A frame-type five-degree-of-freedom 3D printer

A technology of 3D printers and degrees of freedom, applied in the field of 3D printing, can solve problems such as inability to effectively cool down in time, high temperature of printing nozzles, high temperature corrosion of printing nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

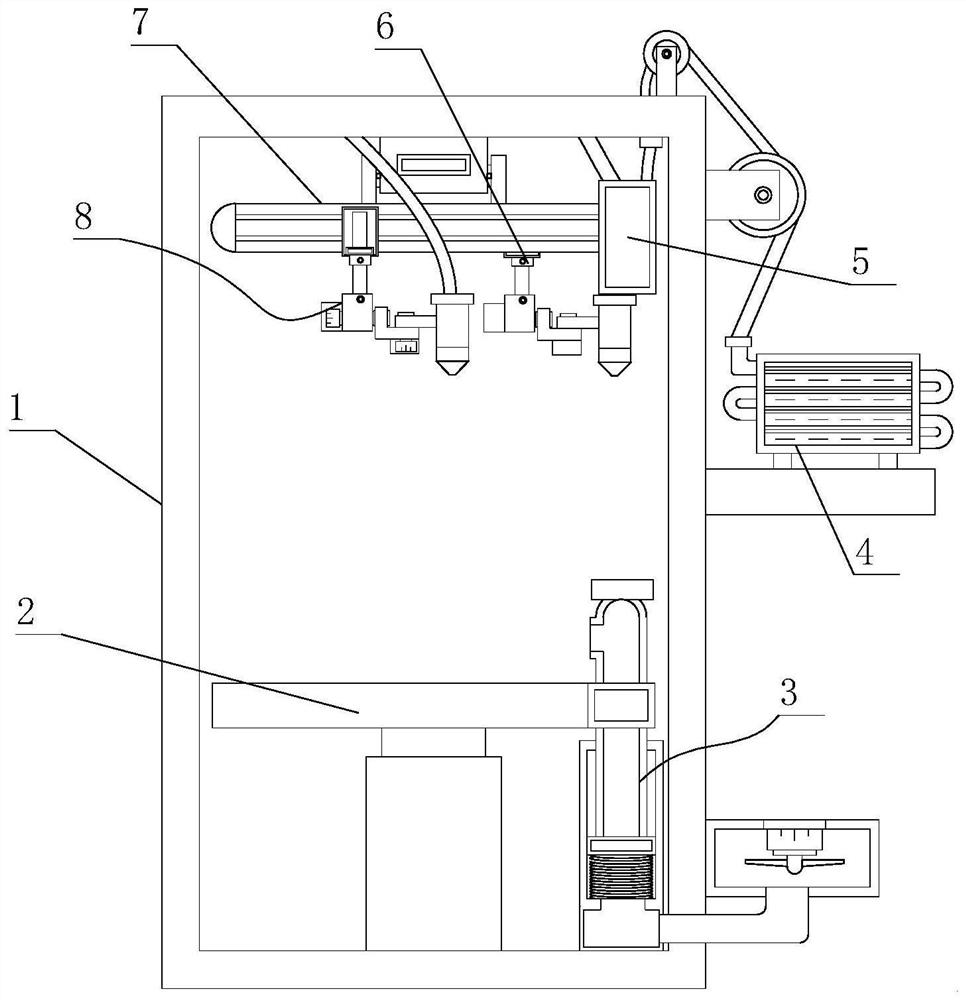

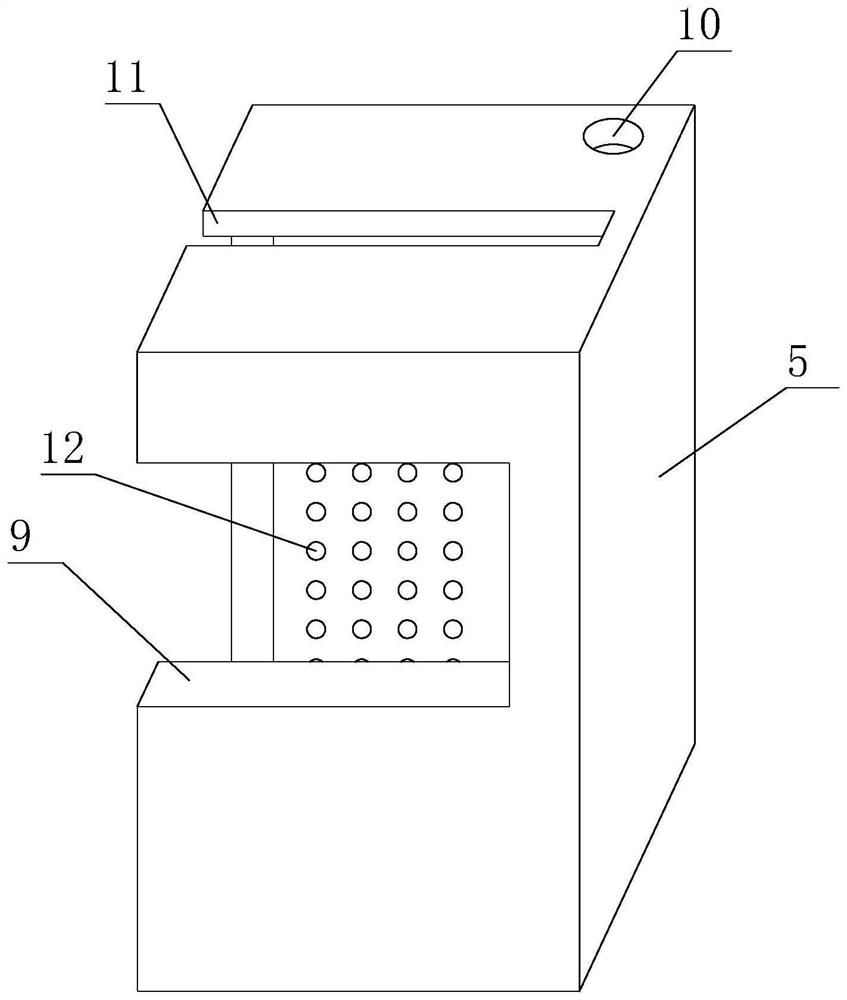

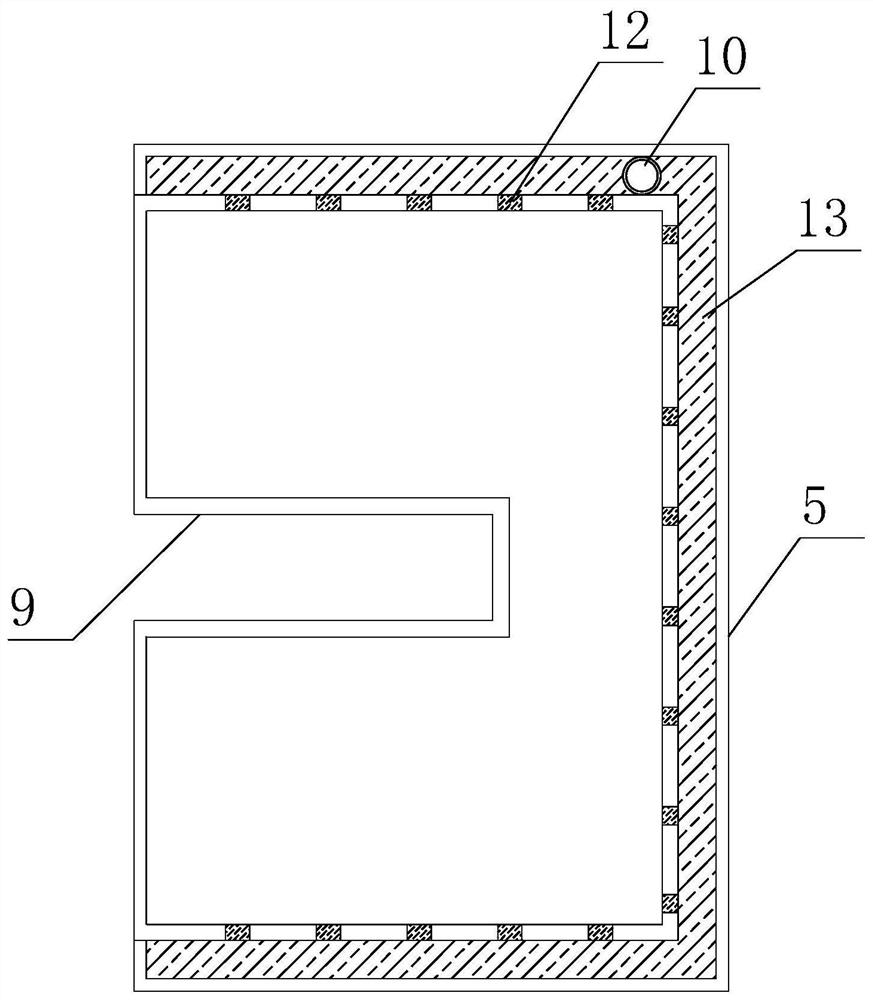

[0025]SeeFigure 1-7The present invention provides the following technical solutions: a frame type five-degree-of-freedom 3D printer, including a printer frame 1 and a sliding arm 7 connected by a slider at the top of the printer frame 1, and one side of the sliding arm 7 is connected by a slider In the printing nozzle 6, the two sides of the sliding arm 7 are connected with a cooling box 5 by bolts. The top side of the two cooling boxes 5 is provided with a pipe groove 11, and the two cooling boxes 5 are provided with a slider groove 9 on one side. , The upper surface corners of the two cooling boxes 5 are provided with cold air inlets 10, the inner surfaces of the two cooling boxes 5 are provided with cold air grooves 13, and the inner surfaces of the two cooling boxes 5 are provided with a number of cold air outlets 12, The internal bottom end of the printer frame 1 is connected to the printing object placement plate 2 through a lifting rod. The air condenser 4 sucks and cools the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com