Energy-saving urban sewage treatment system

A technology for urban sewage and treatment systems, applied in biological water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. , increased pressure loss and other problems, to achieve the effect of strong dissolved oxygen capacity and strong aerobic decomposition capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

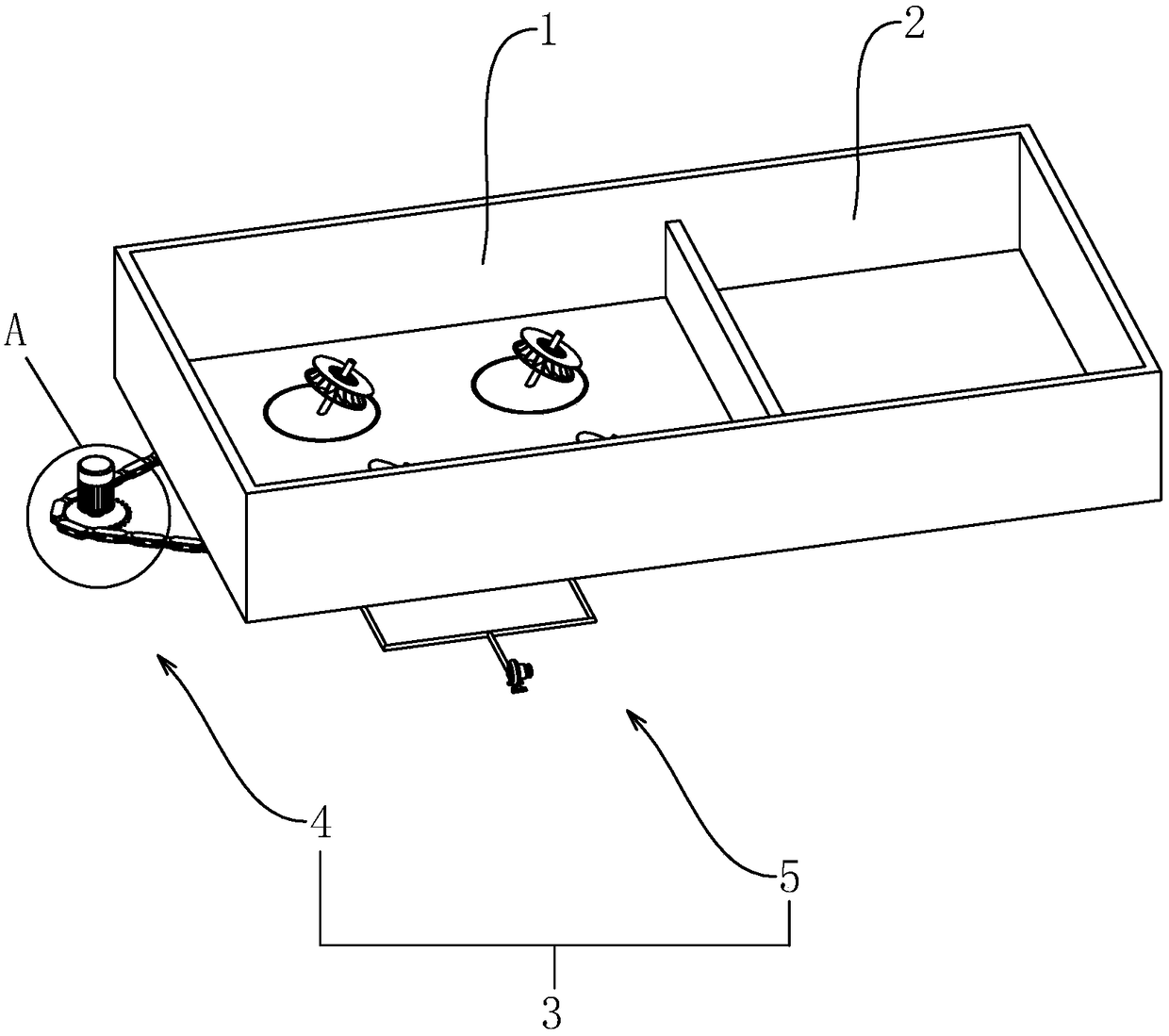

[0033] Such as figure 1 As shown, an energy-saving urban sewage treatment system includes an aeration tank 1 and a sedimentation tank 2. An aeration device 3 is installed in the aeration tank 1 to increase the amount of aeration and accelerate the process of aerobic decomposition. 1 After biodegradation, the impurities inside are precipitated through the sedimentation tank 2.

[0034] Such as figure 1 As shown, the aeration device 3 includes a stirring mechanism 4 for stirring the liquid in the aeration tank 1 and an air delivery mechanism 5 for transporting air into the aeration tank 1 .

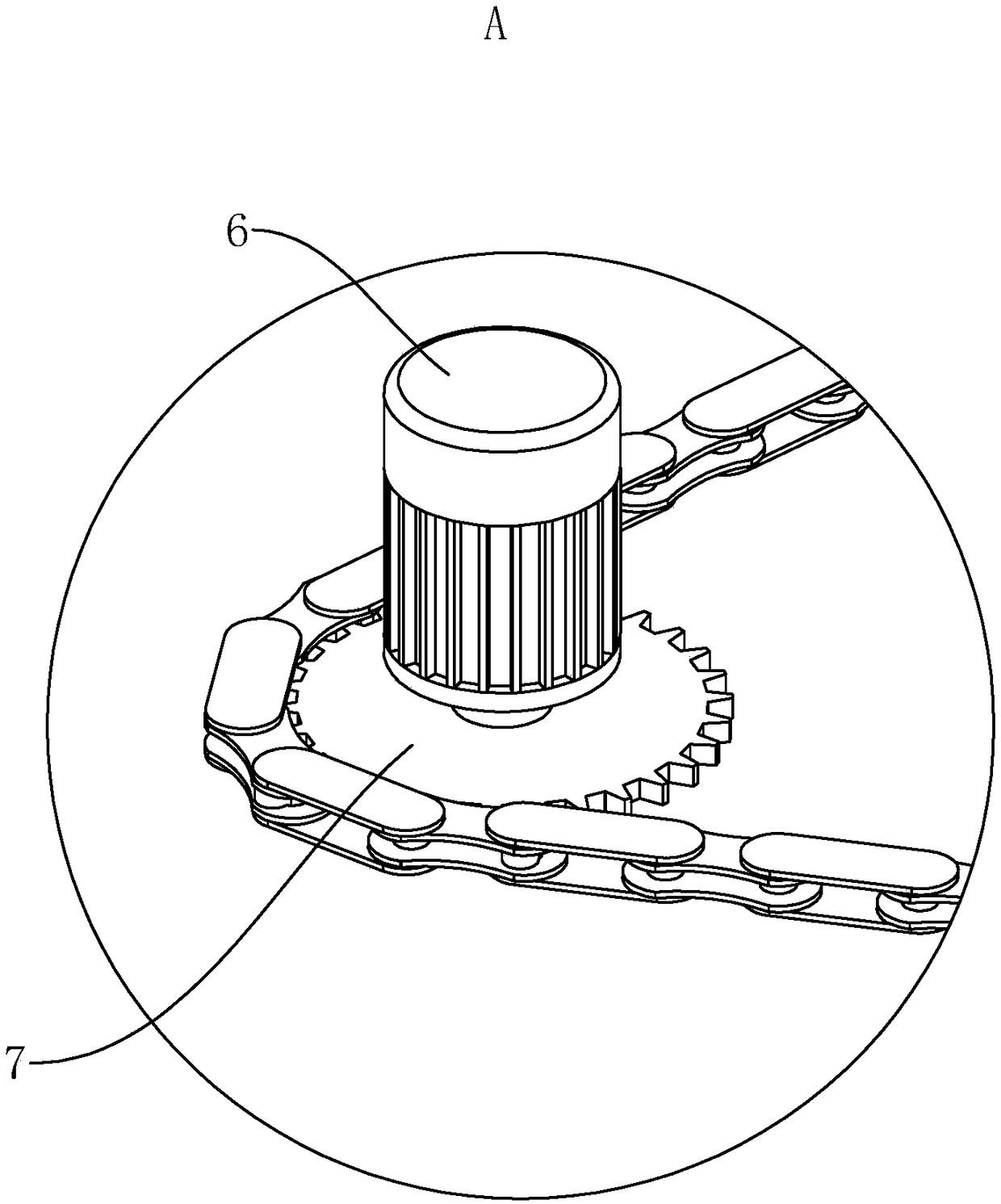

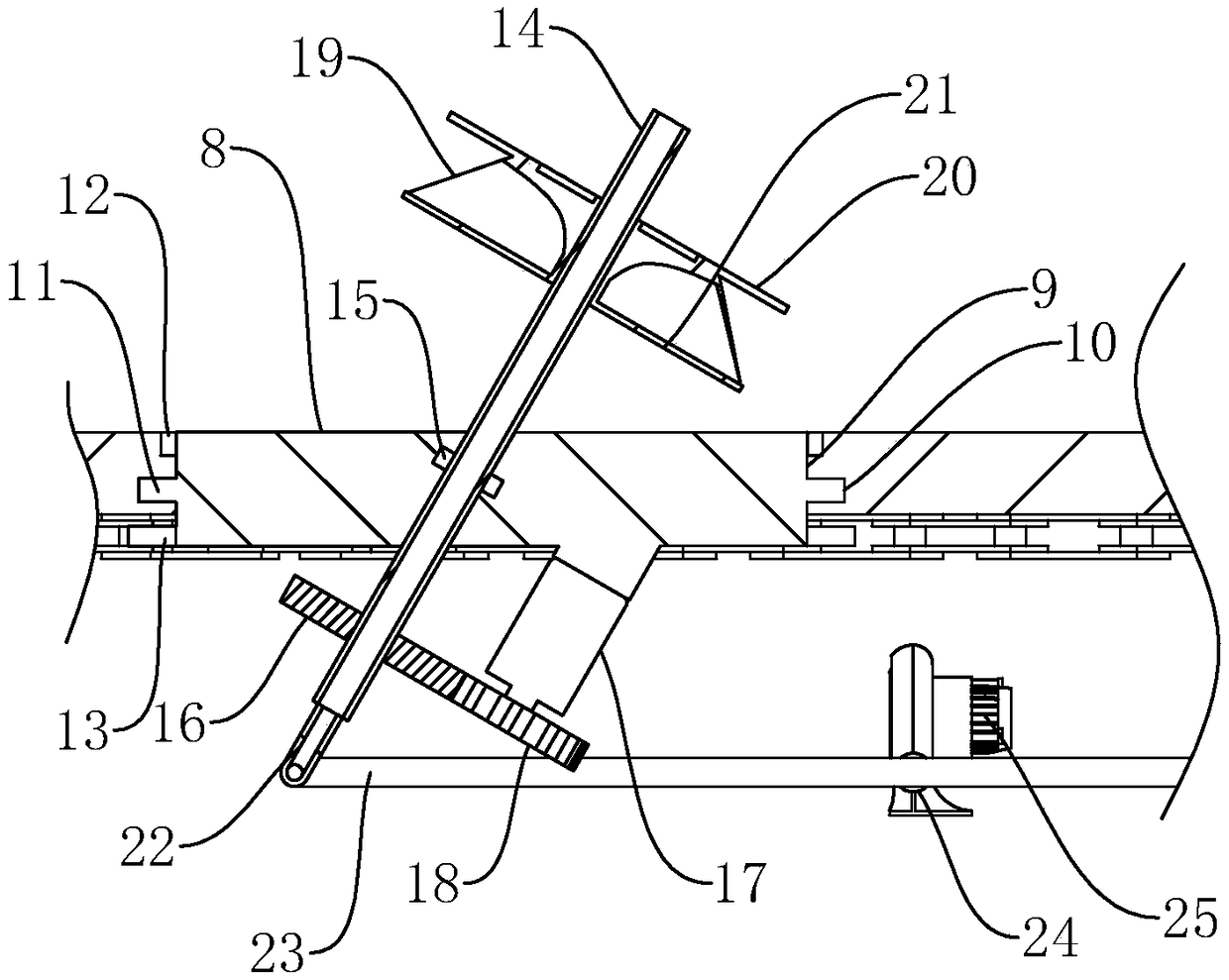

[0035] Such as figure 1 and figure 2 As shown, the stirring mechanism 4 includes a large motor 6, the direction of the output shaft of the large motor 6 faces the vertical direction and a driving sprocket 7 is installed on the output shaft thereof. The bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com