An electric vehicle battery pack constant temperature control system and control method

A technology of constant temperature control and electric vehicles, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problem that the battery pack cannot be controlled independently, and achieve the effect of improving the temperature field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

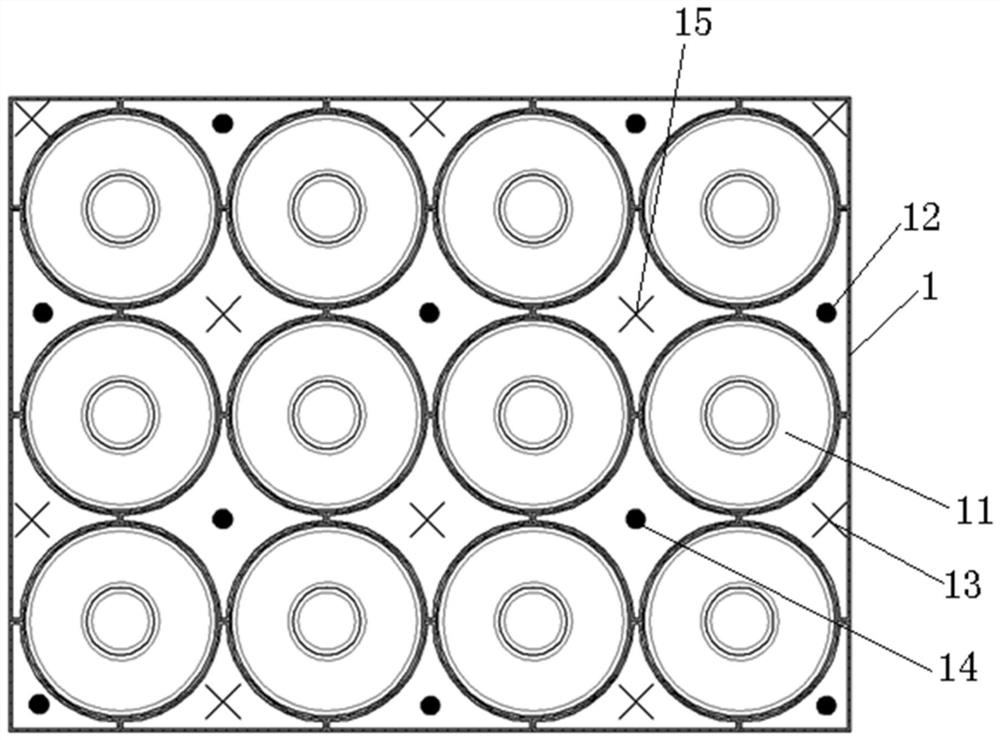

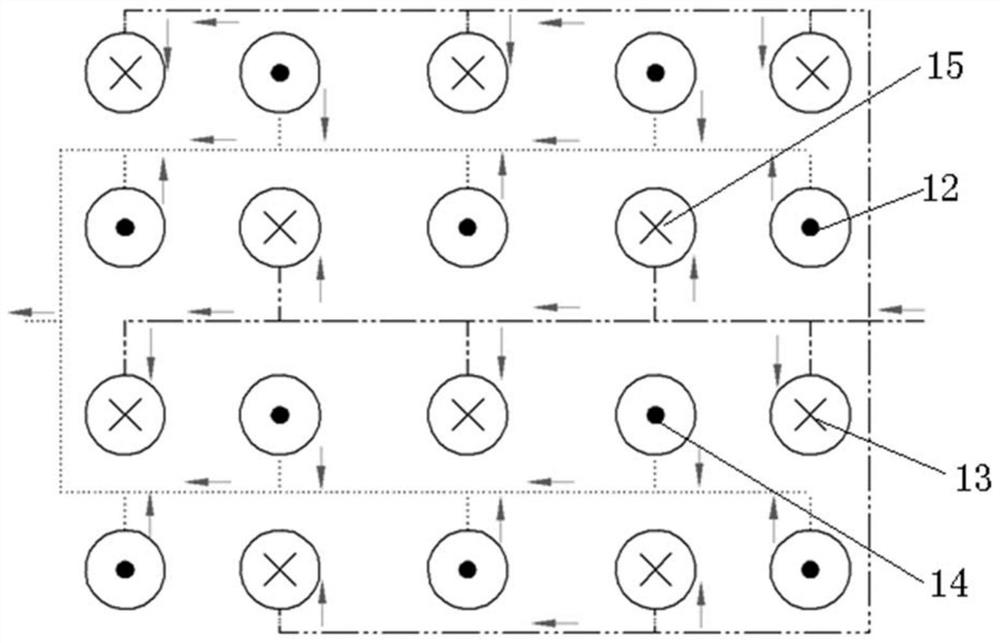

[0039] Such as Figures 2 to 4 As shown, an electric vehicle battery pack constant temperature control system includes a battery pack 1, a battery pack front cooling plate 2, and a battery pack rear cooling plate 3; the battery pack is arranged between the battery pack front cooling plate and the battery pack rear cooling plate between; figure 2 where is the coolant flow path in a certain battery pack, where figure 2 Middle × means that the circulating fluid flow direction in the pipeline is vertically inward, · means that the circulating fluid flow direction in the pipeline is vertically outward.

[0040] Such as Figure 4 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com