Heat treatment method for long material, manufacturing method for long material, and heat treatment furnace used in above methods

A heat treatment method and heat treatment furnace technology, applied in heat treatment furnaces, heat treatment process control, heat treatment equipment, etc., can solve problems such as difficult to uniformly heat treated products, quality defects, unsatisfactory methods for uniform treatment temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

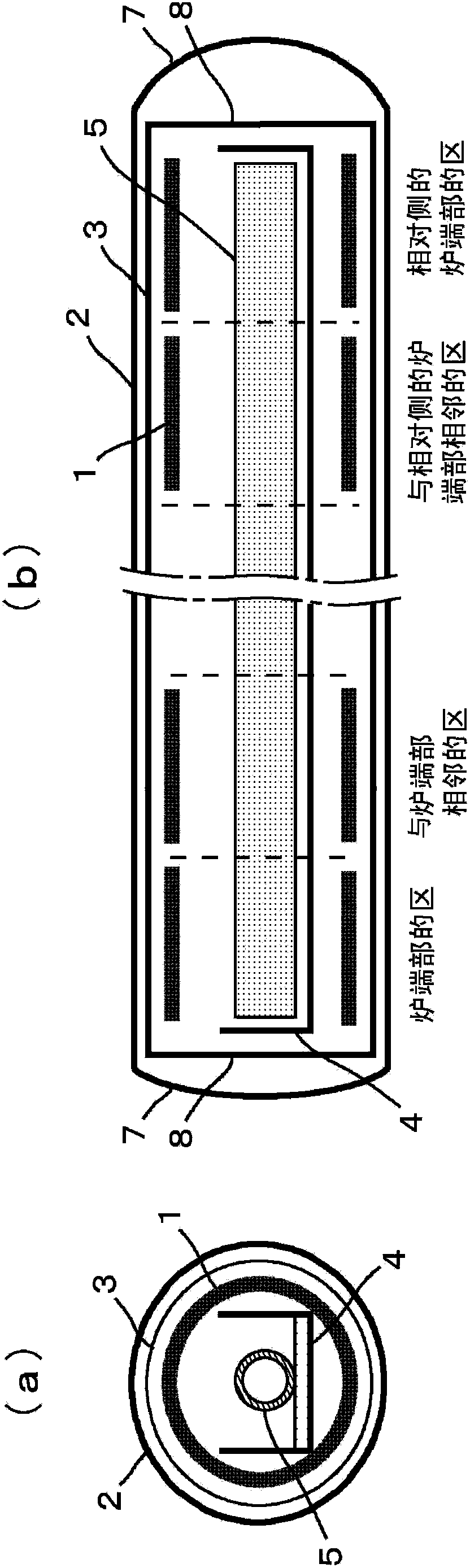

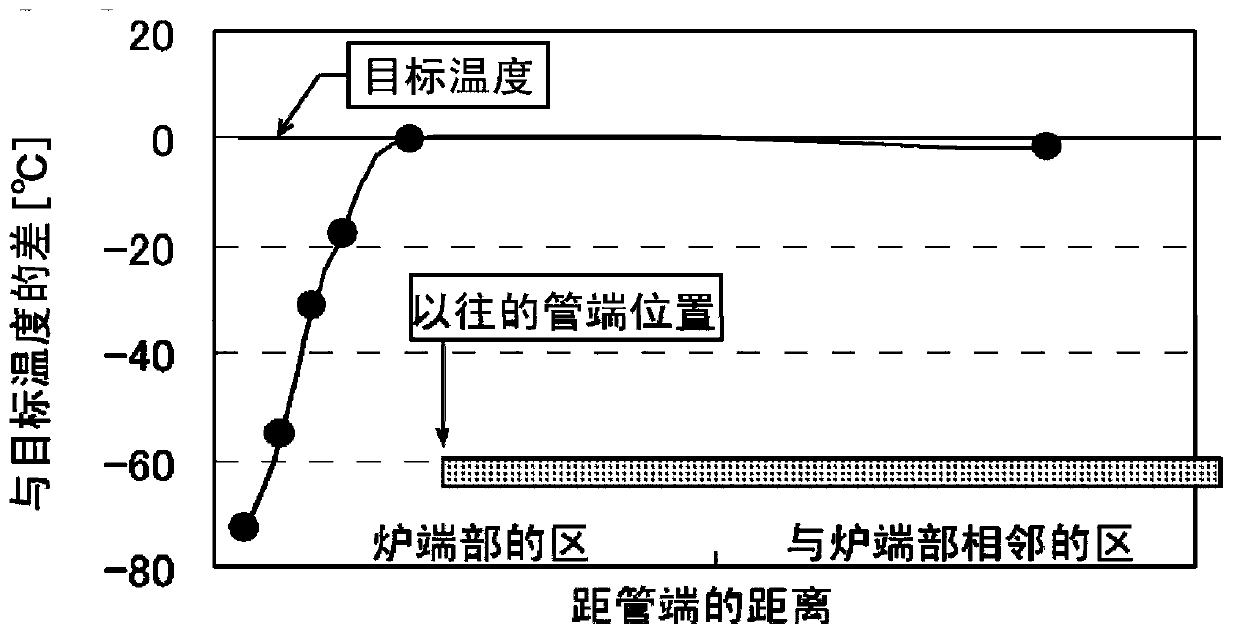

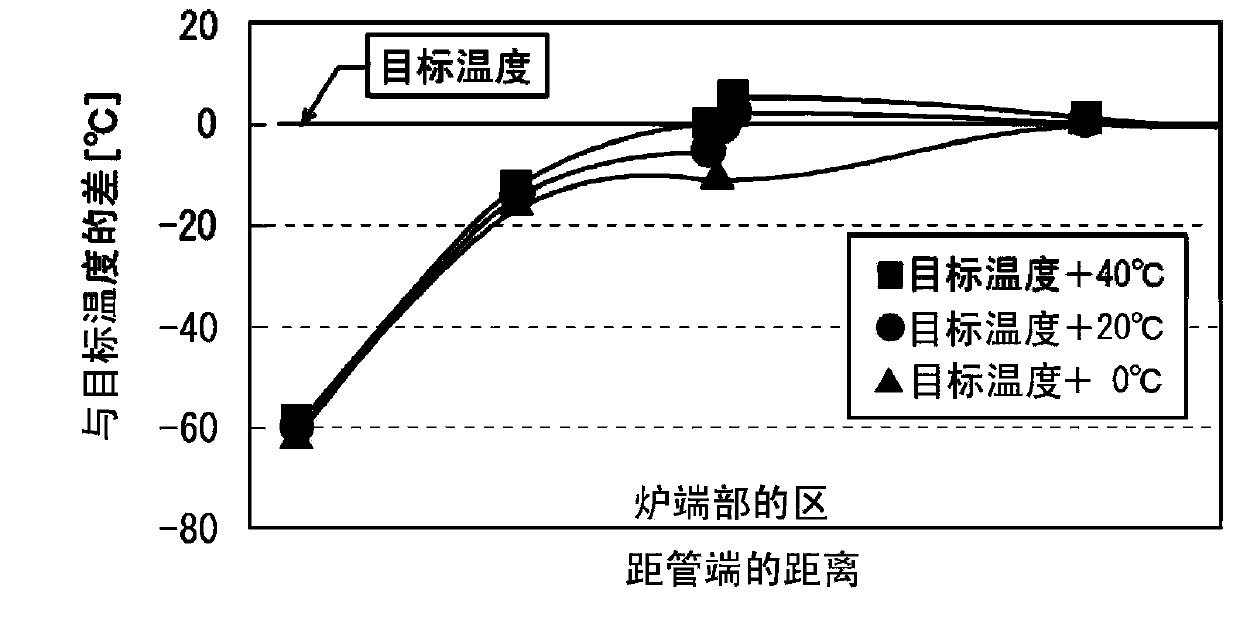

[0130] Use the aforementioned Figure 8 In the heat treatment furnace of the present invention having the configuration shown, a metal pipe was placed in the furnace as a long material to be heat treated (long material), and the temperature distribution at the end of the material to be heat treated when heating was performed by applying the heat treatment method of the present invention was investigated. . For comparison, the same investigation was performed on the case where the conventional heat treatment method was applied.

[0131] The inside of the heat treatment furnace used was divided into a plurality of heating zones from zone m to zone n, and the length of each heating zone was 3 m. Among them, the m-region at the end of one side is sequentially divided into three regions from the top into m-1 region, m-2 region and m-3 region; Divide into n-1 area, n-2 area and n-3 area. The divided lengths of the respective heating zones constituting the m-zone and n-zone at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com