Steel casing, full casing full rotary drilling machine and drilling method for drilling machine

A full-rotary drilling rig and steel casing technology, applied in drilling equipment and methods, drilling equipment, earthwork drilling and production, etc., can solve problems such as casing scrapping and footage speed reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

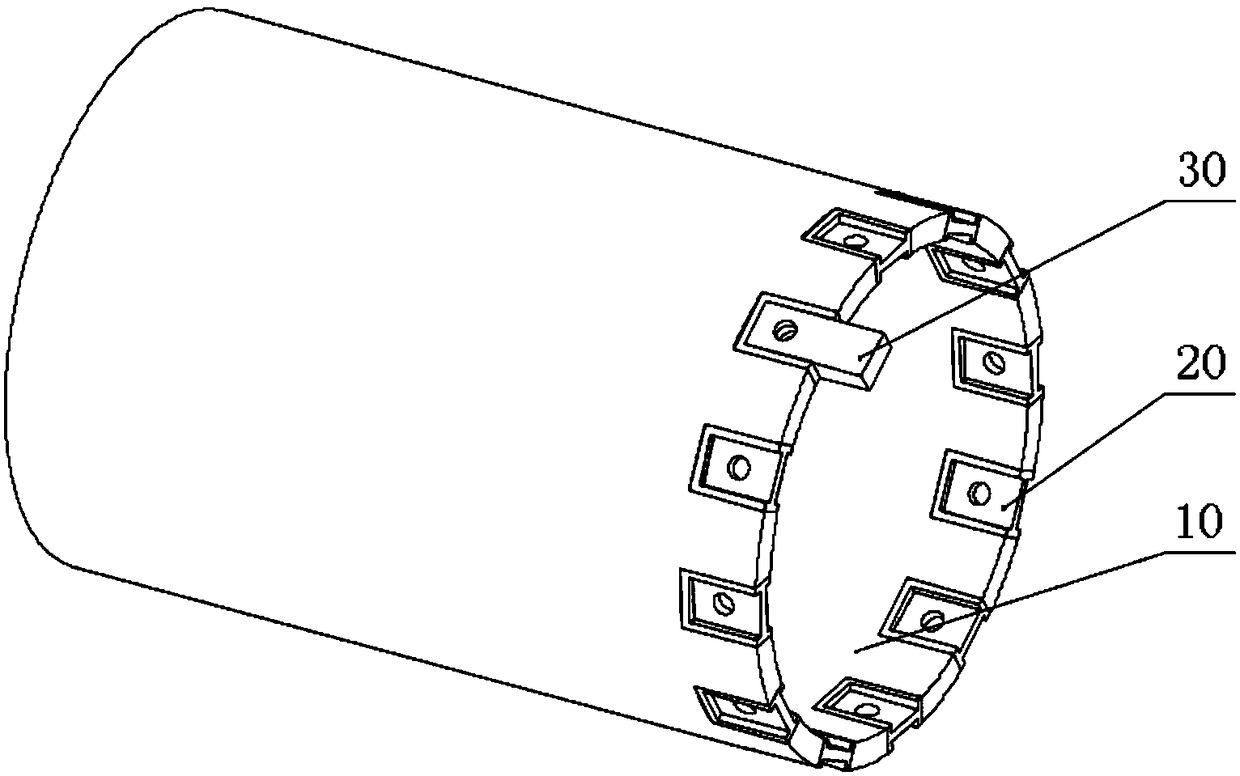

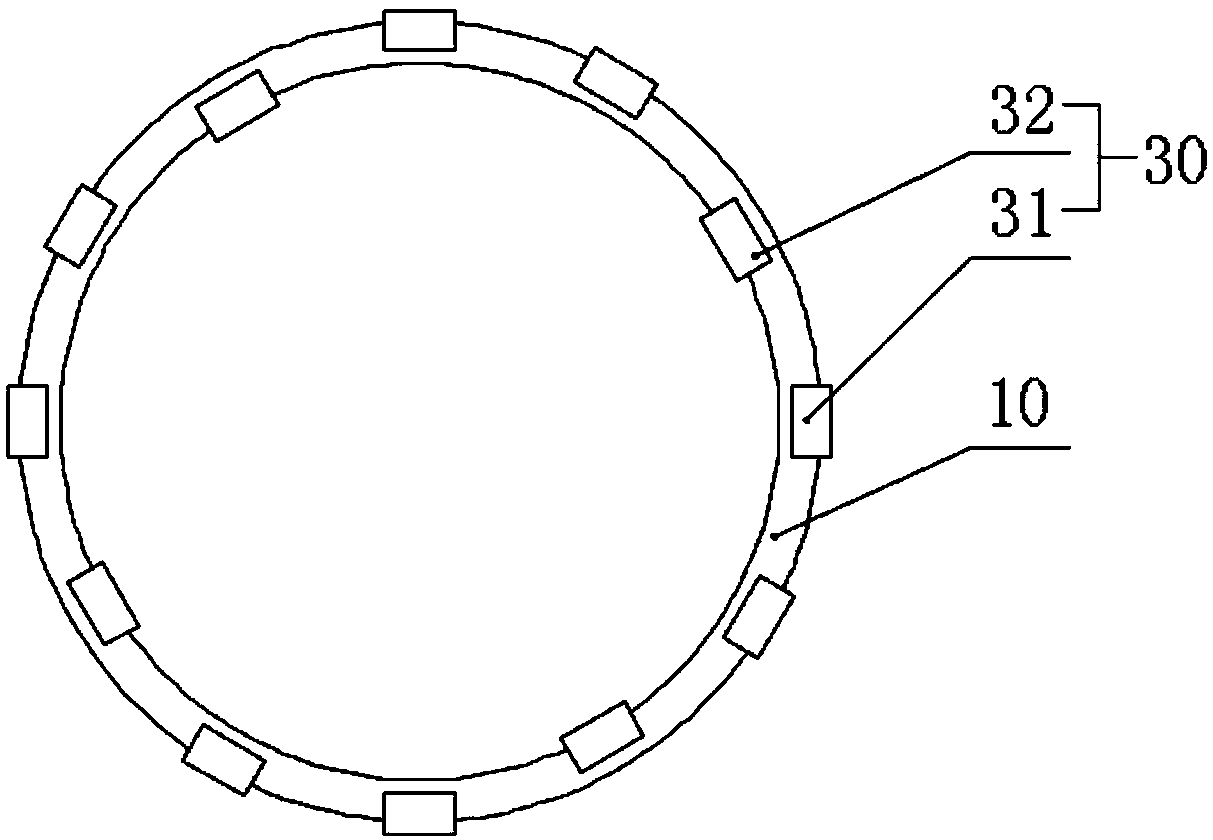

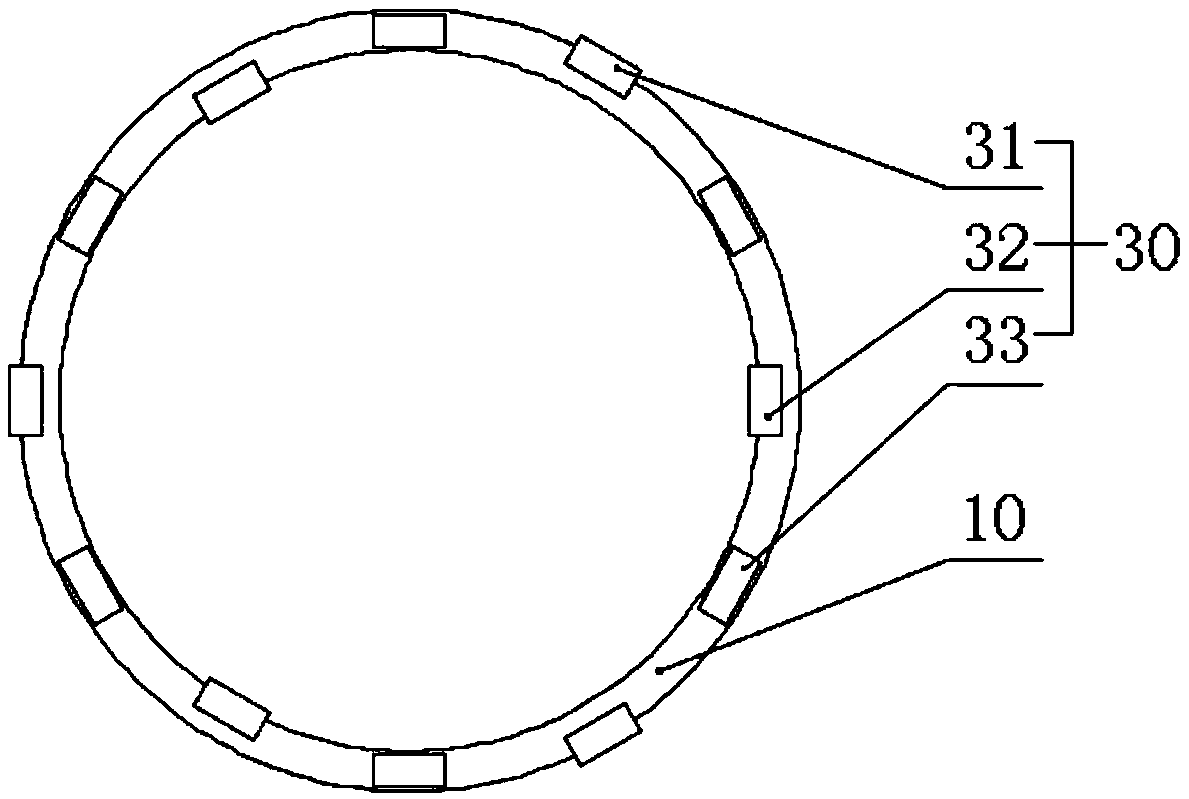

[0024] An embodiment of the present invention provides a steel casing, figure 1 It is a structural schematic diagram of a steel casing provided by an embodiment of the present invention, Figure 4 It is a schematic cross-sectional view of a steel casing provided by an embodiment of the present invention, such as figure 1 and Figure 4 As shown, the steel casing includes a steel casing body 10, a tooth bed 20, a tooth sleeve 30 and fasteners. A plurality of tooth beds 20 are embedded on one end of the steel cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com