Clamping table for flattening tubular beam

A clamping table and flat technology, applied in the field of tooling and fixtures, can solve problems such as excessive manual participation, and achieve the effect of ensuring accurate injection, avoiding waste and ensuring firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

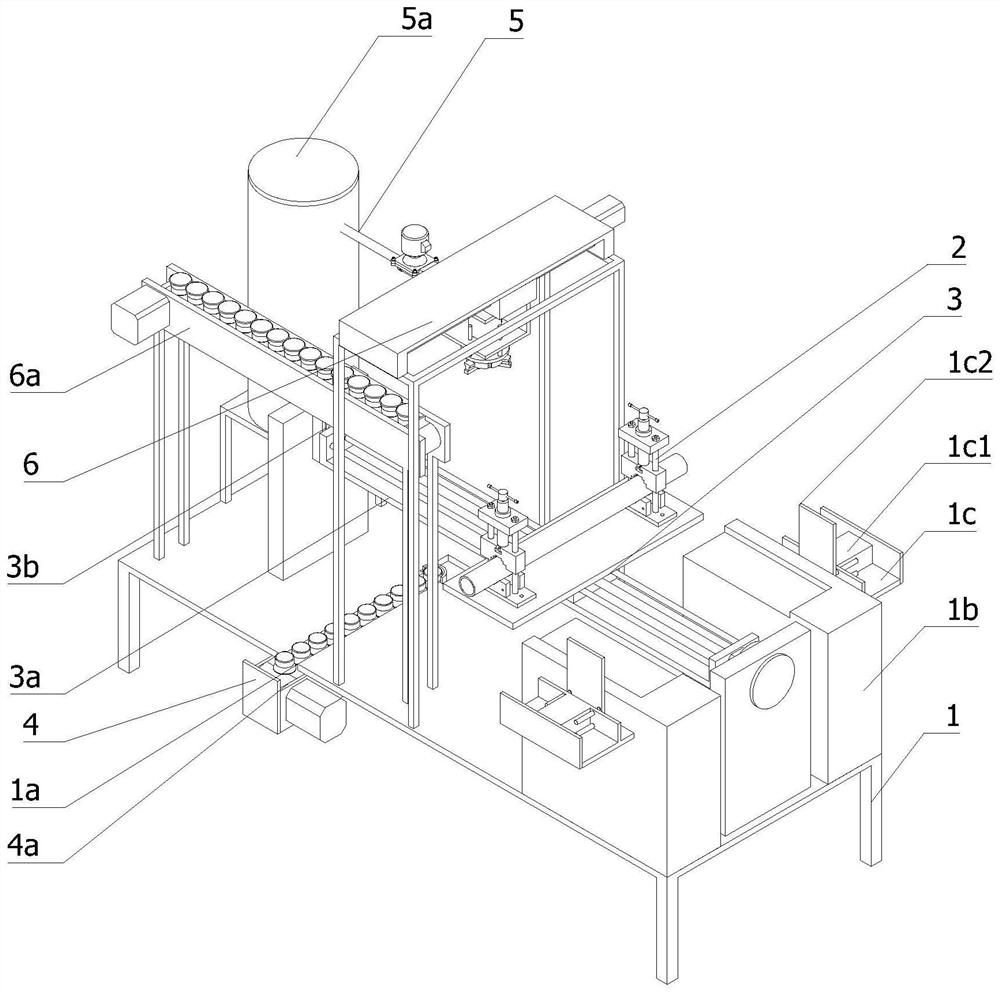

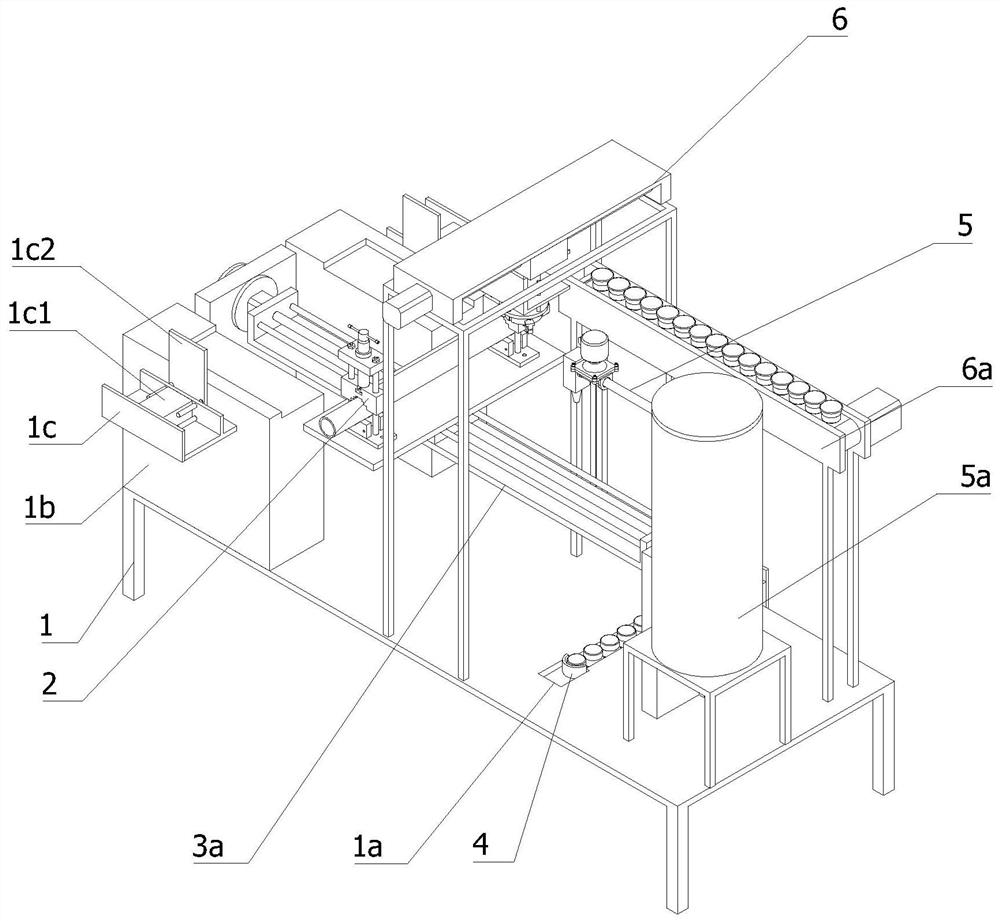

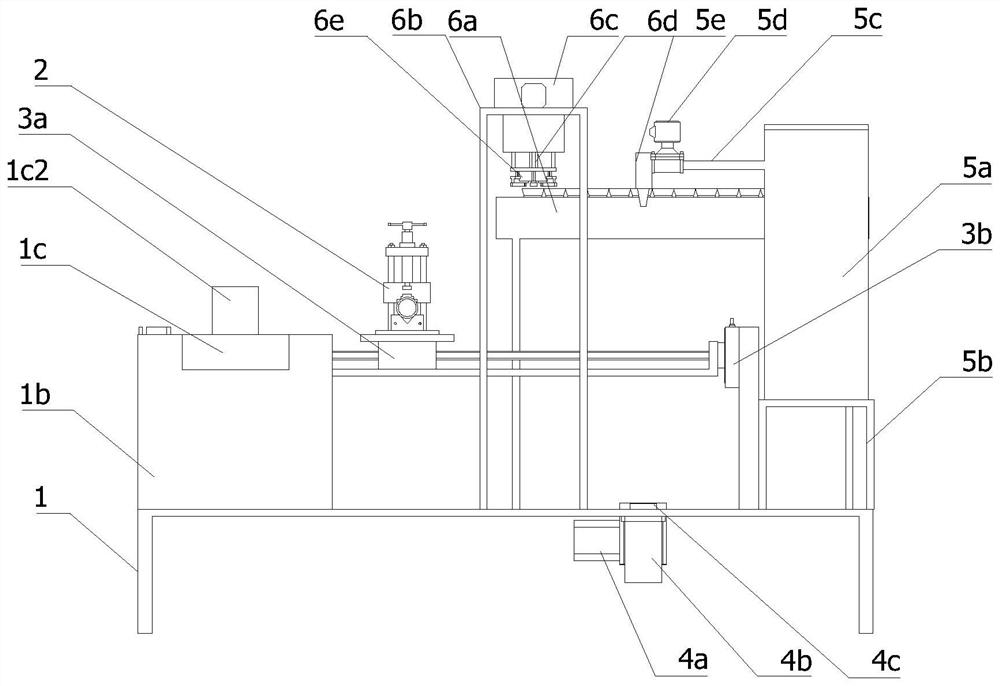

[0055] In order to realize the purpose of fixing steel pipes of different sizes, the two ends of the steel pipes are automatically plugged with wooden plugs, and an appropriate amount of water is automatically injected into the steel pipes, which solves the technical problems of excessive manual participation, such as figure 1 and 2 as shown,

[0056] A clamping platform for flattening a pipe beam, characterized in that it comprises,

[0057] Workbench 1, one side of the workbench 1 is provided with a first opening 1a, and the other side of the workbench 1 is provided with a flattening workbench 1b, which is the working area of the pipe beam flattening device, and the flattening work An encryption mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com