Efficient double-travel heat exchanger

A heat exchanger, double-pass technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of low heat exchange efficiency, easy scaling, heavy weight, etc., and achieve tube-side flow The effect of small resistance, high self-supporting strength, and easy construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

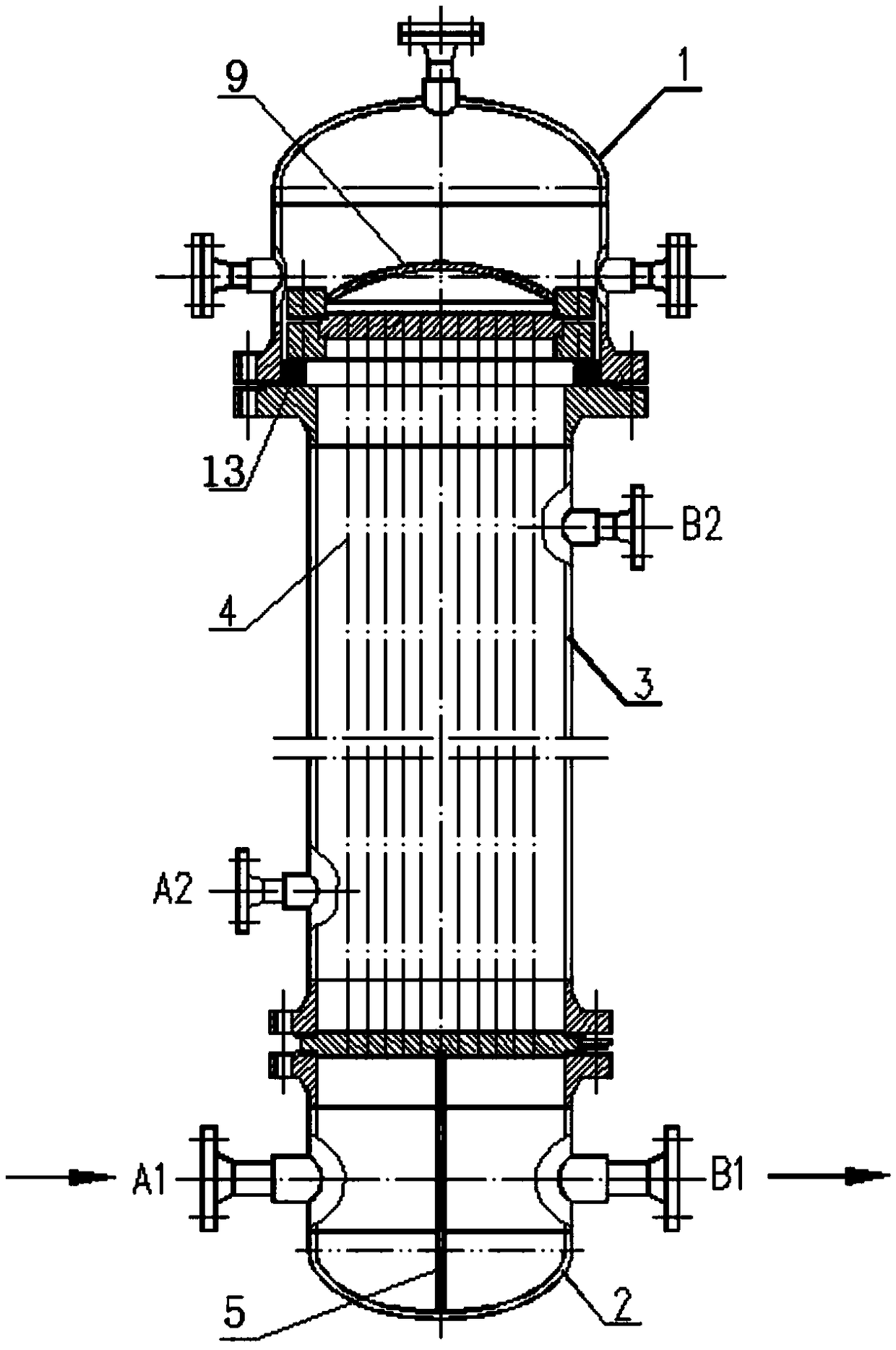

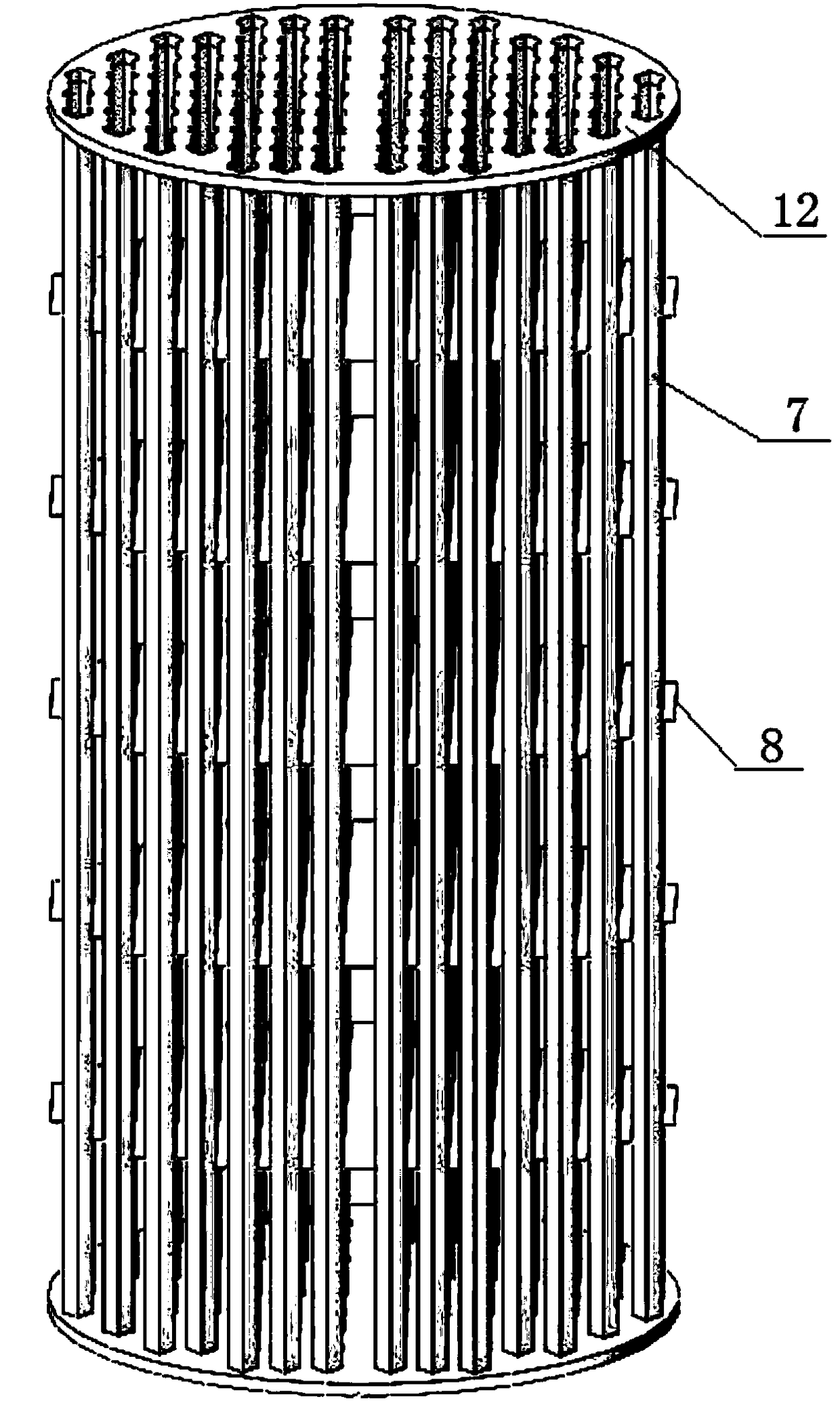

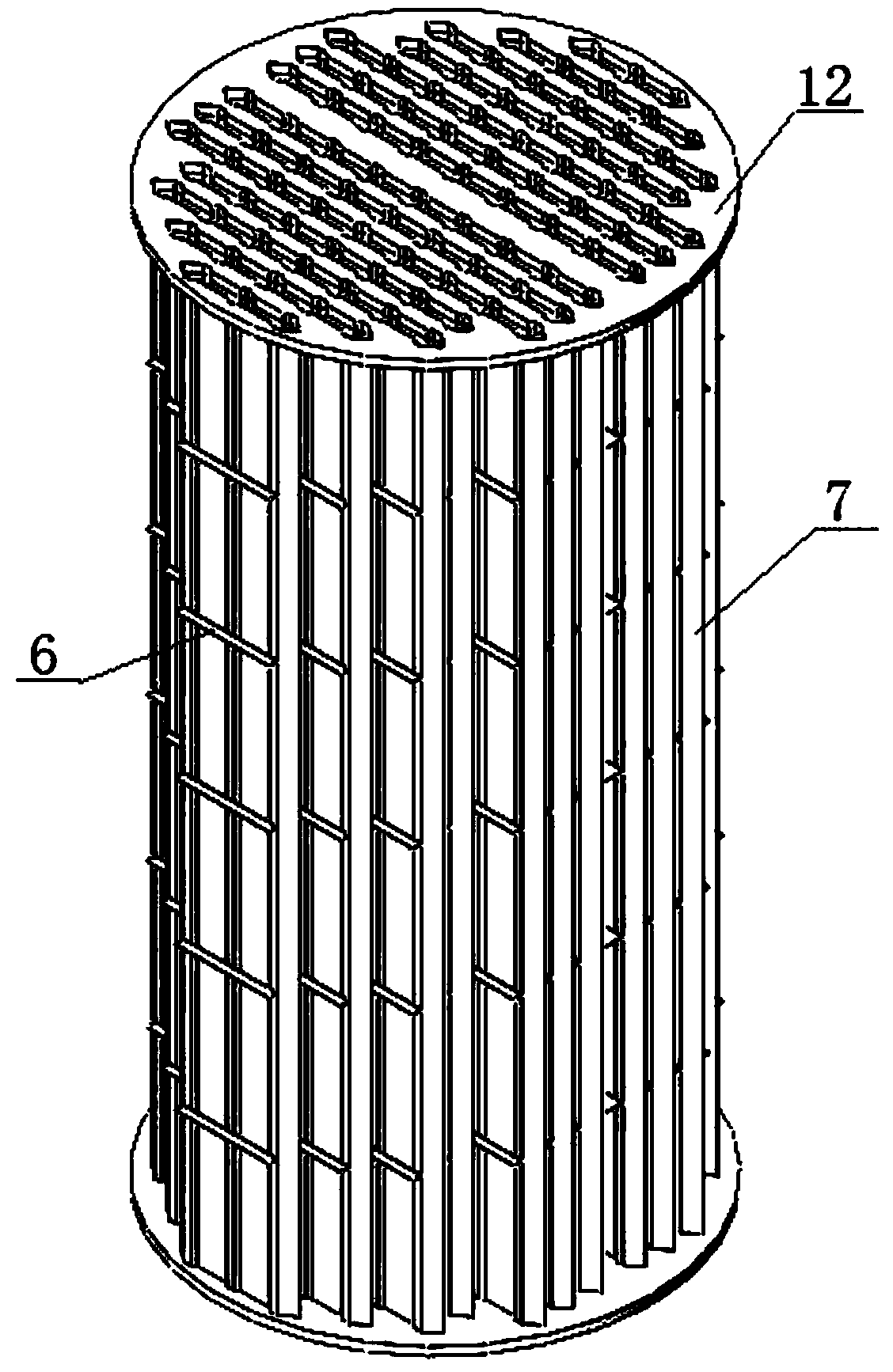

[0032] Such as figure 1 As shown, a high-efficiency double-pass heat exchanger according to the present invention includes a double-pass heat exchanger composed of an upper tube box 1, a lower tube box 2, a shell 3, and a heat exchange tube bundle 4. The lower tube box 2 is equipped with Partition partition 5; such as Figure 2-Figure 5 As shown, the heat exchange tube bundle 4 is composed of a plurality of tube plates 8 and multiple rows of flat heat exchange tubes 7 vertically arranged on the tube plates 8, and the cross section of the flat heat exchange tubes 7 has Concave-convex structures that are evenly spaced.

[0033] Such as Figure 4 As shown, the flat-mouth heat exchange tube 7 is made of a stainless steel plate after stamping, folding in half, and butt welding.

[0034] Such as Figure 5 As shown, the tube sheet 8 is a split struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com