Vortex plate type rotor filter

A vortex and filtration technology, which is applied in the field of vortex rotor filter, can solve the problems of non-continuous work, long intermittent cycle, incomplete separation, etc., and achieves simple structure, low equipment wear and power consumption, The effect of thorough solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

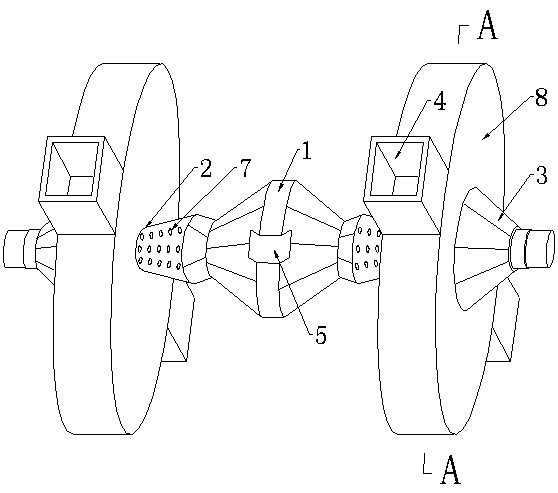

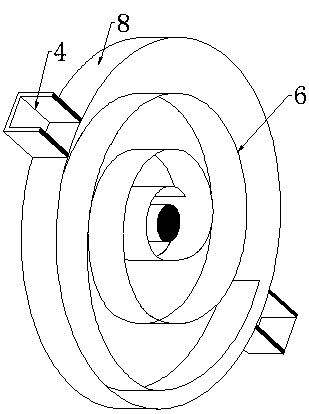

[0020] Such as figure 1 , figure 2 As shown, a vortex-type rotor filter filter includes a vortex 6, a power output device 3 is fixedly connected to the outer side of the vortex 6, and a casing of the sealed vortex 6 is installed on the outer side of the vortex 6 8. The inside of the scroll 6 is provided with a fixed bracket that communicates with the inside of the scroll 6 , the outside of the fixed bracket is provided with a pipe 2 , and the inner end of the pipe 2 is connected to the extrusion chamber 1 .

[0021] When the present invention is in use, the present invention utilizes the centrifugal force of the solid-liquid mixture during rotation to separate the water to achieve the purpose of fixed separation. Compared with the plate and frame filter press, the present invention does not need to use high-pressure gas for extrusion, and the equipment The wear and power consumption are relatively small. When in use, the power output device drives the scroll to rotate, and t...

Embodiment 2

[0023] Such as figure 1 , figure 2 As shown, a vortex-type rotor filter filter includes a vortex 6, a power output device 3 is fixedly connected to the outer side of the vortex 6, and a casing of the sealed vortex 6 is installed on the outer side of the vortex 6 8. The inner side of the scroll 6 is provided with a fixed bracket that communicates with the inside of the scroll 6, and the outer side of the fixed bracket is provided with a pipeline 2, and the inner end of the pipeline 2 is connected to the extrusion chamber 1, and the power output The power output center of the device 3 is collinear with the axis line of the housing 8, the fixed bracket is at the center of the housing 8, and one or more layers of filter screens are fitted on the fixed bracket, and the fixed bracket An adapted coaxial tube 2 is arranged on the periphery. One end of the tube 2 is in sealing connection with the shell 8, and the other end is in sealing connection with the extrusion chamber 1. The tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com