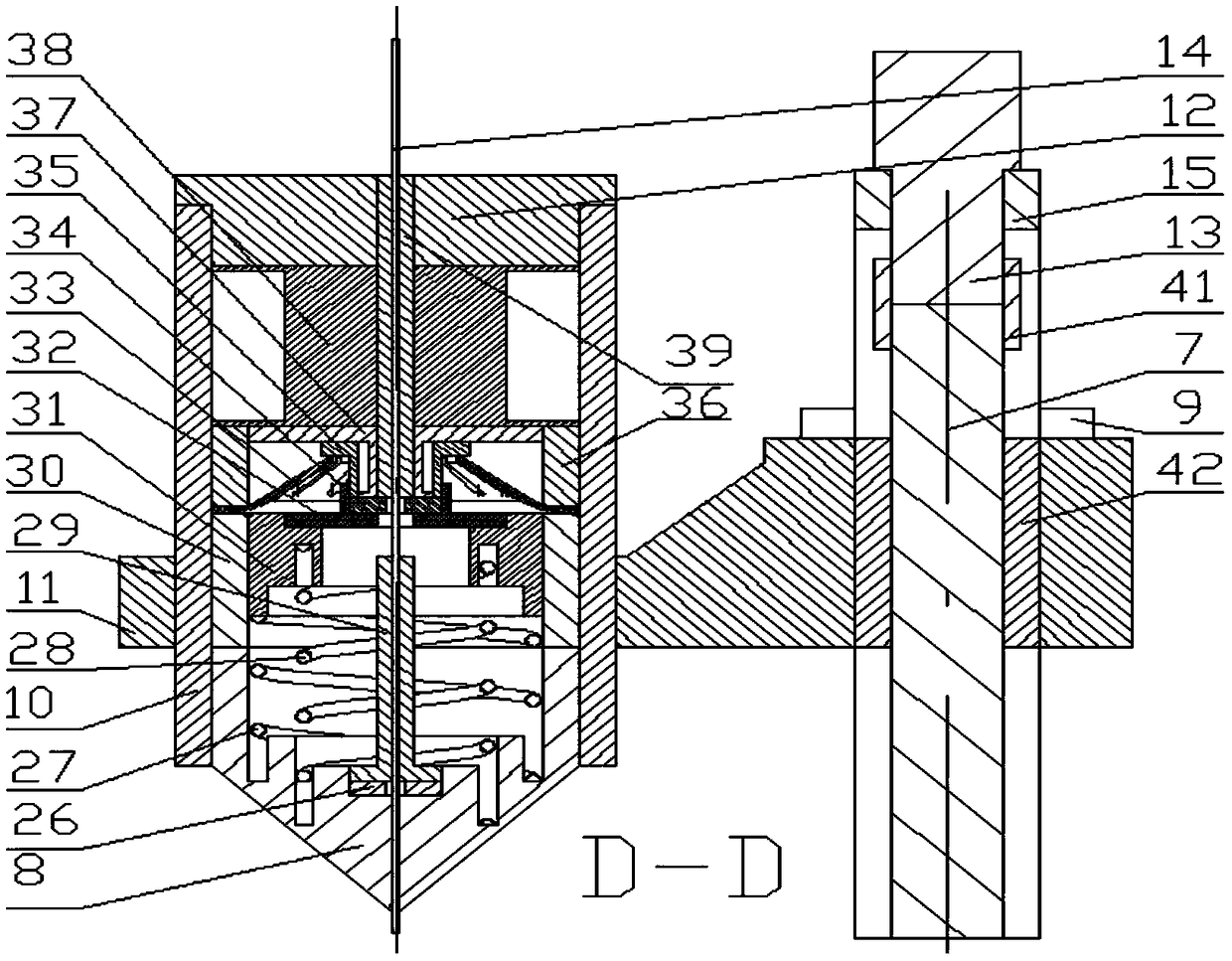

[0040] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0041] see Figure 1-Figure 11 , based on the electrode side wall insulation of the fuel injector reverse taper micro electric discharge machining device, including a fast feed device installed on the support frame 15 and the base plate 1, a micro feed device, a workbench positioning device, a workpiece clamping device and The controllable RC pulse power supply 9 with dynamically adjustable open-circuit voltage connected to the fuel injector 16 and the electrode 14 also includes an electrode 14 with insulated side walls;

[0042] A controllable RC pulse power supply 9 with dynamically adjustable open circuit voltage (such as Figure 12 ) using a smaller discharge capacitor C, (discharge energy Among them, C is the discharge capacitor, V is the open circuit voltage) to realize the fine electric spark discharge, and its open circuit voltage V is gradually and continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com