An online detection device for nuclear power plant fuel assembly damage

A fuel assembly and detection device technology, which is applied in the field of nuclear power, can solve the problems of fuel assembly damage, large influence of data environmental factors, and easy leakage of gas sample radioactivity level, so as to achieve accurate damage judgment, improve detection lower limit, and reduce background horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

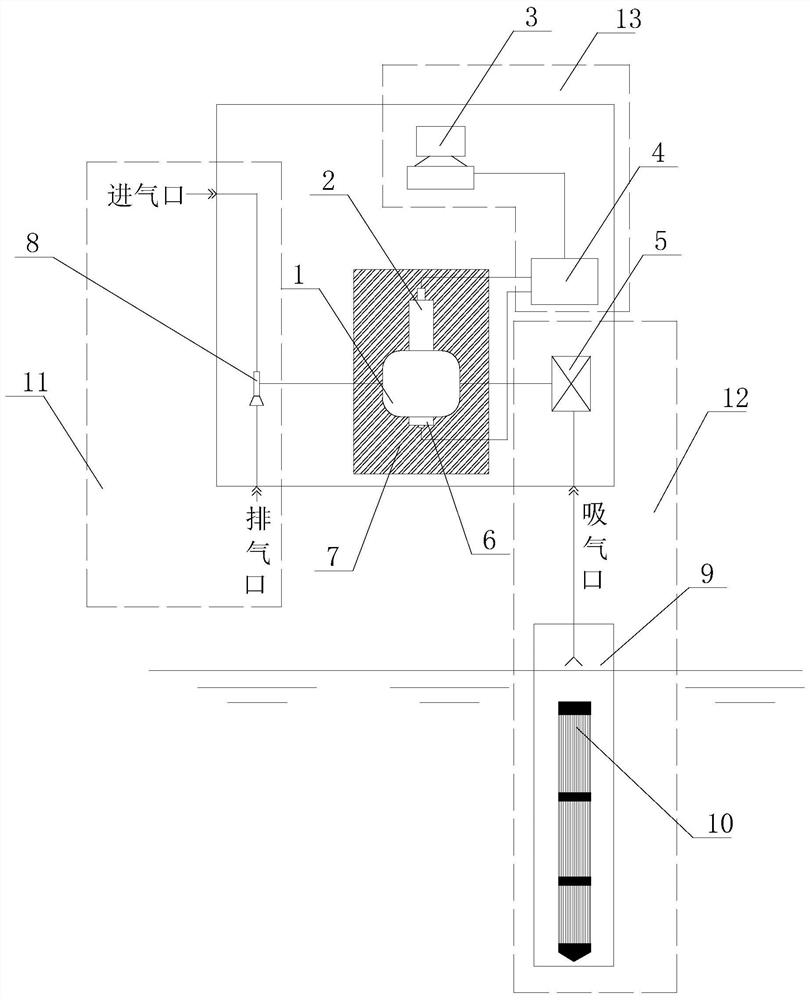

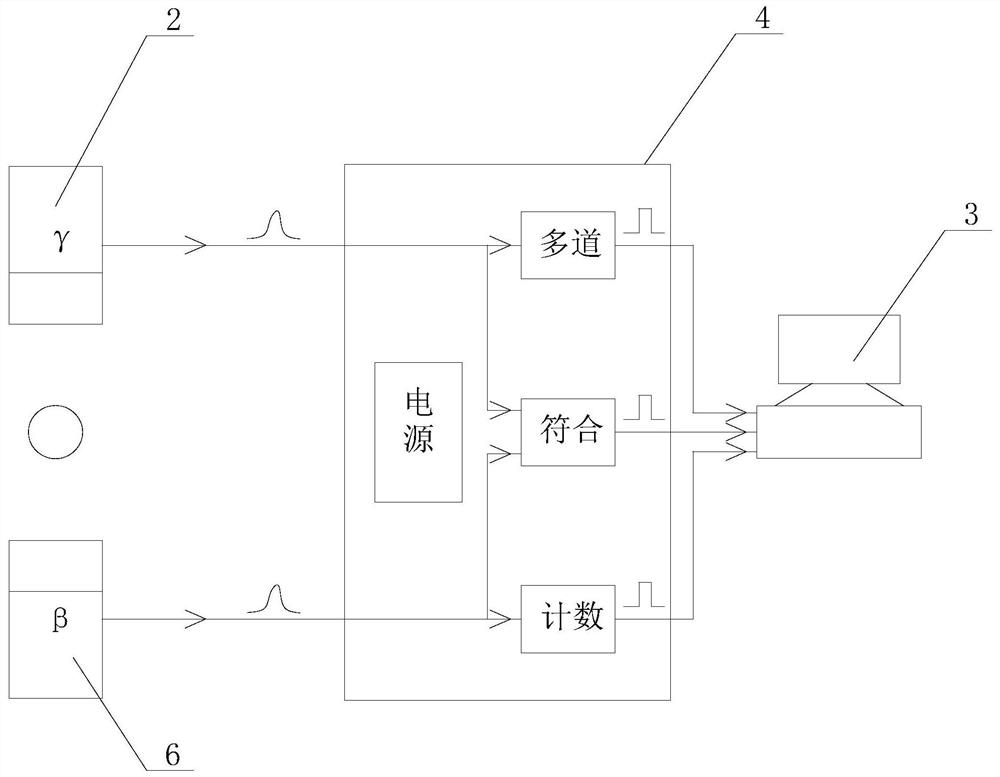

[0027] Such as figure 1 As shown, an on-line detection device for nuclear power plant fuel assembly damage of the present invention includes a gas sampling chamber 1, a gamma radiation detector 2, a beta radiation detector 3, an air extraction device 11, an air suction device 12 and a nuclear data processing device 13; The gamma radiation detector 2 and the beta radiation detector 3 are arranged on the gas sampling chamber 1, and the gamma radiation detector 2 detects the gamma ray particles in the gas sampling chamber 1, and the beta radiation detector 3 detects the beta radiation particles in the gas sampling chamber 1 Ray particles; the gamma radiation detector 2 and the beta radiation detector 3 are connected to the nuclear data processing device 13, and the gamma radiation detector 2 and the beta radiation detector 3 send the collected data to the nuclear data processing device 13; the The air extraction device 11 is communicated with the gas sampling chamber 1, and the a...

Embodiment 2

[0030] In this embodiment, on the basis of Embodiment 1, the air extraction device 11 includes an air inlet, a negative pressure generating unit 8 and an exhaust port connected in sequence, and the negative pressure generating unit 8 is connected to the gas sampling chamber 1 and is connected to the gas sampling chamber 1. A negative pressure is generated in the sampling chamber 1 .

[0031] During the implementation of this embodiment, the negative pressure generating unit 8 provides negative pressure in the gas sampling chamber 1, and the air suction device 12 sucks the gas of the fuel assembly; Unit 8 is discharged.

Embodiment 3

[0033] In this embodiment, on the basis of Embodiment 1, the suction device 12 includes a gas pretreatment unit 5, a suction port, and a suction sleeve 9 connected in sequence; the suction sleeve 9 collects the gas of the fuel assembly 10 The gas of the fuel assembly 10 is pretreated by the gas pretreatment unit 5 and then enters the gas sampling chamber 1 .

[0034]During the implementation of this embodiment, the gas of the fuel assembly 10 is collected by the sip sleeve 9, and enters the gas pretreatment unit 5 through the suction port, and the gas pretreatment unit 5 performs pretreatment such as drying on the gas and then transports it to the gas sampling chamber 1. Through the cooperation of the aspirating device 12 and the aspirating device 11, the continuous detection of the gas of the fuel assembly 10 is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com