Overload clutch for speed reducer

An overload clutch and clutch technology, applied in the field of clutches, can solve the problems such as the safety of the binding device cannot be effectively guaranteed, the overload clutch slips, the system efficiency is reduced, etc., and achieves the effects of preventing slippage, improving life, and simple processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

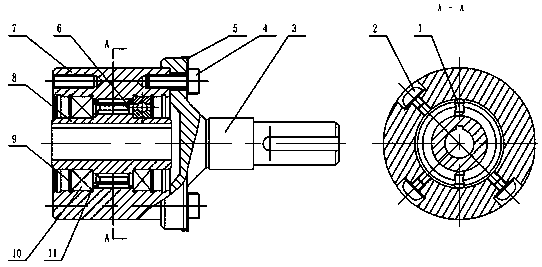

[0012] The present invention is further described below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, an overload clutch for a reducer includes a shaft 8, the shaft 8 penetrates the clutch housing 7, the sleeve shaft 3 is sleeved on the shaft 8, and withstands the clutch housing 7. The clutch housing 7 is divided into two parts and is fixed by screws 4. A plug 2 is installed on the casing 7, the inner cavity of the clutch casing 7 supports the shaft 8 through a bearing 10, a retaining ring 9 is arranged at the rear end of the bearing 10, a spacer 11 is arranged between the bearings 10, and a spacer 11 is arranged between the bearing 10 and the spacer 11. There is a stopper block 1, and a spring is installed on the stopper block 1.

[0014] A stop washer is provided between the screw 4 and the clutch housing 7 .

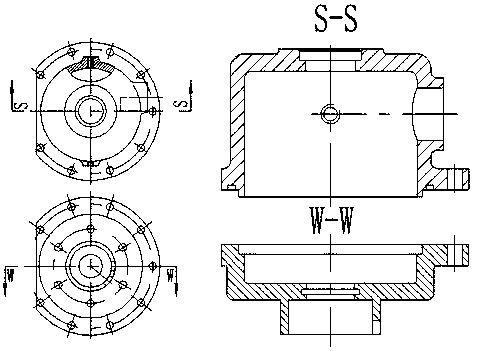

[0015] like figure 2 As shown, the clutch housing 7 may be provided with a protective cover.

[0016] The working principle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com