Terminal and assembling method thereof

An assembly method and terminal technology, which can be applied to the structure of telephones, telephone communications, instruments, etc., can solve the problems of poor flexibility, inability to flexibly adjust the curvature of the screen, and failure to take into account the bending protection of flexible screens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

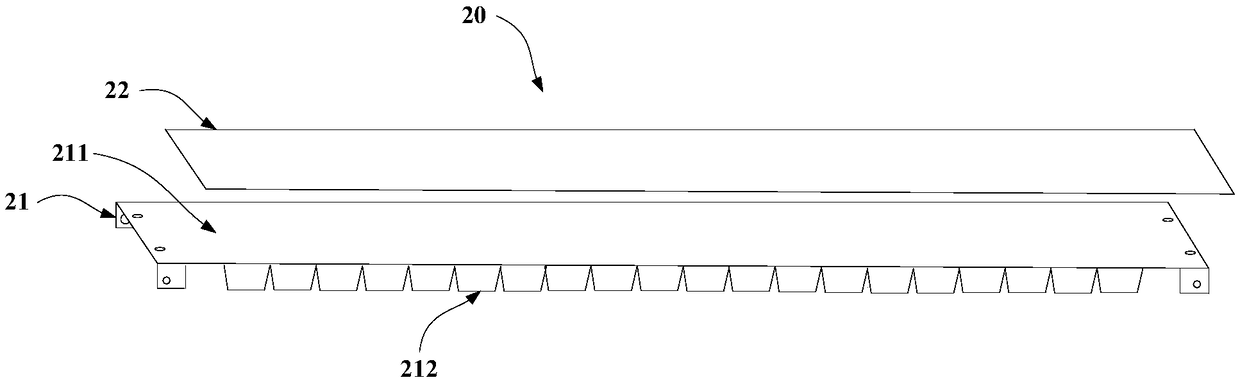

[0061] In order to solve the defect that the existing flexible screen terminal has no bending protection during the bending process and is prone to excessive bending damage, an embodiment of the present invention provides a terminal. Please refer to figure 2 , figure 2 It is a schematic structural diagram of a terminal provided by an embodiment of the present invention. The terminal 20 includes a bendable housing 21 and a flexible screen assembly 22 fixedly arranged on the upper surface 211 of the bendable housing 21 . Wherein, the flexible screen assembly 22 can be fixedly arranged on the upper surface 211 by bonding, for example, by bonding foam glue or other soft glue on the upper surface 211, so that the flexible housing 21 and the flexible screen assembly 22 can be Bend or flatten together.

[0062] The upper surface 211 of the flexible housing 21 can be an elastic metal sheet, such as an elastic steel sheet. The shape of the upper surface 211 can be rectangular, and t...

no. 2 example

[0087] An embodiment of the present invention provides a terminal assembly method for assembling the terminal described in the first embodiment above, please refer to Figure 18 , including the following steps:

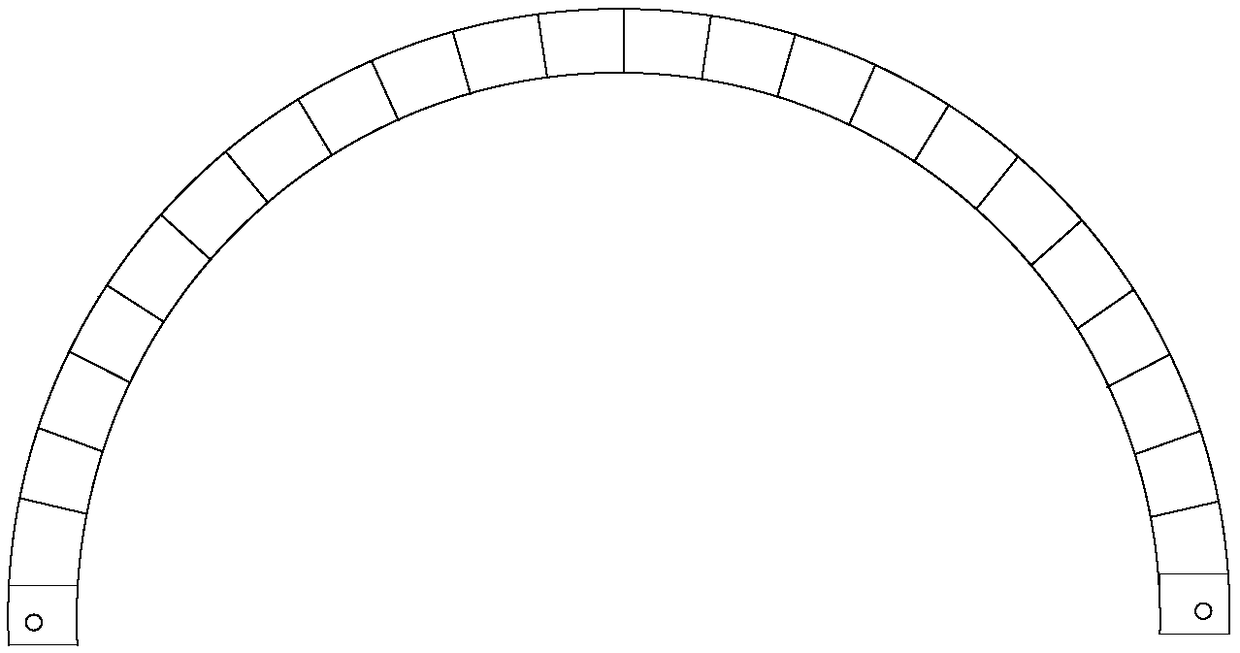

[0088] S181. The opposite sides of the bendable housing are symmetrically provided with sawtooth-shaped limiting structures, and the sawtooth-like limiting structures include a plurality of sawtooth blocks of the same shape and size, so that the opposite sides of the bendable housing are symmetrical The connection between the two sawtooth blocks is realized by welding a volume block, and an accommodating cavity is formed between the bendable shell and each volume block.

[0089] S182. Insert two dynamic steel sheets into the accommodation cavity, and connect the left end of one dynamic steel sheet to the bendable casing by screws, and connect the right end of the other dynamic steel sheet to the bendable casing by screws.

[0090] As for the end of the power steel sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com