Double-flow microchannel evaporator with double liquid supply tubes and gas guide thin tube

A micro-channel and evaporator technology, applied in evaporator/condenser, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of uneven liquid supply, large gas volume, and reducing the effective heat exchange area of the second process , to improve the uniformity of the liquid supply, ensure the heat exchange performance, and improve the flow rate and flow of the refrigerant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

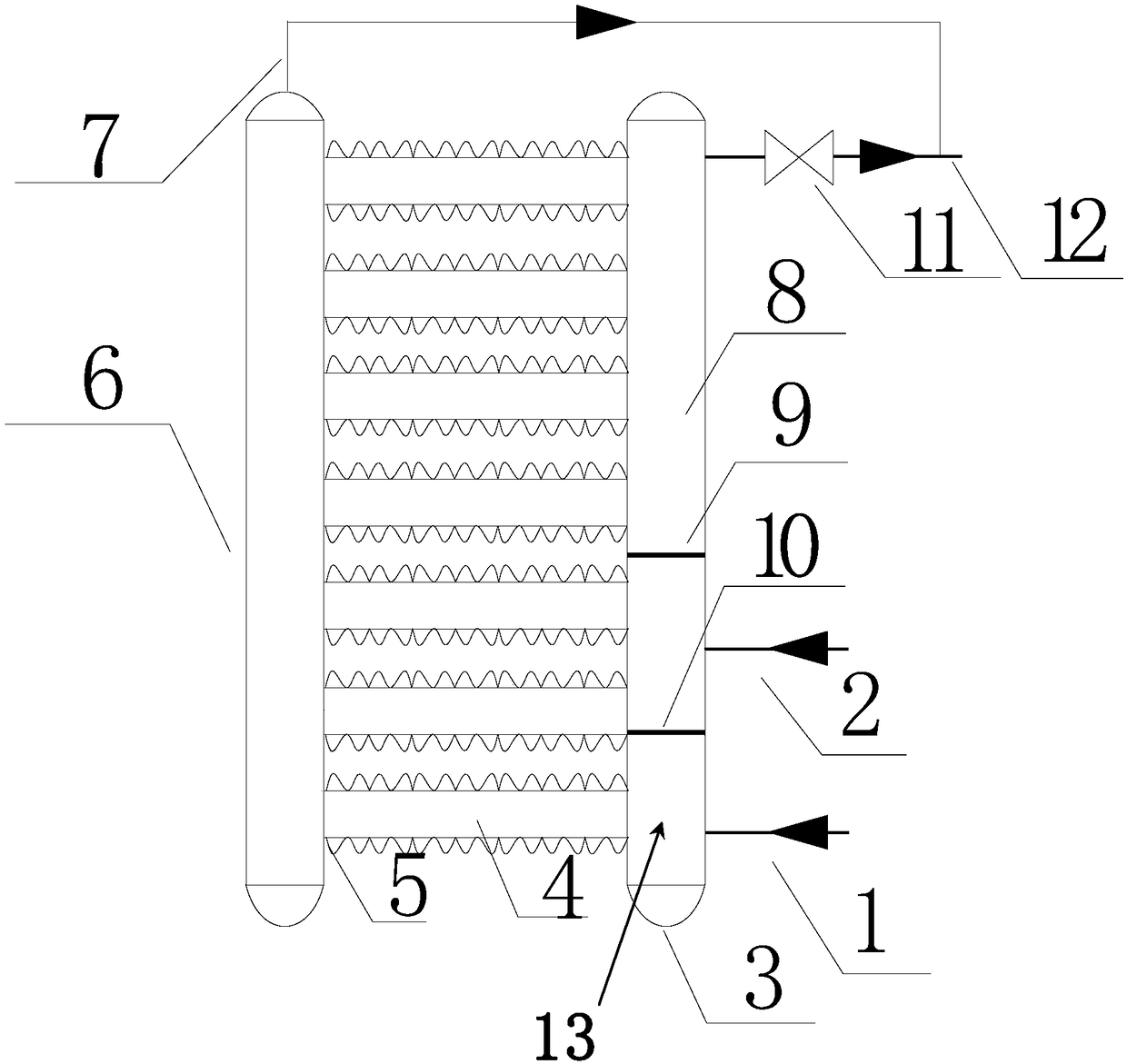

[0029] see figure 1 , the present invention provides a double-flow microchannel evaporator with double liquid supply pipes and thin gas guide pipes, including a hollow confluence header 6 and a main header 13 arranged at intervals on the left and right;

[0030] The opposite sides of the converging header 6 and the main header 13 are connected through a plurality of horizontally distributed flat tubes 4;

[0031] The main header 13 is provided with a split-range baffle 9 distributed laterally, and the split-range baffle 9 divides the main header 13 into two cavities of the inlet header 3 and the outlet header 8, and the inlet The header 3 is located below the outlet header 8;

[0032] It should be noted that the inlet header 3 and the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com