Matrix temperature control chip of thermal forming machine

A technology for controlling chips and thermoforming machines, used in temperature control, non-electric variable control, control/regulation systems, etc., can solve the problem of not considering the coupling interference of control points, etc., to improve temperature field distribution, reduce use costs, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

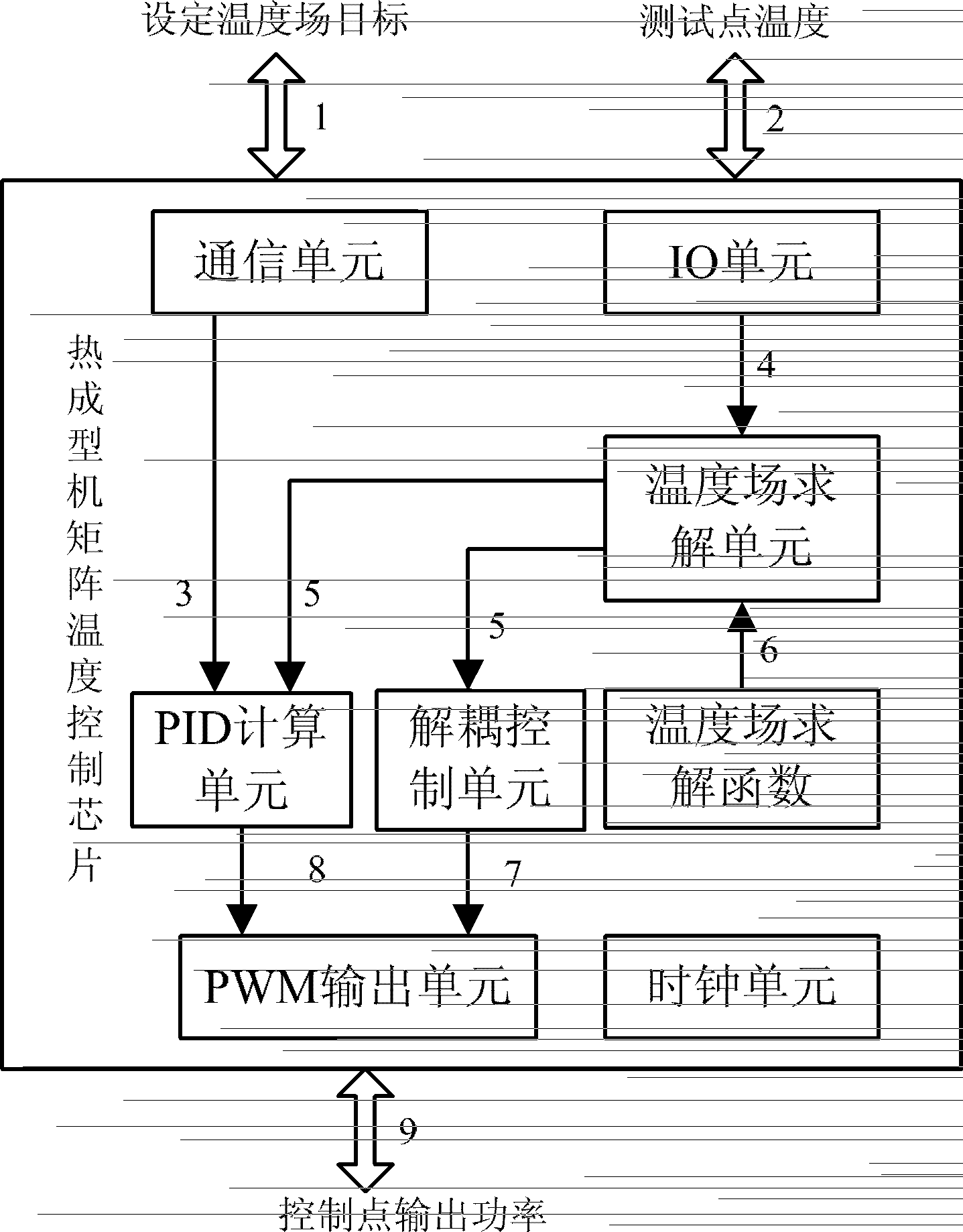

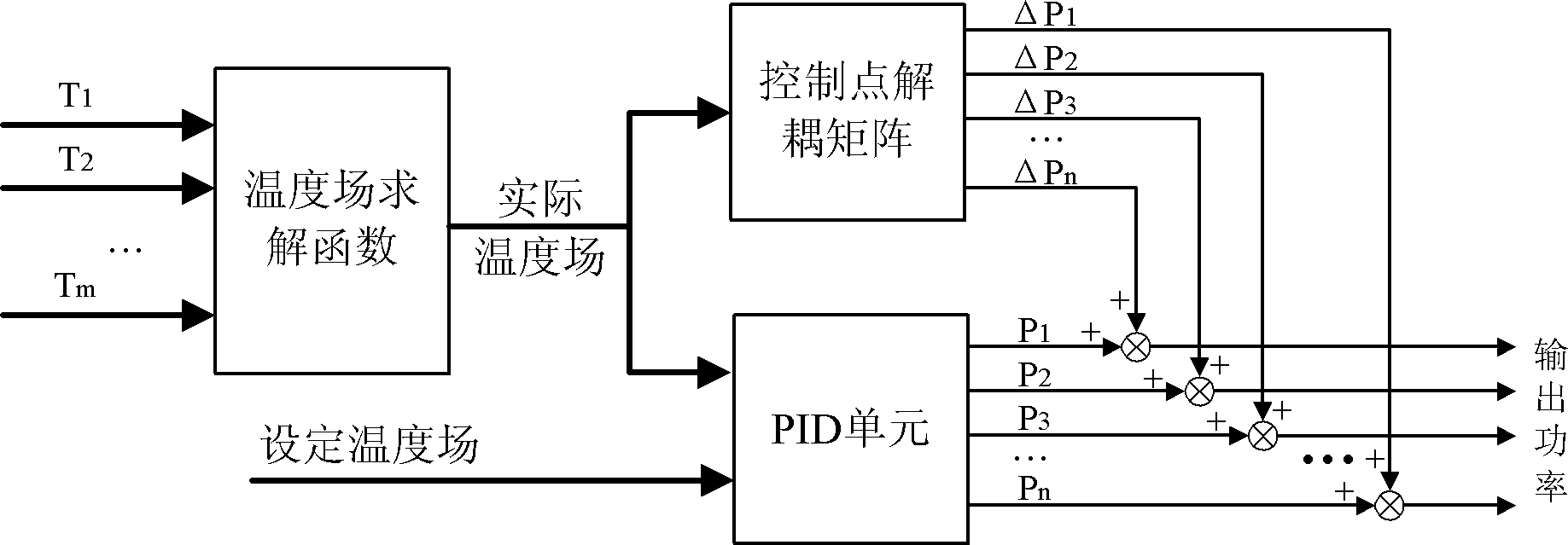

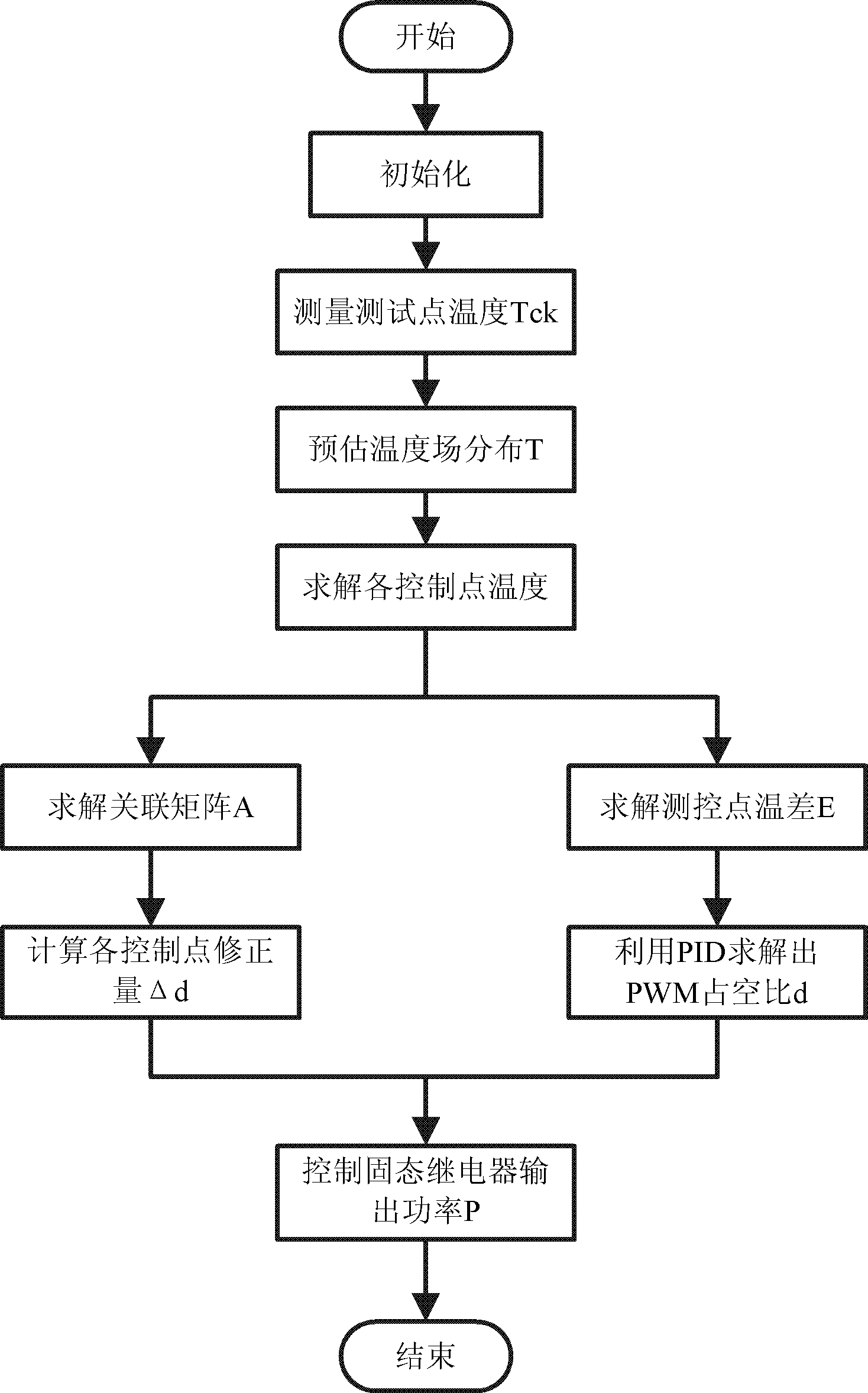

[0013] like figure 1 As shown, the control chip of the present invention is divided into 7 processing units that operate in parallel with each other: IO unit, clock unit, communication unit, temperature field solution unit, matrix decoupling control unit, PID calculation unit, PWM output unit, wherein the communication The unit obtains the temperature field setting target (3) through the peripheral communication interface and transmits it to the PID calculation unit in the chip. The IO unit obtains the temperature value of each test point (4) through the external thermocouple and AD conversion chip and filters it. Transmission to the temperature field solving unit, the temperature field solving unit uses the temperature field solving function to find the distribution of the temperature field in the furnace (5) and the control point decoupling matrix, the PID calculation unit sets the target (3) and the actual temperature field distribution according to the temperature field (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com