Quick-mounting gate valve of enamel sealing and with high performance

A fast-installation, high-performance technology, applied in shaft seals, sliding valves, valve details, etc., can solve the problems of large opening torque, inconvenient disassembly, easy corrosion, etc., and achieve the effect of small starting load, convenient processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

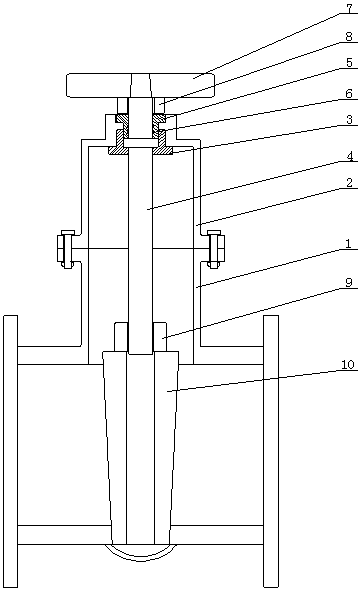

[0022] as attached figure 1 to attach image 3 Shown:

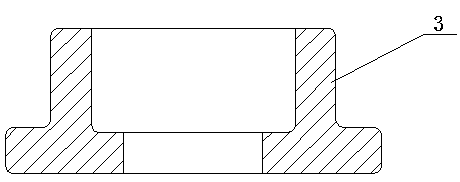

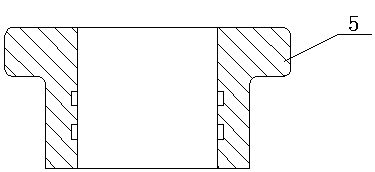

[0023] The invention provides a high-performance enamel-sealed quick-installation gate valve, which includes a valve body 1, a valve cover 2, a copper nut 3, a valve stem 4, a lock nut 5, an O-ring 6, a hand wheel 7, a pressure sleeve 8, Connecting nut 9, gate plate 10, the inner surface of the valve body 1 is coated with inorganic glass enamel, the top of the valve body 1 is fixedly connected with the valve cover 2, and the inner top wall of the valve cover 2 is screwed into the There is a copper nut 3, the top of the valve cover 2 and the inside of the copper nut 3 are movably inserted with a valve stem 4 extending to the inside of the valve body 1, and the inside of the copper nut 3 and the outside of the valve stem 4 are threaded into Connected with a lock nut 5, the inside of the lock nut 5 and the outer side of the valve stem 4 are fixedly sleeved with an O-ring 6, and the top of the valve stem 4 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com