Anti-clamping mechanism of TMR magneto-resistance sensor

A technology of magnetoresistive sensor and rotational speed sensor, applied in the field of intelligent anti-pinch, can solve problems such as customer injury to children, electric door without anti-pinch function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

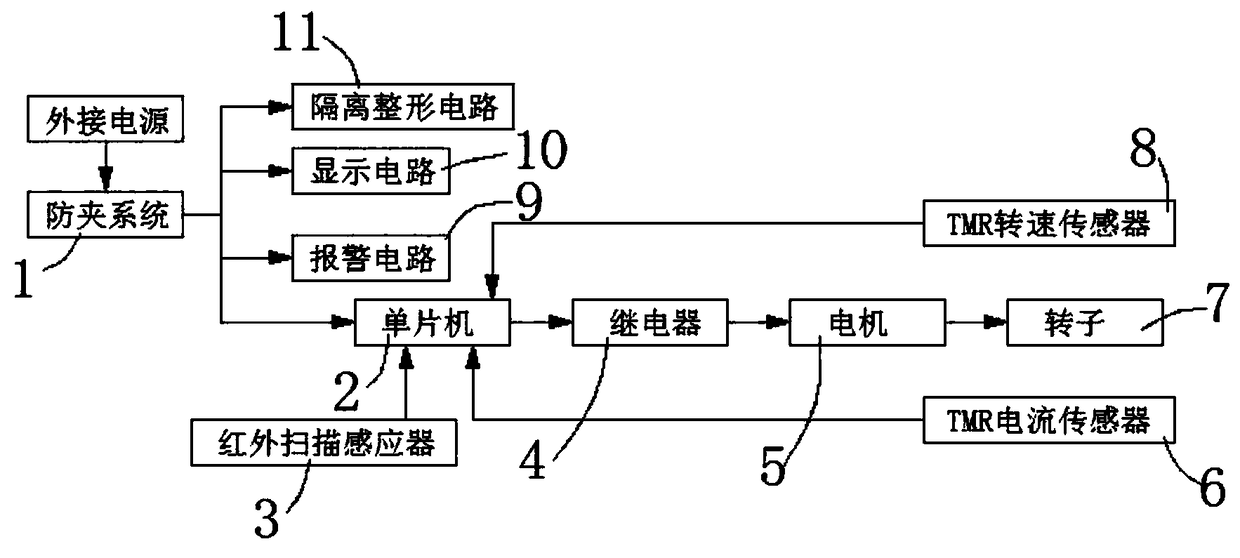

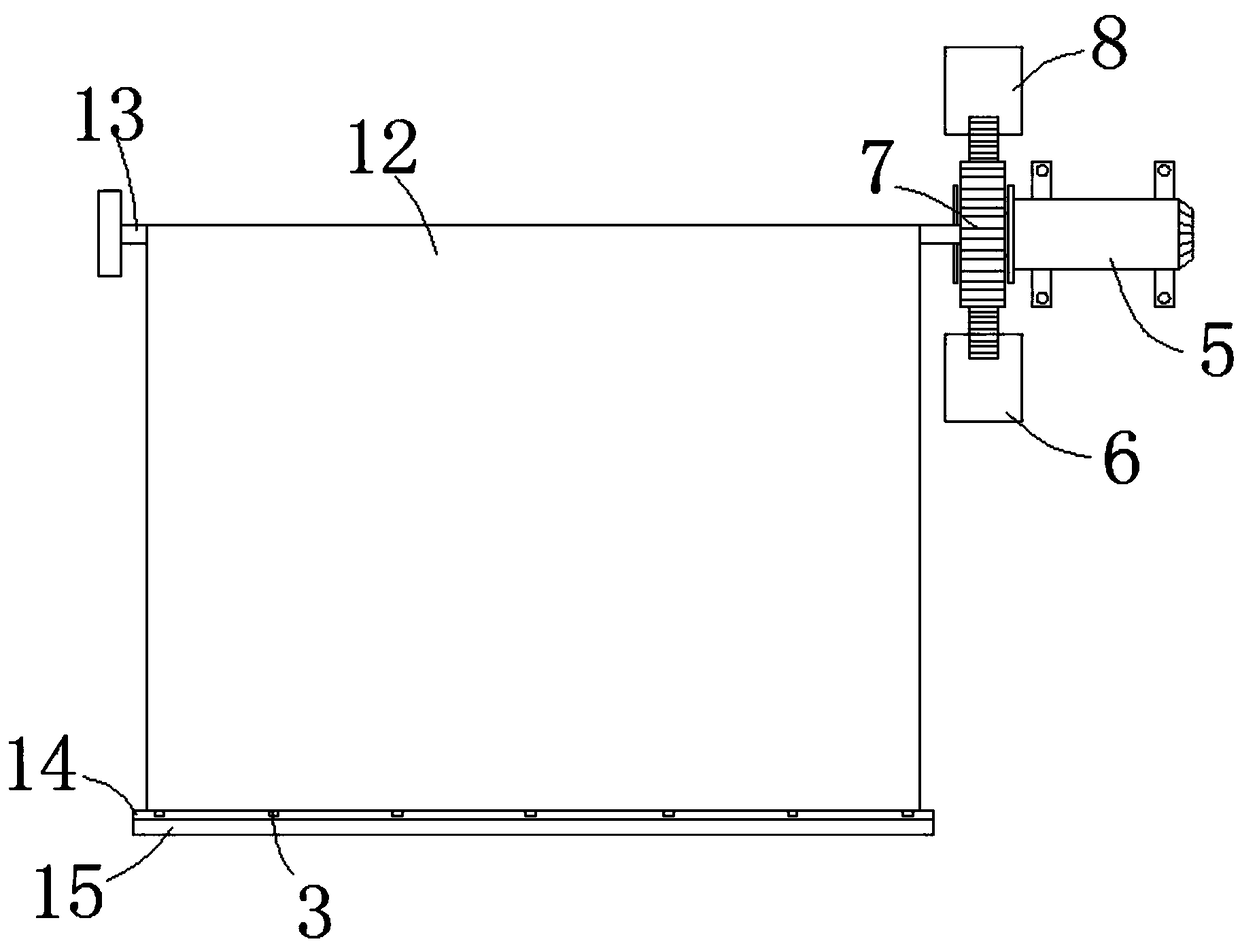

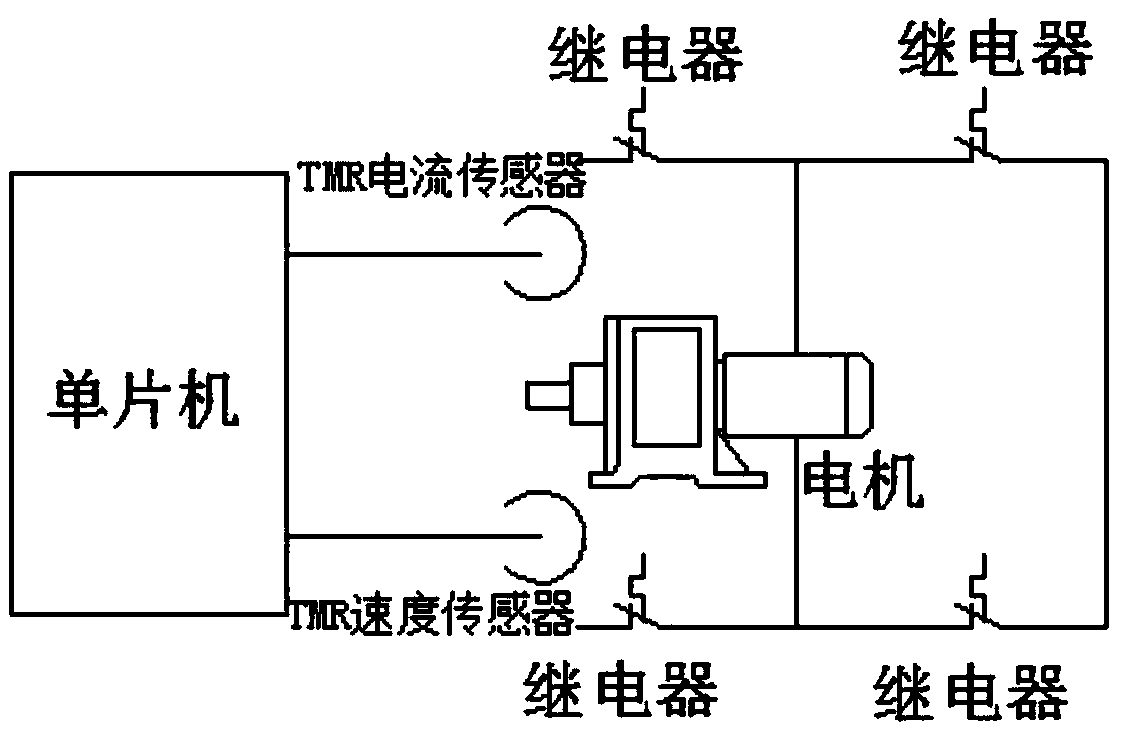

[0026] see Figure 1-5 , the present embodiment provides a TMR magnetoresistive sensor anti-pinch mechanism, including an anti-pinch system 1, and the anti-pinch system 1 includes an isolation shaping circuit 11, a display circuit 10, an alarm circuit 9 and a single-chip microcomputer 2, and the signal input port of the single-chip microcomputer 2 is connected with TMR rotational speed sensor 8, TMR current sensor 6 and infrared scanning sensor 3, the signal output port of single-chip microcomputer 2 is connected with relay 4, and the signal output port of relay 4 is connected with motor 5, and motor 5 includes rotor 7, and motor 5 passes mounting plate Fixed on the top side wall of the door frame, the motor 5 is connected with a rotating roller 13, and the other end of the rotating roller 13 is rotatably connected with the top side wall of the door frame, and the anti-theft rolling door 12 is wound around the rotating roller 13, and the bottom surface of the anti-theft rolling...

Embodiment 2

[0034] see Figure 1-5 , made further improvements on the basis of Embodiment 1: the anti-pinch system 1 is connected to an external power supply through a wire, and the entire circuit is connected to electricity through an external power supply, the motor 5 is a servo motor, and the TMR speed sensor 8 and the TMR current sensor 6 are respectively located at The upper and lower sides of the rotor 7 are arranged in this way to facilitate induction detection of the rotational speed and current of the motor 5. The TMR rotational speed sensor 8 and the TMR current sensor 6 are respectively located on the upper and lower sides of the rotor 7. Several infrared scanning sensors 3 are located at a distance from the front end of the anti-theft rolling door 12. The distance between the planes is 1.5cm, and the purpose of this is to make several infrared scanning sensors 3 not be affected by the anti-theft rolling door 12 in the process of scanning, that is to say, when in the anti-pinch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com