An Explosion-proof Centrifuge Conducive to Improving Work Safety

A safe and explosion-proof technology, applied in the centrifugal field, can solve problems such as potential safety hazards, no explosion-proof treatment of electrical components, and manual operation of opening and closing the safety cover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

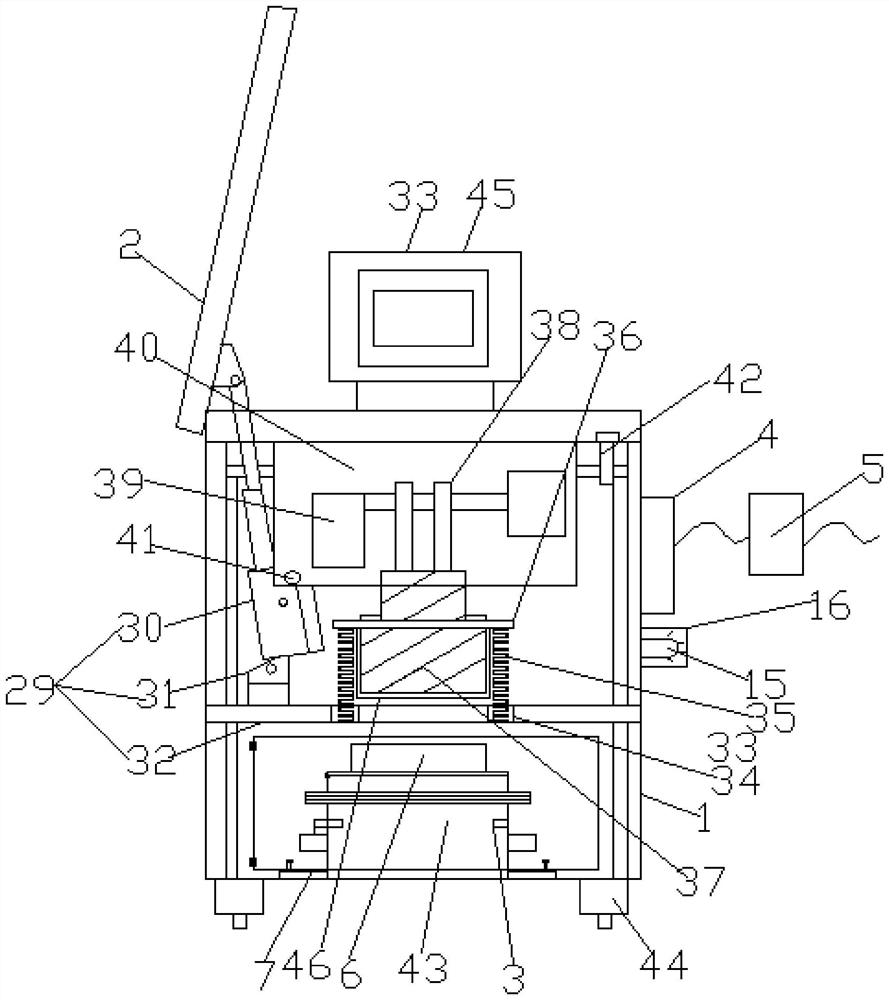

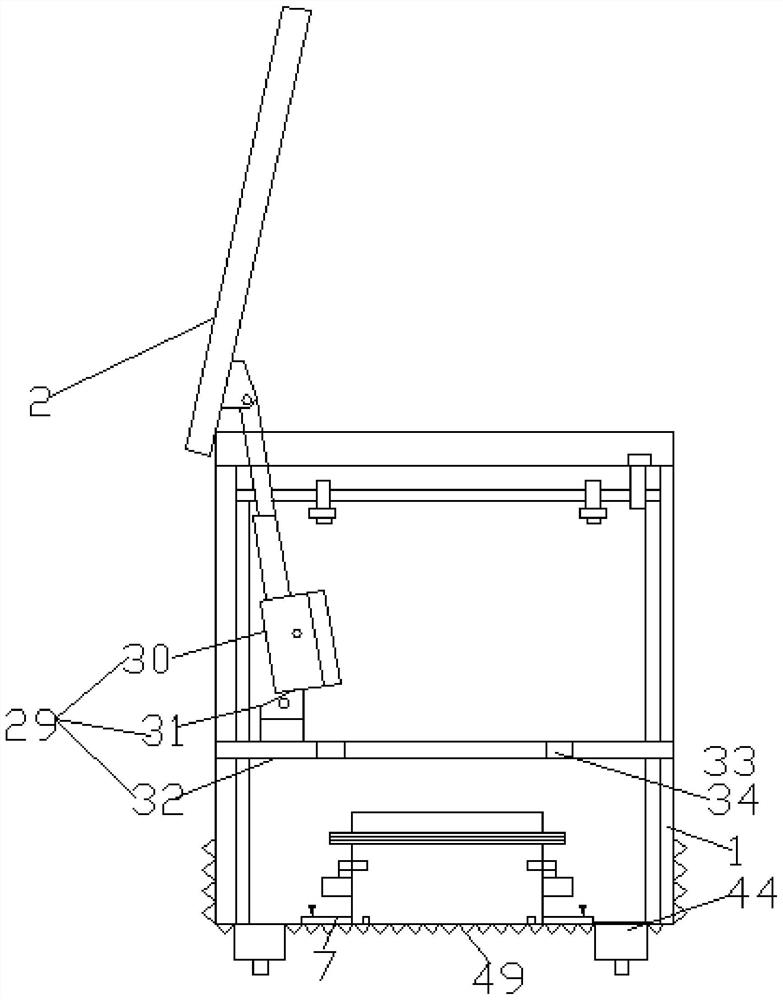

[0031] see Figure 1-6 , according to an embodiment of the present invention, an explosion-proof centrifuge that is conducive to improving work safety includes a sheet metal casing 1 and a box cover 2, and an upper cover is provided between the sheet metal casing 1 and the box cover 2 Drive module 29, the upper cover drive module 29 includes a potentiometer type electric push rod 30, the box cover 2 and the top side of the sheet metal casing 1 are linked by a link, the potentiometer type electric push rod 30 The output top end of the push rod 30 is hingedly connected with the inner bottom end of the box cover 2 through a movable connection. Frame 32, the bottom of the connecting block 31 forms a hinge connection with the frame 32 through a movable link, and the frame 32 is provided with several spring grooves 34, and springs 35 are fixed in the spring groove 34, so that The top of the spring 35 is fixedly provided with a setting plate 36, and the central position of the botto...

Embodiment 2

[0033] see figure 1 , for the alarm 15, the alarm 15 includes an external protective housing 16 and an alarm device arranged in the protective housing 16.

[0034] Through above-mentioned scheme of the present invention, beneficial effect: the setting of protective case 16 is protected alarm 15, and does not affect the use of alarm 15.

Embodiment 3

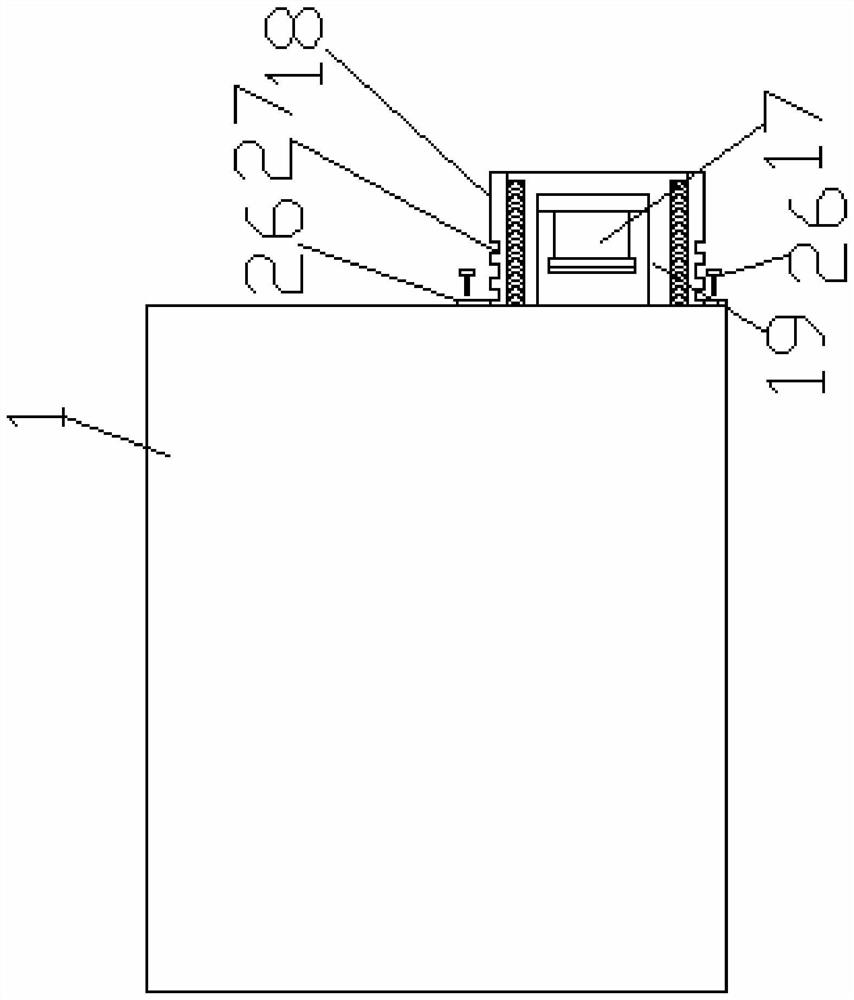

[0036] see Figure 3-4 , for the sheet metal casing 1, the sheet metal casing 1 is provided with an explosion-proof joint 17, and the outer wall of the sheet metal casing 1 is provided with a circular sleeve 18, and the material of the circular sleeve 18 is Sheet metal circular shell, and the interior of the circular sleeve 18 is a cavity structure, the explosion-proof joint 17 is sleeved in the circular sleeve 18, the explosion-proof joint 17 and the circular sleeve A cavity 19 is formed between 18, and the inner wall of the cavity 19 is fixedly pasted with an activated carbon filter screen 20, and the outer wall of the circular sleeve 18 is fixedly provided with a docking cylinder 21, and the explosion-proof joint 17 is connected to a wire joint 22, so The wire joint 22 is connected with a wire 23, and the wire 23 is fixedly sleeved with a secondary docking cylinder 24 that matches the docking cylinder 21, and the secondary docking cylinder 24 is fixedly pasted on one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com