Stirring device for mixing chemicals inside initiation tool

A technology for mixing medicines and stirring devices, which is applied in the directions of mixers, mixers, and mixer accessories with rotating stirring devices, can solve the problems of unsatisfactory stirring effect and poor safety, and achieves improved surface antistatic property and good discharge performance. , the effect of improving insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

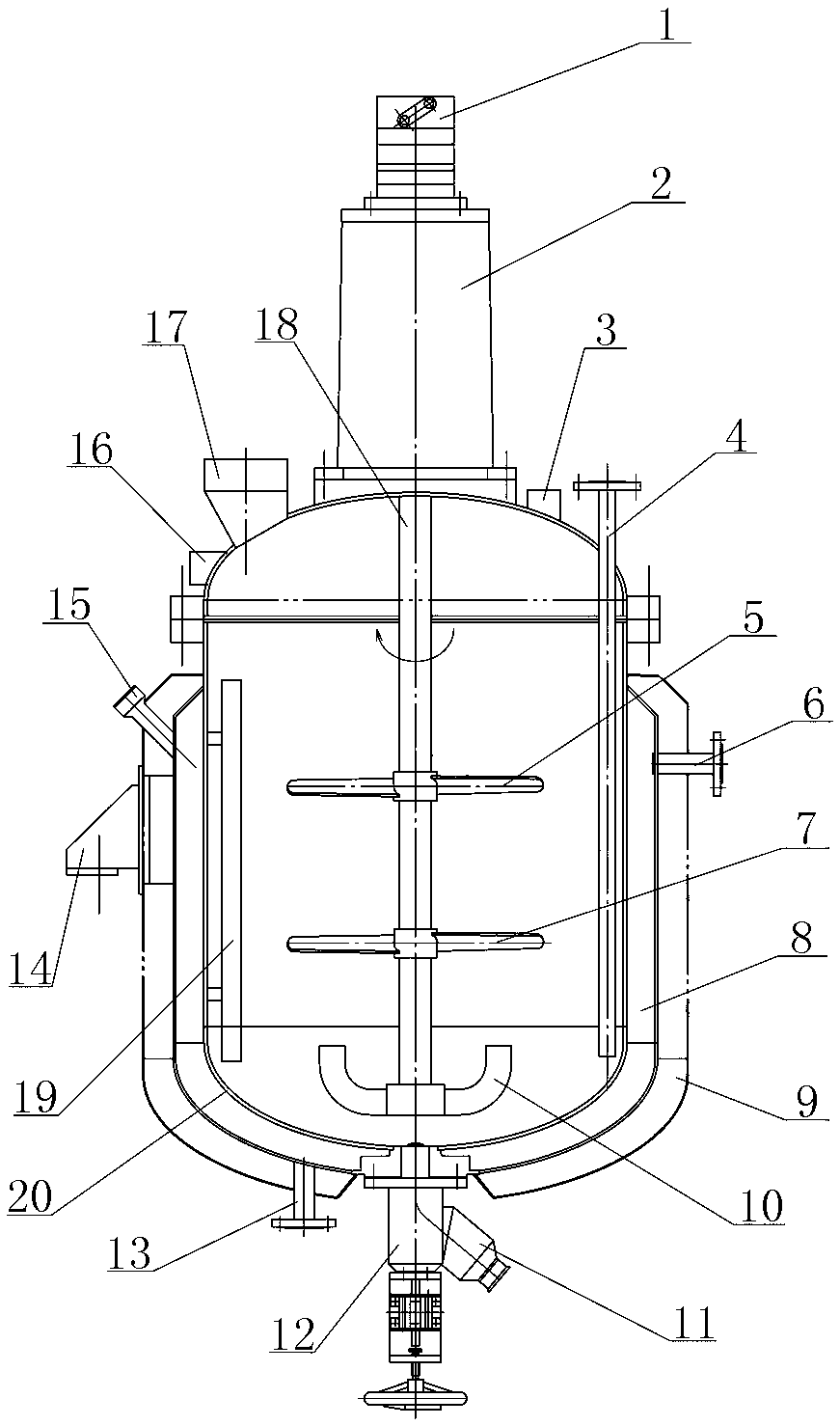

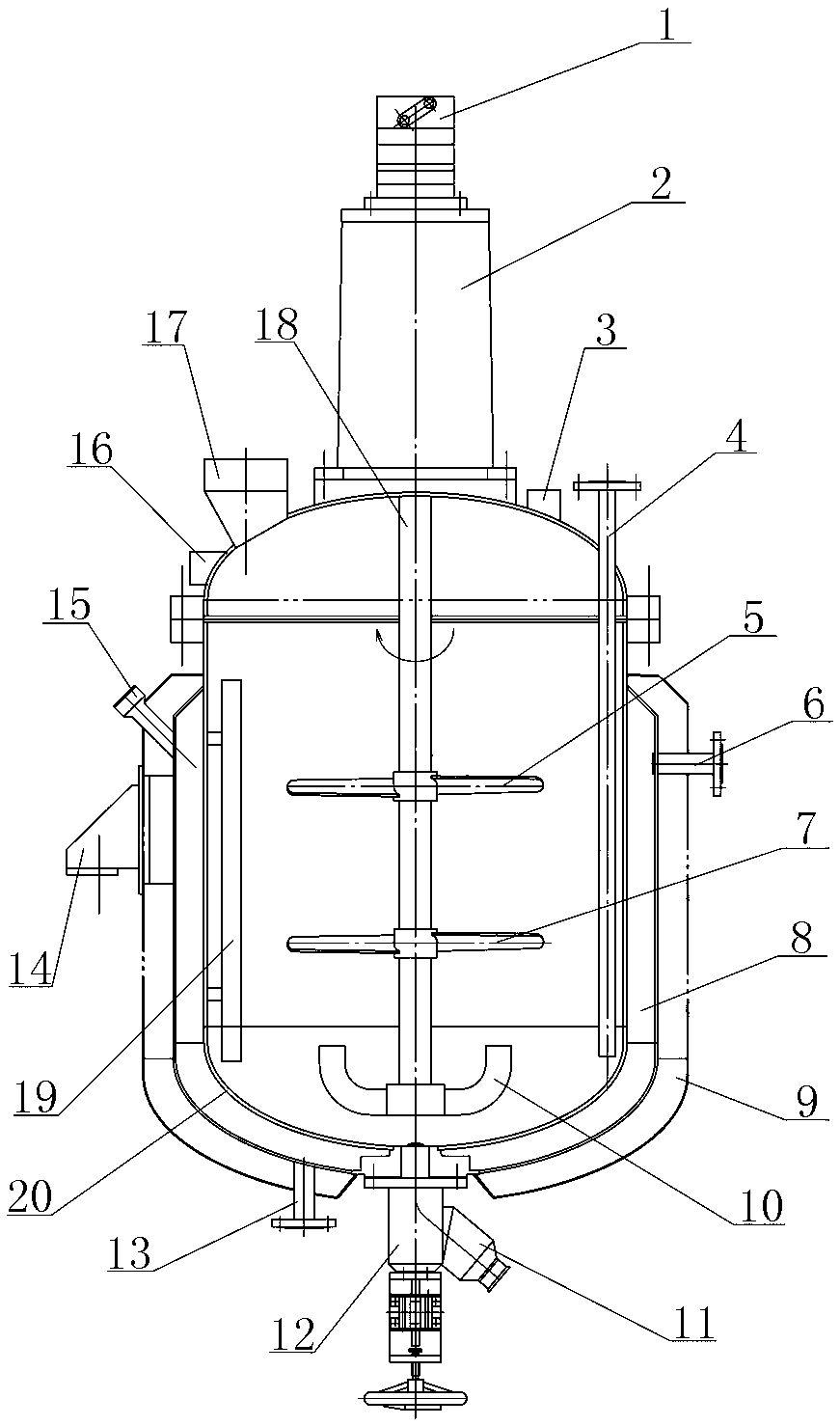

[0028] refer to figure 1 , the present invention includes a stirring tank body 20; the top and bottom ends of the stirring tank body 20 are circular arc structures of reverse outward expansion;

[0029] The top of the stirring tank 20 is provided with a hydraulic motor 1, and the hydraulic motor 1 is connected to the stirring shaft 18 in the stirring tank 20 through a reducer 2; The propeller blade 5, the reverse propeller blade 7 and the anchor paddle 10, and the forward propeller blade 5, the reverse propeller blade 7 and the anchor paddle 10 are respectively arranged in the upper, middle and lower parts of the stirring tank body 20;

[0030] The top of the stirring tank body 20 is respectively provided with a dust removal port 17, a liquid material feed port 16 and a powder material feed port 3 communicating with the inside thereof; the top of the stirring tank body 20 is provided with a thermometer installation pipe 4; The bottom of the thermometer mounting pipe 4 corresp...

Embodiment 2

[0037] As another embodiment of the present invention, the inner wall surface of the stirring tank is provided with an antistatic coating to avoid static electricity and friction ignition; the surfaces of the parts in contact with the mixed medicament are provided with an antistatic coating; the The antistatic coating is obtained by spraying the antistatic coating, and the thickness of the coating is controlled to be 0.5-1.0mm.

Embodiment 3

[0039] An antistatic coating, which is prepared according to the following process:

[0040]Dissolve acrylic resin and polyarylsulfone in dimethyl sulfoxide, stir at room temperature for 30 minutes, then add dimethyl silicone oil, and continue stirring for 15 minutes to obtain the main ingredient; acrylic resin, polyarylsulfone, dimethyl sulfoxide and dimethyl silicone oil The mass ratio is 2:1:10:3;

[0041] Mix nano-talc powder, nano-graphite and nano-boron carbide evenly to obtain a mixture, then add it to twice the weight of purified water, stir evenly, then add hexamethylcyclotrisiloxane, heat up to 60°C, ultrasonic (frequency 20KHz ) was dispersed for 5 minutes to obtain auxiliary materials; the mass ratio of nano-talc powder, nano-graphite, nano-boron carbide and hexamethylcyclotrisiloxane was 1:2:1:10;

[0042] Add the auxiliary materials to the main material at a mass ratio of 1:4, stir at a speed of 500rpm for 10 minutes, make it evenly mixed, and seal the package. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com