A cam type glass lifter

A glass lifter and cam type technology, which is applied in the field of auto parts, can solve the problems of poor motion stability, glass lifting tilt, sticking, etc., and achieve the effects of increasing sensitivity, improving motion stability, and relative position stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The present invention is further detailed in connection with the embodiments in the accompanying drawings, but will not be construed as limiting the invention.

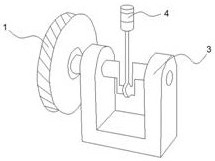

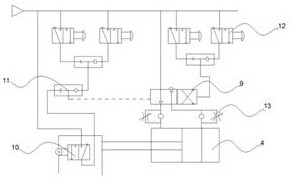

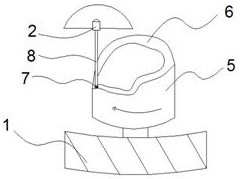

[0019]SeeFigure 1 to 4As shown, a cam type glass lift includes a power gear 1, a glass clip 2, and a piston rod of the cylinder 4 is connected by a crankshaft linkage structure 3 by a crankshaft linkage structure 3, and a cam device 5 is fixed. As the power gear 1 rotates; the cam device 5 is a cylindrical rod body, and a curved groove 6 is formed over the cylindrical rod body or a member of curve groove 6 above the cylindrical rod; the glass clamp 2 is fixed by the link 8 In the roller 7 embedded in the curve groove 6, the roller 7 rolls within the curve groove 6; the curve groove 6 is arranged in accordance with the centerline symmetry of the cylindrical rod, and the vertical height of the curve groove 6 is in accordance with clockwise. The random variable function is distributed on the cylindrical lear; the cylinder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com