Ultrasonic flow measuring method and low-power-consumption ultrasonic flow meter

A flow measurement and ultrasonic technology, applied in the field of flow detection, can solve the problems of low performance, low accuracy, limited application, etc., to achieve the effect of improving stability and accuracy, less external interference, and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

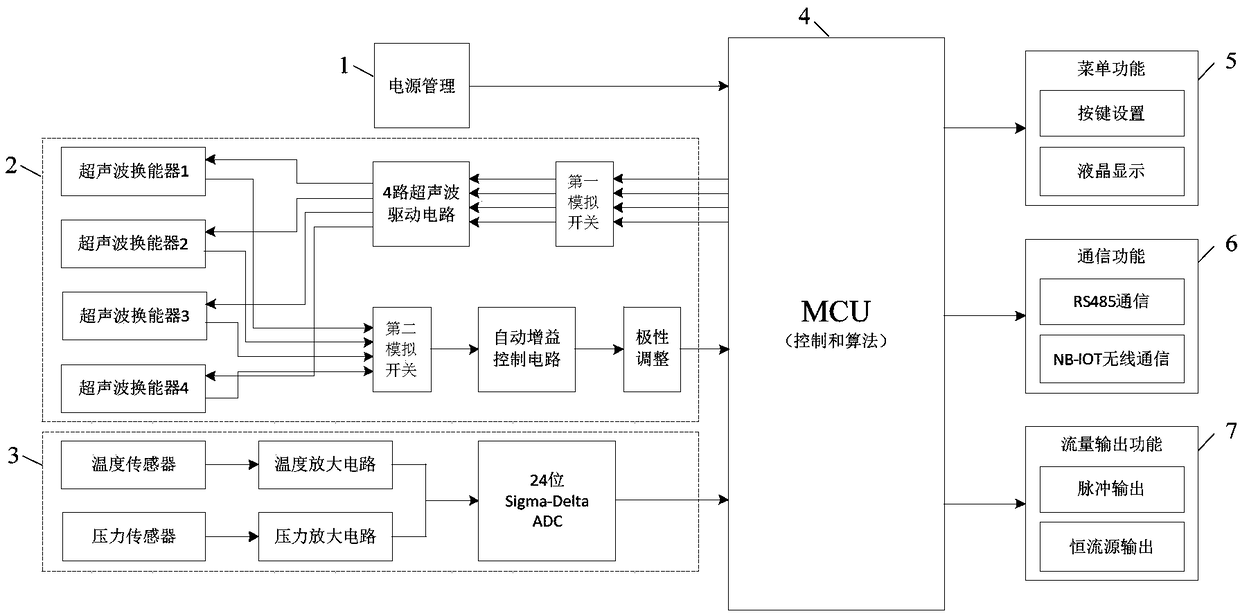

[0043] The present invention firstly proposes an ultrasonic flow measurement method: the method is to use the operation and processing capability of the MCU module to measure the flow with the ultrasonic signal as the object. , upstream time difference, and the absolute flight time in the downstream direction and upstream direction, in order to obtain three time parameters, the algorithm is specifically as follows: taking the downstream and upstream ultrasonic echo signals as input, using cross-correlation and three-parameter fitting sinusoidal curve algorithm , the output obtained by the calculation is the time difference of ultrasonic propagation in the downstream and upstream directions, taking the ultrasonic echo in the downstream direction and the static ultrasonic echo signal under zero flow as input, using the cross-correlation and three-parameter fitting sinusoidal algorithm, the calculation is The output is the absolute flight time in the downstream direction. The abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com