Floor drain core and floor drain

A floor drain and inner core technology, which is applied to waterway systems, drainage structures, water supply devices, etc., can solve problems such as poor sealing performance of floor drains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

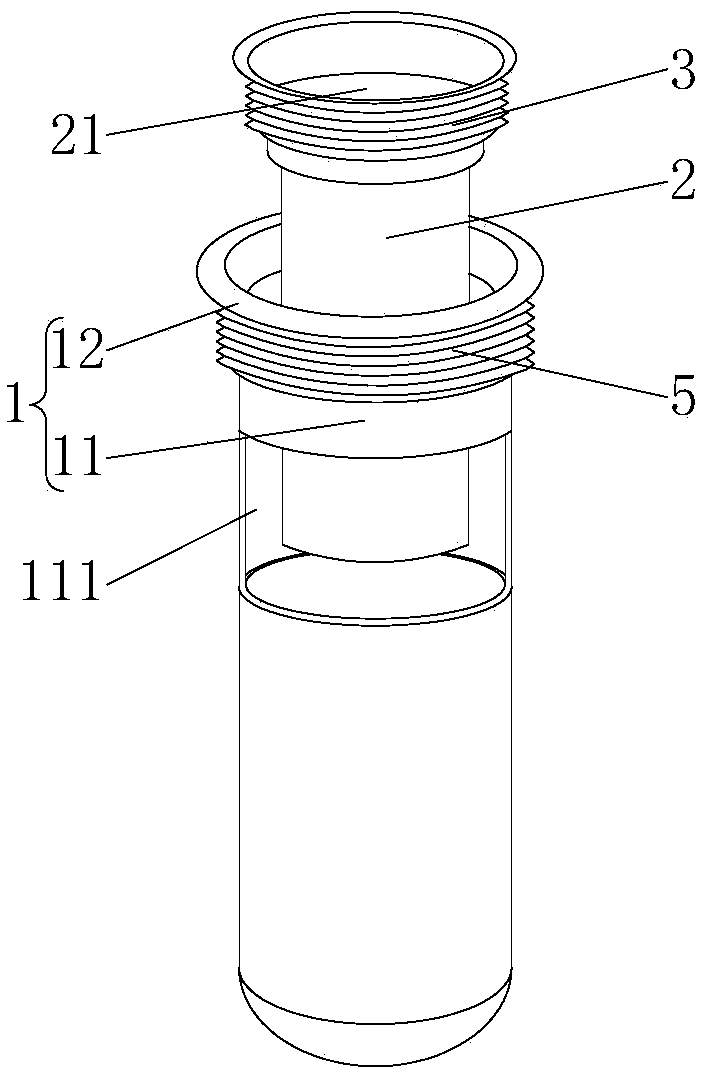

[0034] Such as Figure 1 to Figure 3 As shown, a floor drain core provided in this embodiment includes an outer shell 1 and an inner core 2;

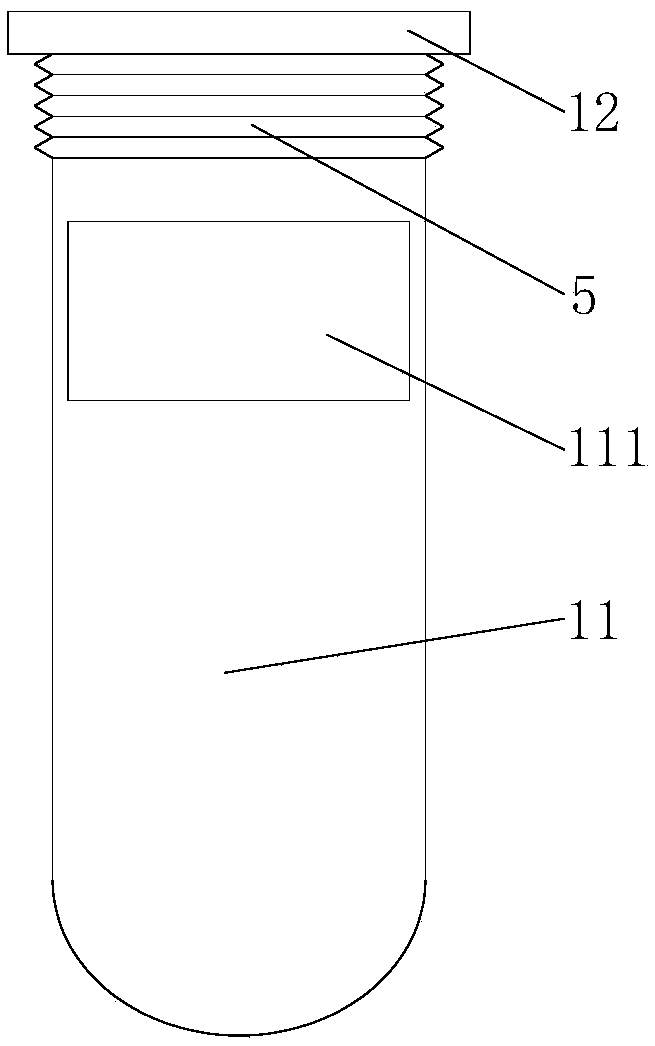

[0035] The shell 1 includes a shell body 11 and a flange 12;

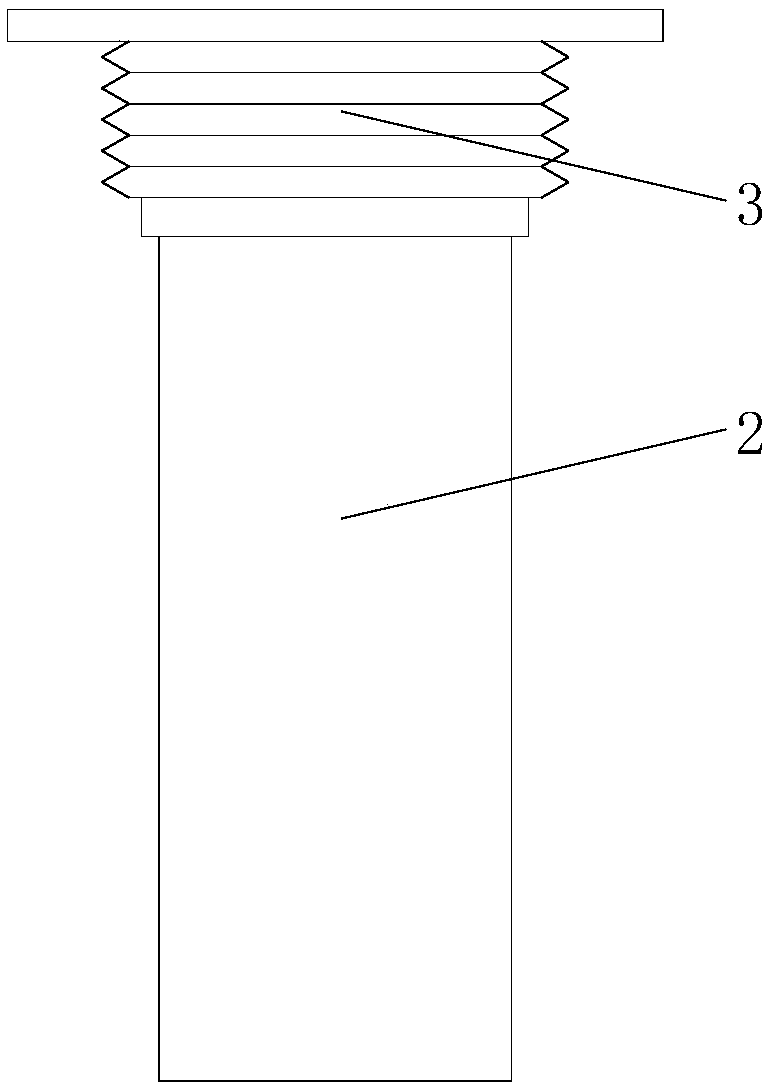

[0036] The inner core 2 is arranged in the outer shell 1, and a first sealing member 3 is arranged between the inner core 2 and the outer shell 1;

[0037] The shell body 11 is provided with at least one drainage port 111, and the bottom of the shell body 11 and the inner core 2 form a water seal area 112;

[0038] A water flow channel 113 is formed between the inner core 2 and the outer shell 1 .

[0039] The floor drain core includes an outer shell 1 and an inner core 2, which are sealed with water as a whole without gaps, effectively preventing harmful substances such as gas, insects, viruses, bacteria, etc. 11 is provided with at least one drain port 111 to drain water at the same time, so that the flow velocity and flow rate of water are maximized, and impurities suc...

Embodiment 2

[0050] This embodiment also provides a floor drain, including the floor drain core provided in Embodiment 1 above, and also includes a floor drain installation plate 4;

[0051] A mounting part 51 is provided on the floor drain mounting plate 4;

[0052] The flange 12 is installed on the floor drain installation plate 4 through the installation portion 51 , and the second sealing member 5 is arranged between the housing 1 and the floor drain installation plate 4 .

[0053]The floor drain includes a floor drain core and a floor drain installation plate 4, and a second sealing member 5 is arranged between the floor drain core and the floor drain, eliminating the gap between the floor drain installation plate 4 and the shell 1, and limiting the path for water to enter the pipeline. It can enter from the inner core 2, and be discharged from the water reservoir through the water channel 113, while preventing gas, insects, viruses, bacteria and other harmful substances in the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com