Vacuum air tank rail and chain type plug moving and adding mechanism

A technology of vacuum air and groove track, which is applied in the directions of sealing stopper, stopper feeding, stopper fixing, etc., can solve the problems of inability to distinguish medicine bottles, production line shutdown, rubber stopper falling, etc., to achieve stable and efficient operation, reliable performance, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

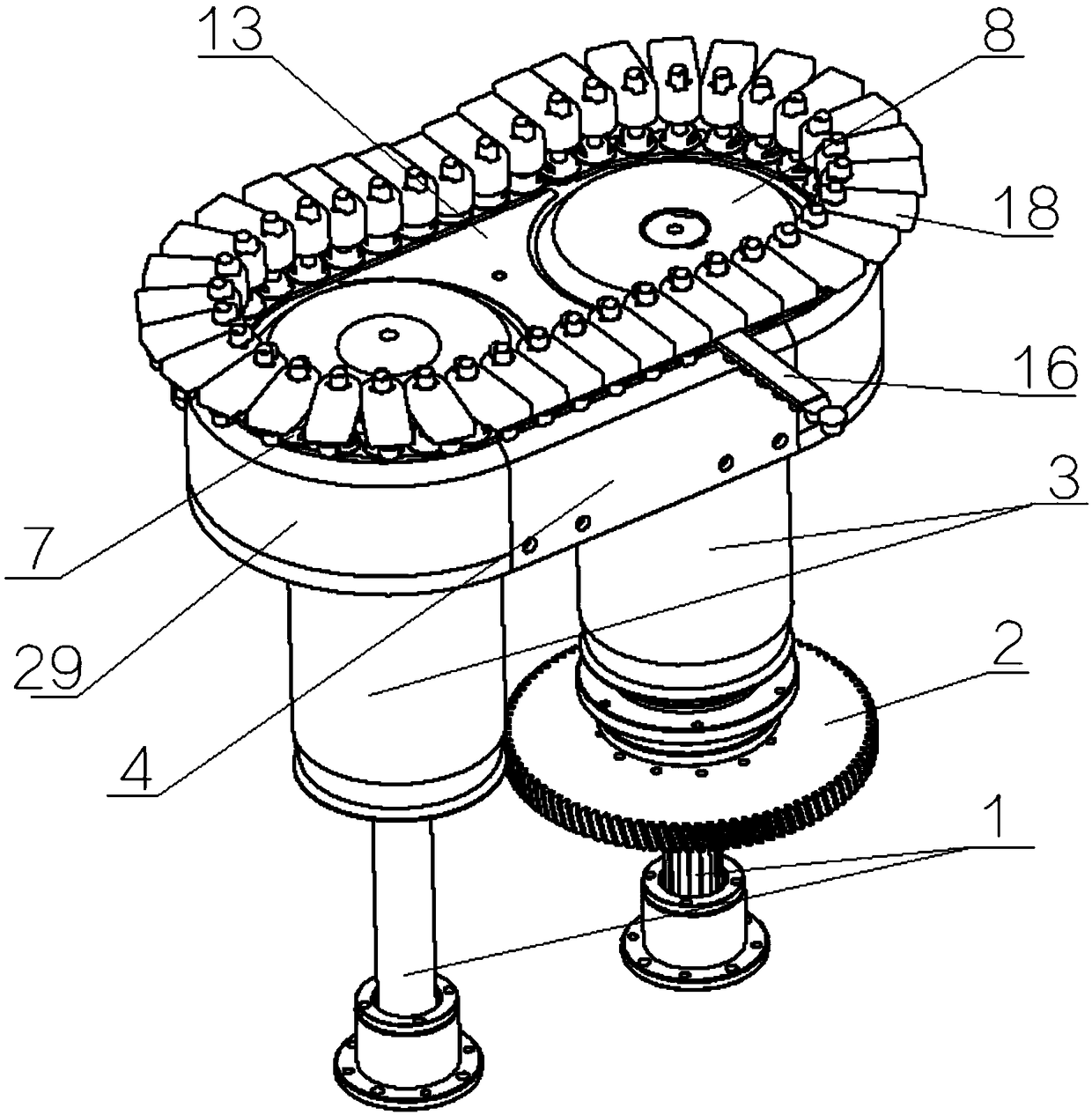

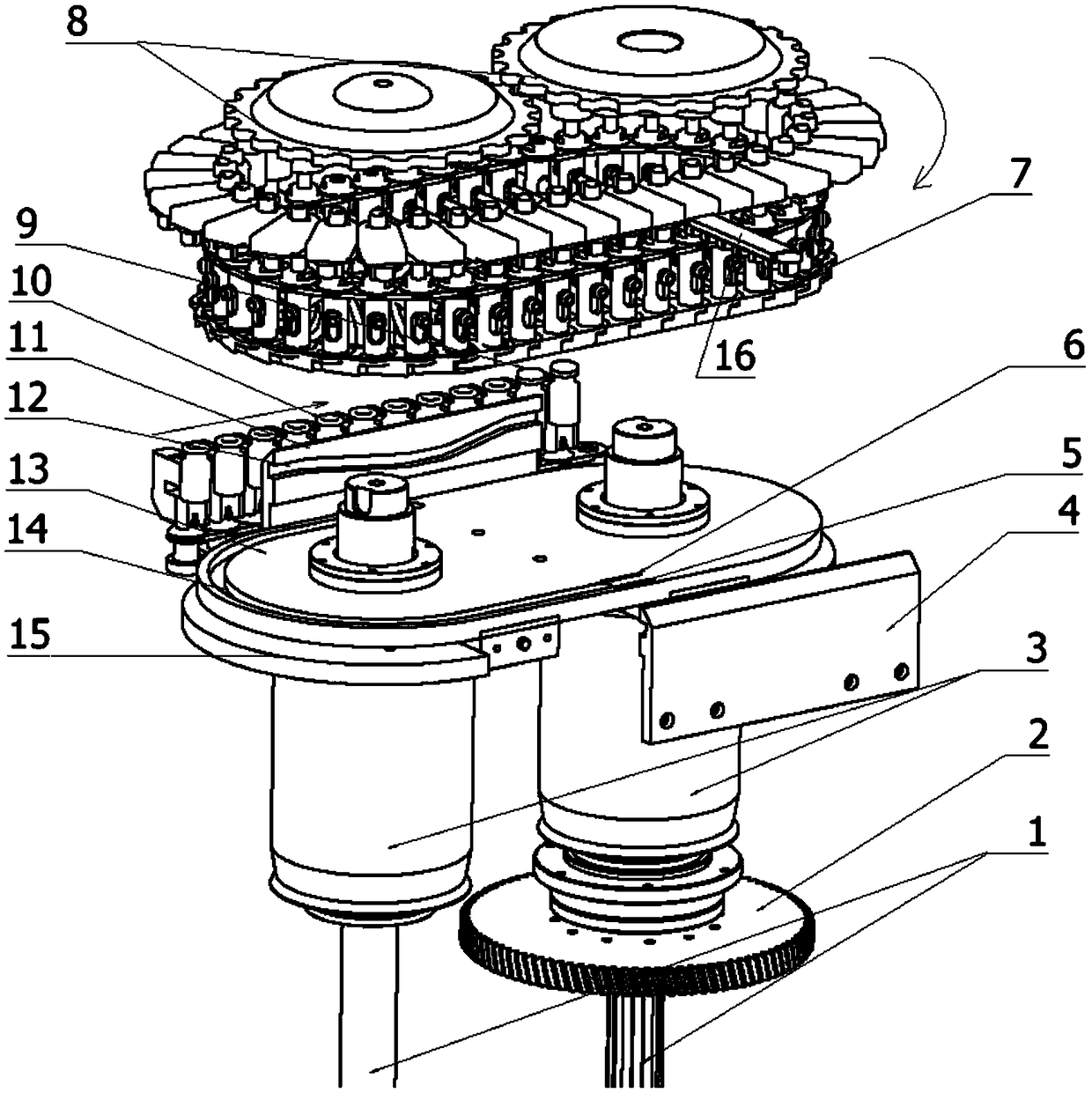

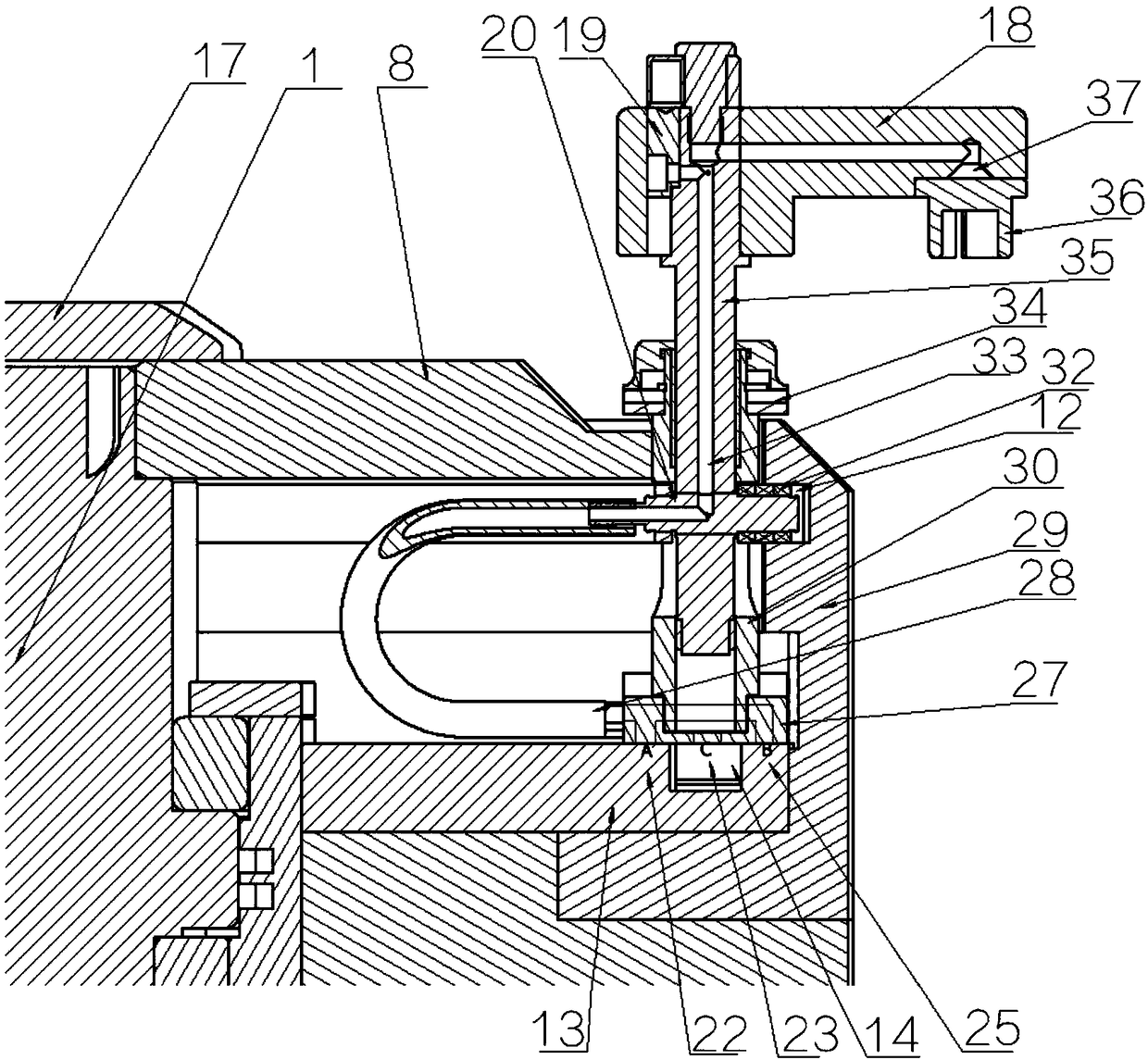

[0025] Such as Figure 1-8 As shown, it is a structural schematic diagram of a vacuum air groove track and a chain-type stoppering mechanism provided by the present invention, which includes a pair of central shafts 1, and each of the two central shafts 1 passes through the friction track disc 13 and the corresponding chain above it. The wheels 8 are connected, the central shaft 1 is connected and fixed with the friction track disc 13 through the bearing housing 3, and one of the central shafts 1 is connected with the driving gear 2 through the shaft, and the top of the sprocket 8 is provided with a sprocket pressing plate 17 for fixing the central shaft 1.

[0026] The outer sides of the two sprockets 8 are provided with endless chains 7 . Described endless chain 7 comprises a plurality of groups of friction plates 27 matched with the friction track disc 13 arranged along the conveying direction, each group of friction plates 27 comprises two friction plates 27, and each fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com