Bearing fault diagnosis method based on knn-adaboost

A fault diagnosis and bearing technology, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems such as accurate diagnosis of bearing faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

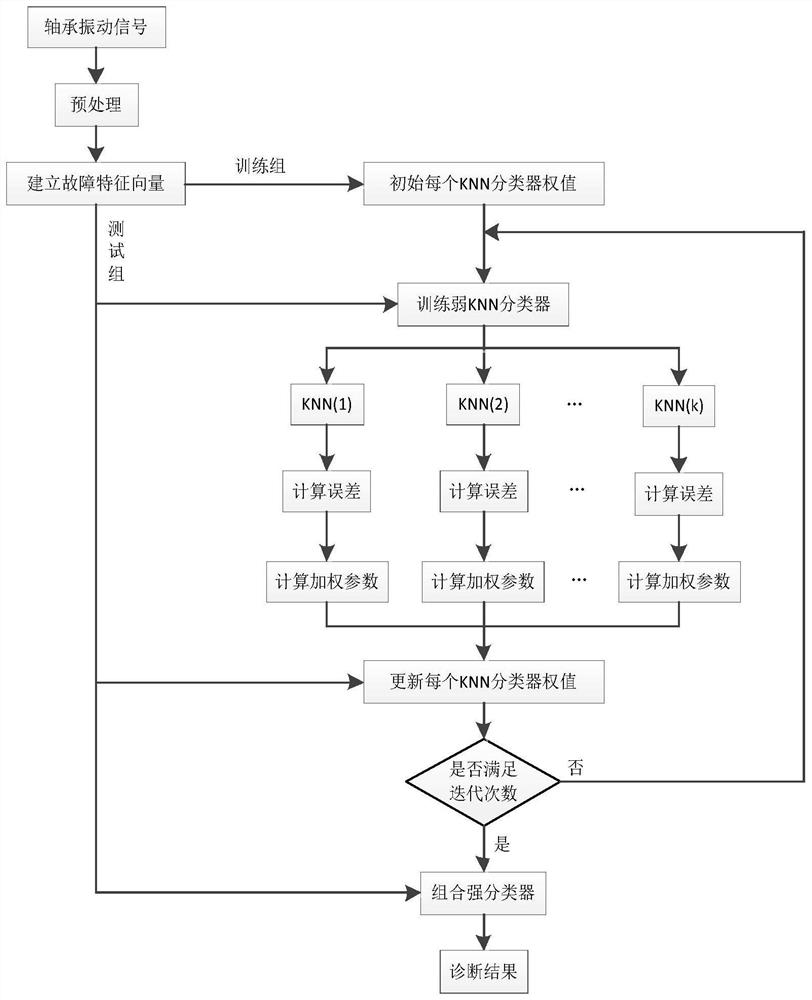

[0075] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0076] The bearing fault diagnosis method based on KNN-AdaBoost is carried out according to the following steps:

[0077] Step 1, obtain the multi-segment vibration signals of the shearer bearing in different states, and use all the vibration signals in each segment of the vibration signal as a set of vibration signals;

[0078] Step 2, each vibration signal in each group of vibration signals is preprocessed into a modal component for determining the center frequency and bandwidth, and multiple groups of modal components for determining the center frequency and bandwidth are obtained;

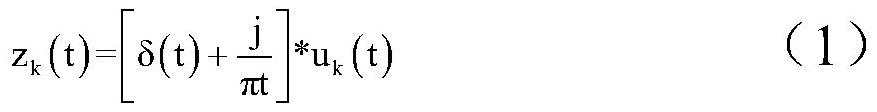

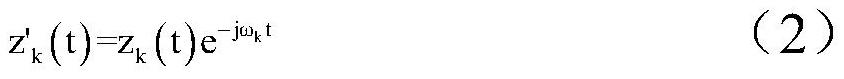

[0079] In step 2, preprocess each vibration signal into a modal component that determines the center frequency and bandwidth according to the following steps:

[0080] Step 2.1, establish a constrained variational model for each vibration signal, specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com