A trash rack experimental platform based on the formation of a free liquid surface in a closed water tank with a high water level in a short distance

A technology of closed water tank and high-level water tank, which is applied in the field of pump station engineering, can solve the problems of increasing unnecessary expenditure, difficulty in forming free liquid surface, water spilling, etc., and achieves simple and easy installation process, reduced renovation costs, and reduced workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and description of drawings, the present invention will be further described:

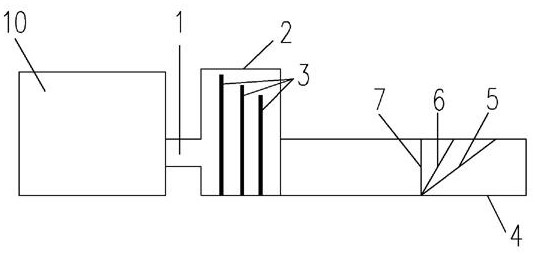

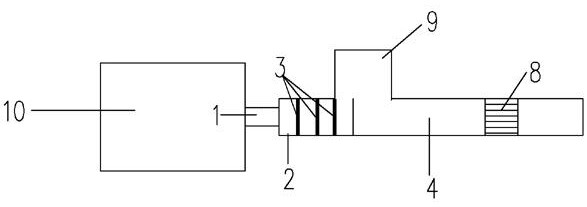

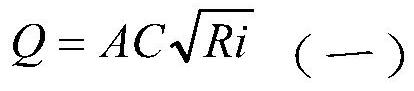

[0034] Based on the trash rack test bench that forms a free liquid surface in the close range of the high water level closed water tank, it consists of the water inlet pipe 1, the closed transparent diversion high level water tank 2, the diverter plate 3, the transparent main body experimental flow channel water tank 4, and simulates long-distance irregularities The dirt movement water tank 9, the trash rack 8 and the trash rack 30° draw-in groove 5, the trash rack 60° draw-in slot 6, and the trash rack 90° draw-in slot 7 form. The trash rack 8 and the trash rack 30° slot 5, the trash rack 60 ° slot 6, and the trash rack 90 ° slot 7 are set and installed in the transparent main body experimental flow channel water tank 4, and the transparent main body experimental flow channel water tank 4 It is mainly made of transparent plexiglass, and its mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com