Antistatic material tray for electric energy meter

An electric energy meter, anti-static technology, applied in the direction of measuring electrical variables, instruments, measuring devices, etc., can solve problems such as shortening the normal service life, affecting product accuracy, and breakdown of electronic devices, so as to eliminate static electricity hazards and reduce frictional electrification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiment of this application discloses an anti-static material tray used for electric energy meters, which can reduce the frictional electrification of the tray, and at the same time add a metal sheet for releasing static charge on the tray, so that the static charge can be released through the ground wire in time , Effectively eliminate static electricity hazards.

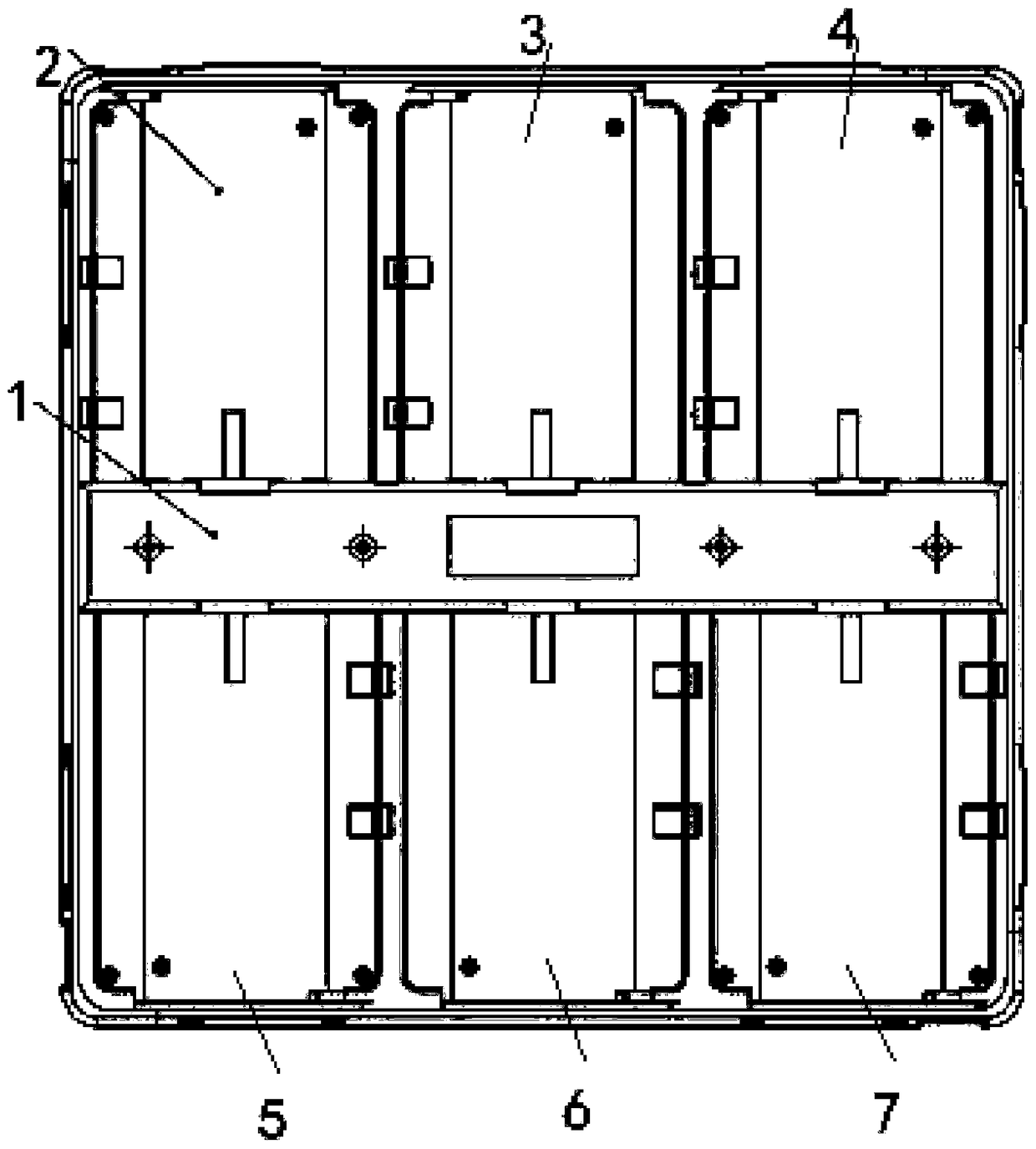

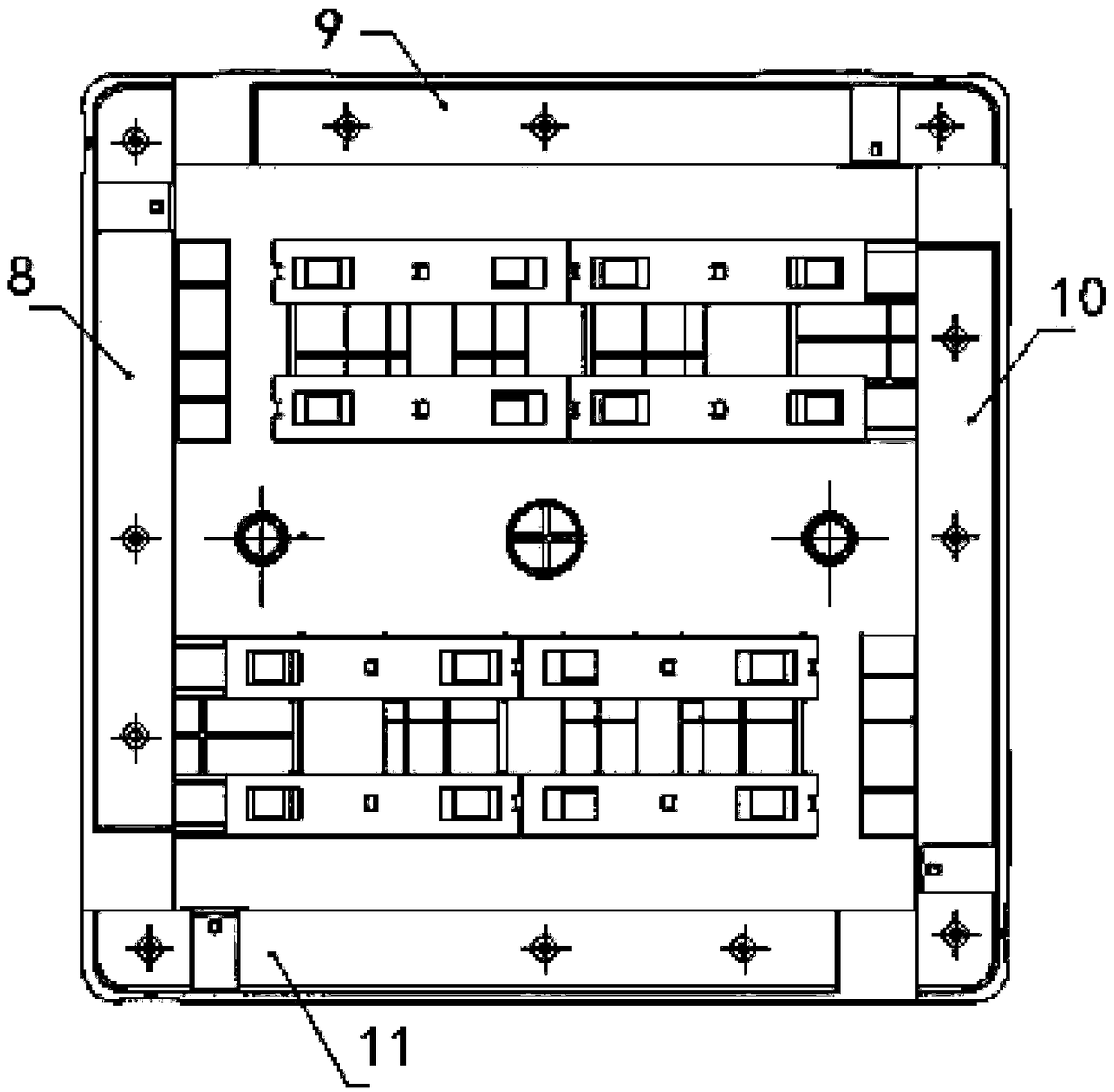

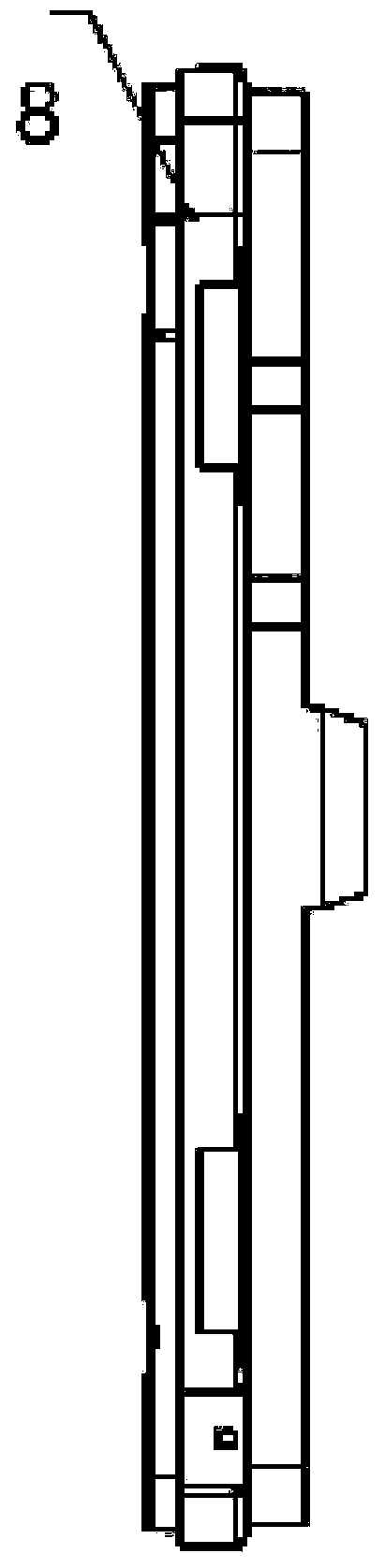

[0024] see Figure 1-5 , figure 1 A front view of an antistatic material tray for an electric energy meter provided in an embodiment of the present application; figure 2 A rear view of an antistatic material tray for an electric energy meter provided in an embodiment of the present application; image 3 A side view of an antistatic material tray for an electric energy meter provided in an embodiment of the present application; Figure 4 A structural schematic diagram of a tray bottom for an antistatic material tray for an electric energy meter provided in an embodiment of the present application; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com