Protection device for current guiding conductor of super-high voltage and ultra-high voltage transmission line and installation method of protection device

A technology for transmission lines and protective devices, which is applied in cable installation, overhead installation, overhead line/cable equipment, etc. Good insulation effect and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings of the specification.

[0021] The specific voltage classification of UHV and UHV is:

[0022] 1. UHV transmission line voltage level: ①AC voltage 330kV-750kV; ②DC voltage: above ±400kV, below ±800kV.

[0023] 2. UHV transmission line voltage level: ①AC voltage 1000kV and above; ②DC voltage: ±800kV and above.

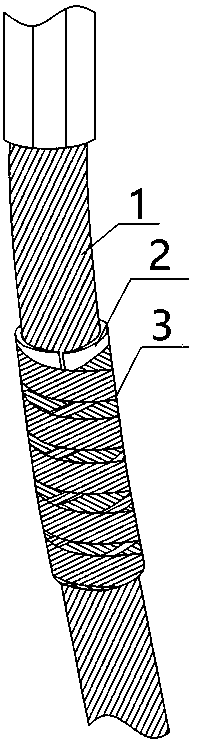

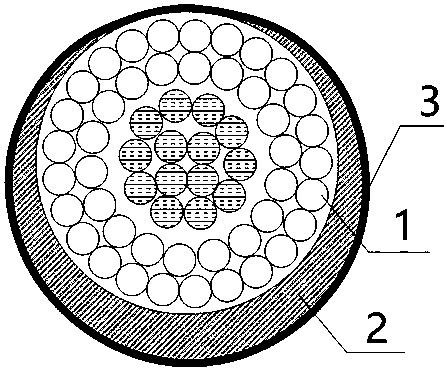

[0024] Such as Figure 1-2 As shown, an ultra-high-voltage and ultra-high voltage transmission line drainage conductor protection device includes a silicone rubber insulating sheath 2, a silicone rubber self-adhesive tape 3, and a steel cable tie arranged outside the conductor 1, and the silicone rubber self-adhesive tape 3 is wrapped around Outside the silicone rubber insulating sheath 2, a steel cable tie is tied tightly outside the silicone rubber self-adhesive tape 3.

[0025] In order to facilitate the sheathing on the wire 1, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com