A debris catcher for cement slurry pouring

A technology of cement slurry and salvage, which is applied in building construction, processing of building materials, construction, etc., can solve problems such as wasting time and salvage difficulty, and achieve the effect of saving time and reducing the difficulty of salvage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

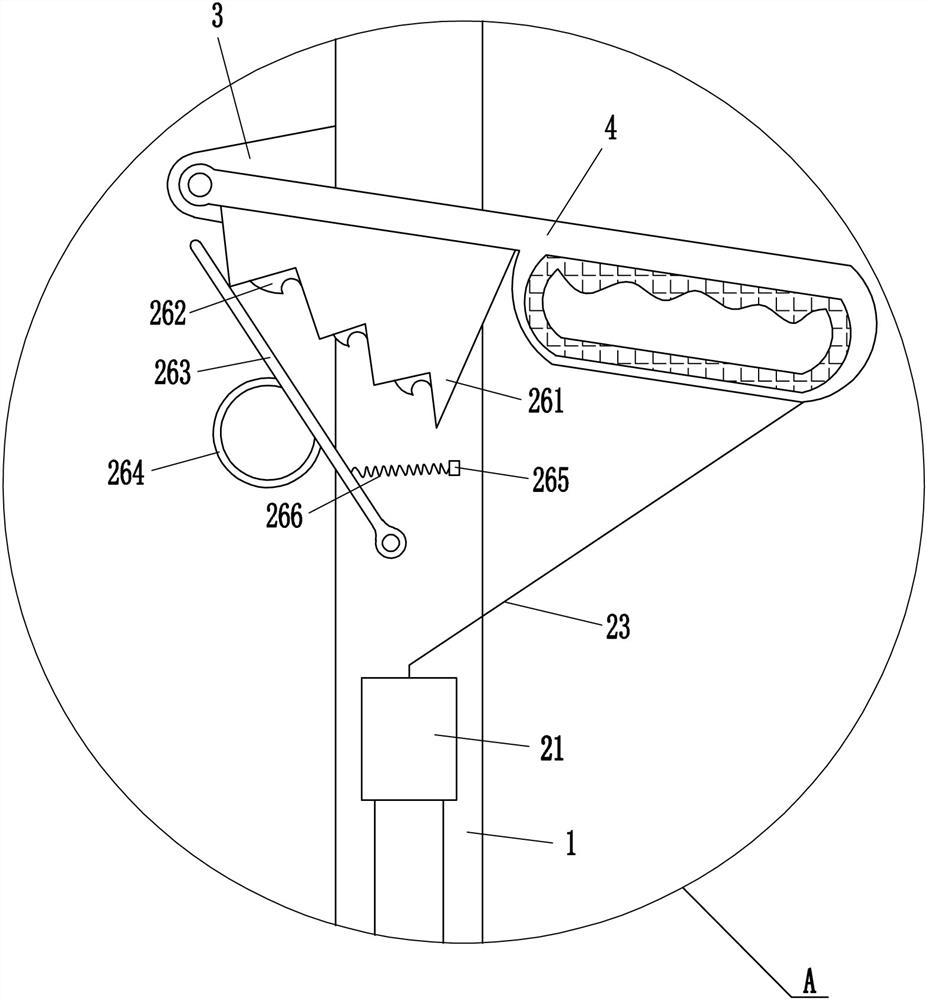

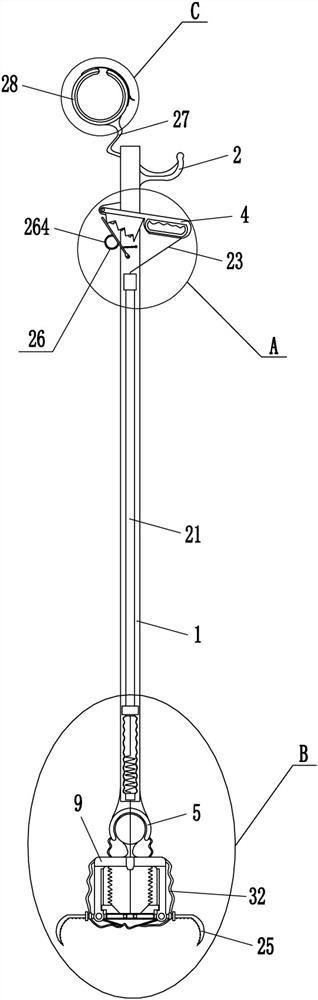

[0016] A debris catcher for cement slurry pouring, such as Figure 1-3 As shown, it includes a support rod 1, a fixed grip rod 2, a vertical plate 3, a movable grip rod 4, a semicircular frame 5, a round ball 6, a large bellows 7, a connecting block 8, a mounting plate 9, and a vertical rod 10 , slider 12, first spring 13, return-shaped frame 14, swing lever 15, roller 16, pull cord 17, guide sleeve 18, wire sleeve 19, small bellows 20, wire guide 21, second spring 22, pull wire 23. The connecting plate 24 and the clamp 25, the upper right side of the support rod 1 is fixedly connected with the fixed handle 2, the support rod 1 is connected with the fixed handle 2 by welding, and the upper left side of the support rod 1 is fixedly connected with the vertical plate 3 , the pole 1 is connected to the riser 3 by welding, the front side of the riser 3 is rotatably connected to a movable handle 4, the bottom end of the pole 1 is fixedly connected with a semicircular frame 5, and th...

Embodiment 2

[0018] A debris catcher for cement slurry pouring, such as Figure 1-3 As shown, it includes a support rod 1, a fixed grip rod 2, a vertical plate 3, a movable grip rod 4, a semicircular frame 5, a round ball 6, a large bellows 7, a connecting block 8, a mounting plate 9, and a vertical rod 10 , slider 12, first spring 13, return-shaped frame 14, swing lever 15, roller 16, pull cord 17, guide sleeve 18, wire sleeve 19, small bellows 20, wire guide 21, second spring 22, pull wire 23. The connecting plate 24 and the fixture 25, the upper right side of the support rod 1 is fixedly connected with the fixed handle 2, the upper left side of the support rod 1 is fixedly connected with the vertical plate 3, and the front side of the vertical plate 3 is connected with the movable handle 4 in a rotational manner, A semicircular frame 5 is fixedly connected to the bottom of the pole 1, a round ball 6 is arranged inside the semicircular frame 5, a large bellows 7 is fixedly connected to t...

Embodiment 3

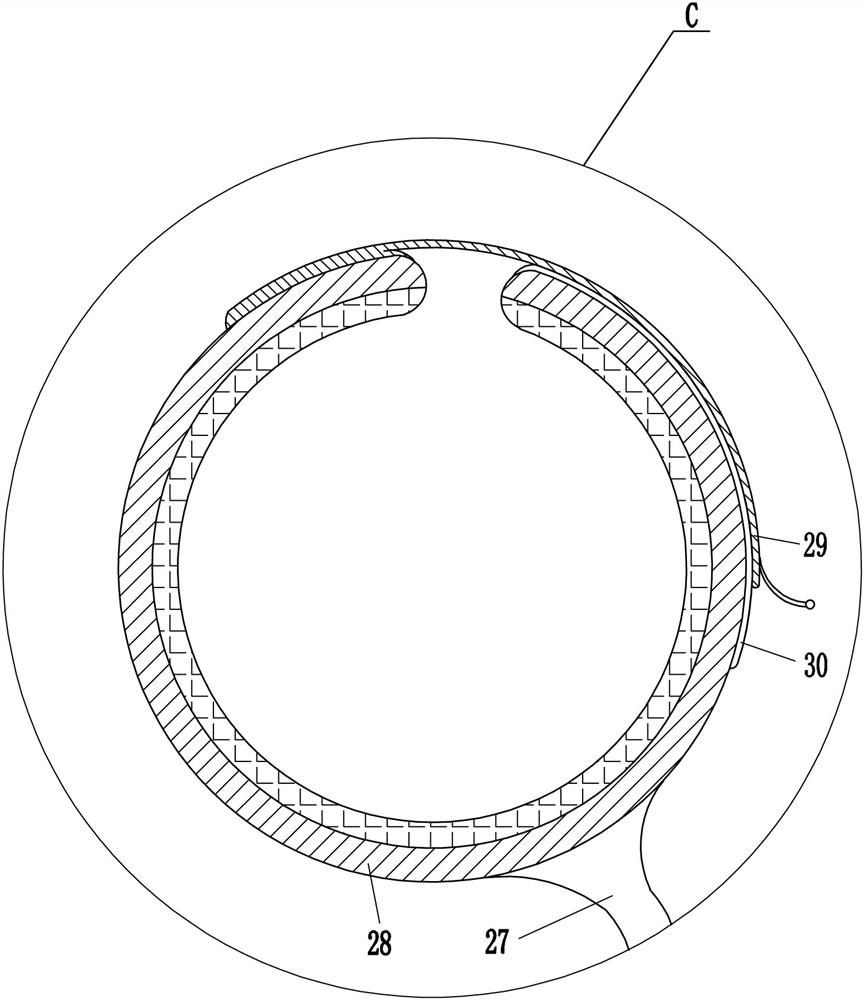

[0021] A debris catcher for cement slurry pouring, such as Figure 1-4As shown, it includes a support rod 1, a fixed grip rod 2, a vertical plate 3, a movable grip rod 4, a semicircular frame 5, a round ball 6, a large bellows 7, a connecting block 8, a mounting plate 9, and a vertical rod 10 , slider 12, first spring 13, return-shaped frame 14, swing lever 15, roller 16, pull cord 17, guide sleeve 18, wire sleeve 19, small bellows 20, wire guide 21, second spring 22, pull wire 23. The connecting plate 24 and the fixture 25, the upper right side of the support rod 1 is fixedly connected with the fixed handle 2, the upper left side of the support rod 1 is fixedly connected with the vertical plate 3, and the front side of the vertical plate 3 is connected with the movable handle 4 in a rotational manner, A semicircular frame 5 is fixedly connected to the bottom of the pole 1, a round ball 6 is arranged inside the semicircular frame 5, a large bellows 7 is fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com