Engine oil preheating system, control method thereof and engine

An engine and engine oil technology, which is applied in the direction of machine/engine, engine components, engine lubrication, etc., can solve the problems of poor oil preheating effect, increased fuel consumption and emission, and difficulty in achieving energy saving and emission reduction. The effect of low volume and low starting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

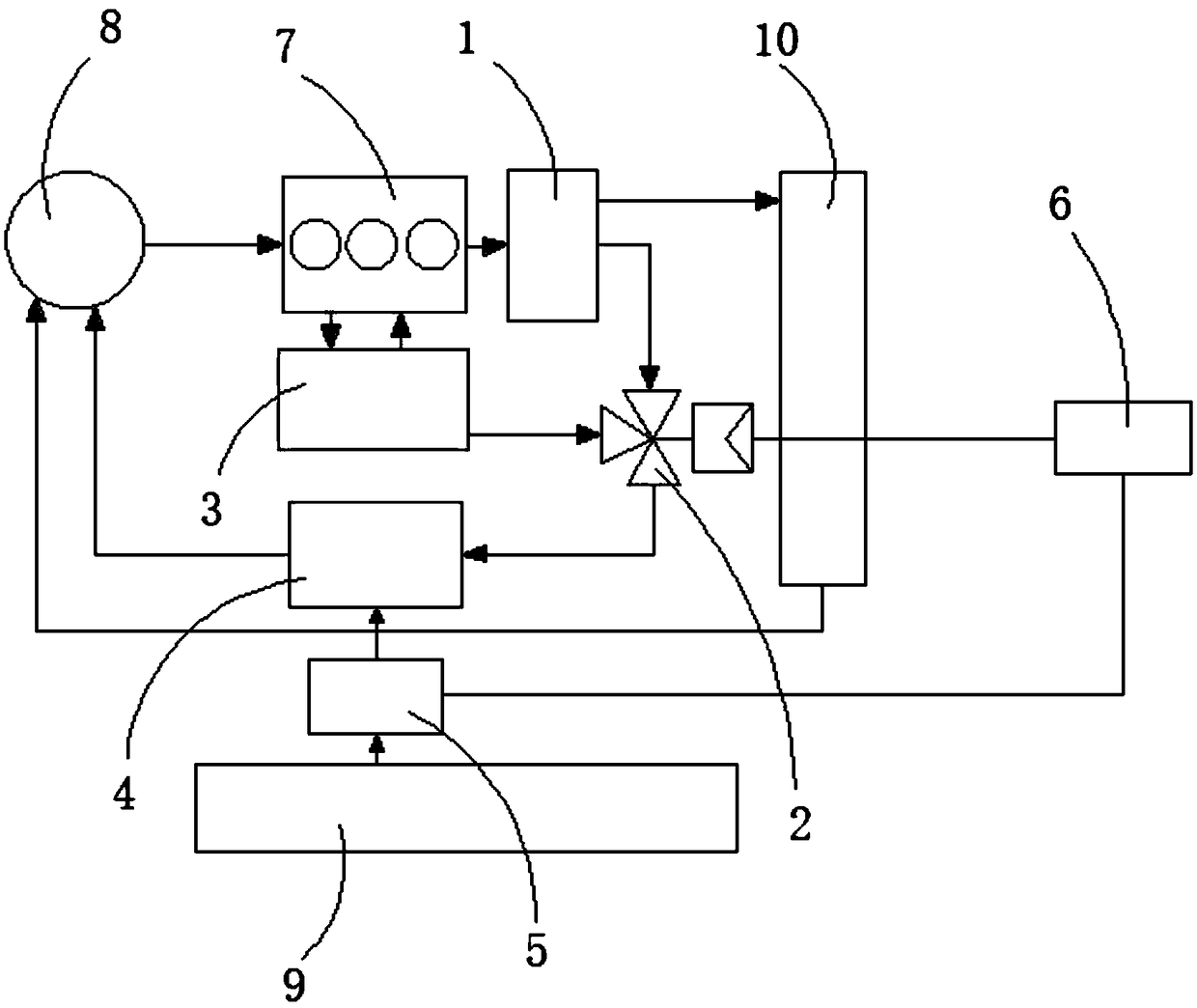

[0031] see figure 1 The first embodiment provides an oil preheating system, including a thermostat 1 , a three-way solenoid valve 2 , a hot water supply device, an oil cooler 4 , an oil temperature sensor 5 and a controller 6 .

[0032] Wherein, the two water inlet ends of the three-way solenoid valve 2 are respectively connected with the water outlet end of the thermostat 1 and the hot water supply device, and the water outlet end of the three-way solenoid valve 2 is connected with the oil cooler. 4 connected.

[0033] The engine oil temperature sensor 5 is used to sense the engine oil temperature, and the engine oil temperature sensor 5 is electrically connected to the controller 6 , and the controller 6 is also electrically connected to the three-way solenoid valve 2 .

[0034] In the engine oil preheating system provided in Embodiment 1, after the engine is started, the engine oil temperature sensor 5 can sense the temperature of the engine oil in the engine, and can tran...

Embodiment 2

[0047] see figure 1 , the second embodiment provides a method for controlling the engine oil preheating system in the first embodiment above, including the following steps:

[0048] The oil temperature sensor 5 senses the temperature of the oil in the engine, and transmits the sensed oil temperature value to the controller 6 .

[0049] The controller 6 analyzes the received oil temperature value, if the oil temperature value is lower than the preset value, the controller 6 sends an opening command to the three-way solenoid valve 2, and the three-way solenoid valve 2 closes Open the passage with the hot water supply device after the opening command, and the hot water flowing out from the hot water supply device flows through the three-way solenoid valve 2 to the oil cooler 4 to preheat the oil; if the oil When the temperature is higher than the preset value, the controller 6 sends a closing command to the three-way solenoid valve 2, and the three-way solenoid valve 2 closes th...

Embodiment 3

[0052] Correspondingly, the third embodiment provides an engine, which includes the engine oil preheating system involved in the first embodiment above (the specific structure of the oil preheating system will not be described one by one), and also includes the engine body; The engine oil preheating system is installed on the engine body.

[0053] Obviously, the engine provided by the third embodiment has all the advantages of the oil preheating system in the first embodiment because it includes the oil preheating system in the first embodiment, the starting resistance of the engine is small, and the fuel consumption and emissions are low .

[0054] In summary, the present invention discloses an engine oil preheating system, a control method and an engine, which overcome many technical defects of traditional engines. The engine oil preheating system, control method and engine provided in this embodiment have small starting resistance, low fuel consumption and low emissions wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com