An analysis method for the correlation between engine vibration and casing components

An analysis method and engine technology, applied in the direction of engine testing, machine/structural component testing, instruments, etc., can solve the problem of many human factors, weak pertinence, and inability to accurately describe the size of casing components. Internal relationship and other issues, to achieve the effect of improving assembly quality, reducing renovation costs, and accurate indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

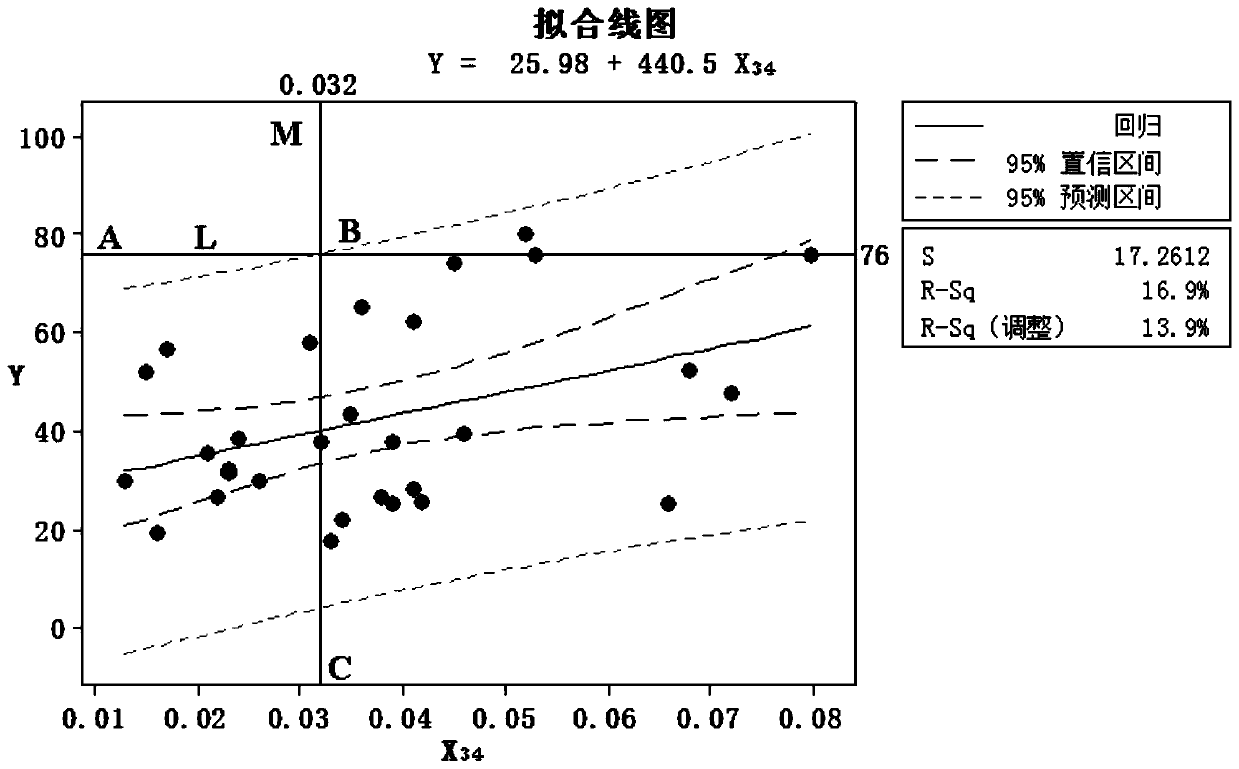

[0027] In this embodiment, the steps of the analysis method for the correlation between the vibration of the rear fulcrum of the Qinling aero-engine in the heated state and the casing components are as follows:

[0028] (1) Determine the analysis target (that is, determine the research direction): According to the vibration failure mode of Qinling aero-engine test run during the renovation period, determine the analysis target, and the analysis target is the vibration of the fulcrum after the heating state;

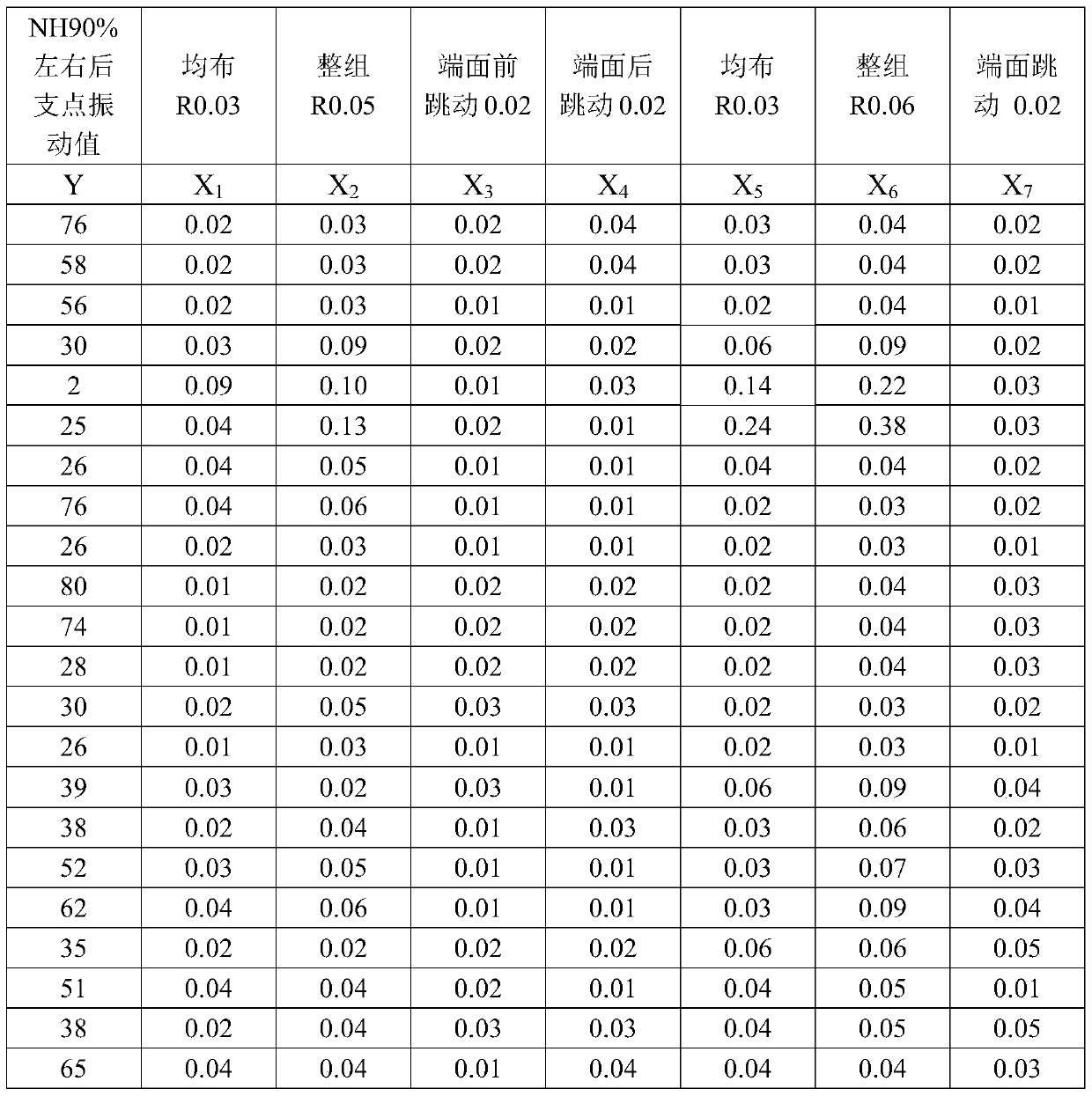

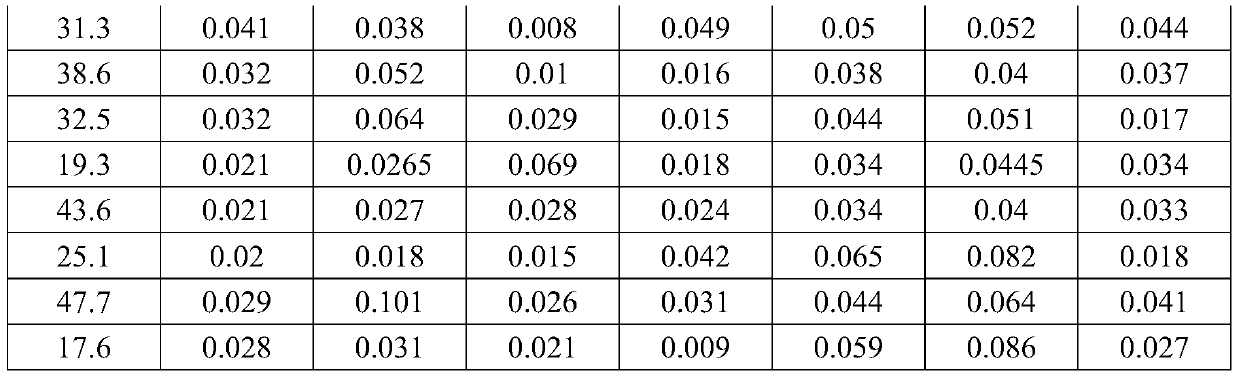

[0029] (2) Failure mechanism analysis: Determine the analysis object and the size of the analysis object according to the design drawing of the Qinling aero-engine casing components and the assembly relationship of the casing components, and use the analysis object and the size of the analysis object as the influencing factors; the analysis object Try to consider comprehensively, such as the runout of the end surface of the bearing seat and the displacement of the supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com