Logistics frame for logistics box transportation

A logistics box and logistics technology, which is applied in the field of logistics racks, can solve the problems of not being able to meet the needs of use, and can not adjust the transportation width, so as to achieve the effect of stable cargo transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

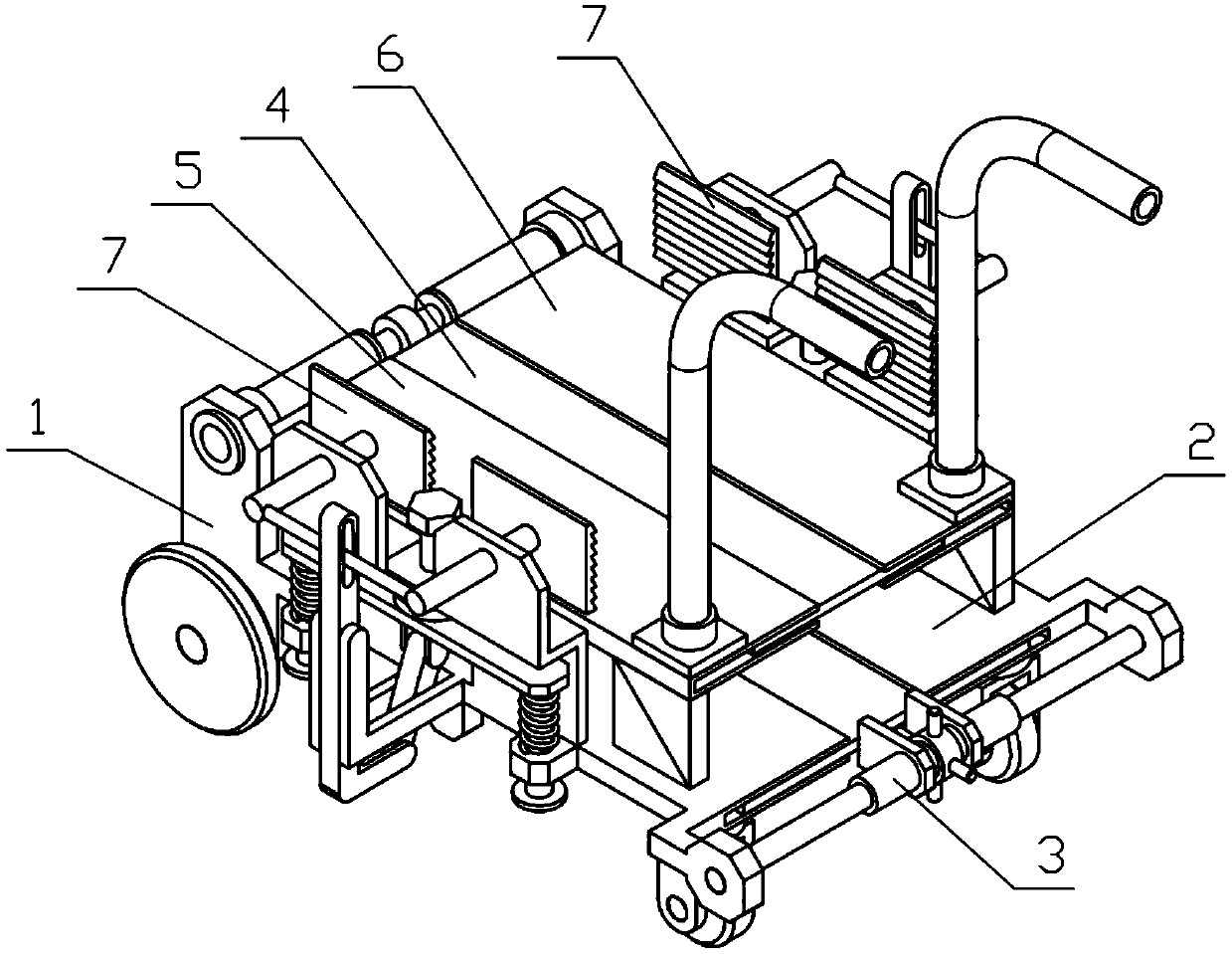

[0033] Combine below Figure 1-12 Describe this embodiment, a logistics box transport logistics rack, including side bracket I1, side bracket II2, sliding bracket 3, support bracket 4, transport bracket I5, transport bracket II6 and clamping mechanism 7, which can be installed on the sliding bracket 3 by rotating The sliding and turning handle 3-4 of the two sliding threaded rods 3-5 rotates in the opposite direction, pushing the side bracket I1 and the side bracket II2 on the sliding bracket 3 to perform the relative sliding between the side bracket I1 and the side bracket II2 The distance is changed, the side bracket I1 and the side bracket II2 respectively drive the transportation bracket I5 and the transportation bracket II6 to slide on the support bracket 4, and the relative distance between the transportation bracket I5 and the transportation bracket II6 is changed to change the width of the device, so that The device can be applied to goods of different widths and diffe...

specific Embodiment approach 2

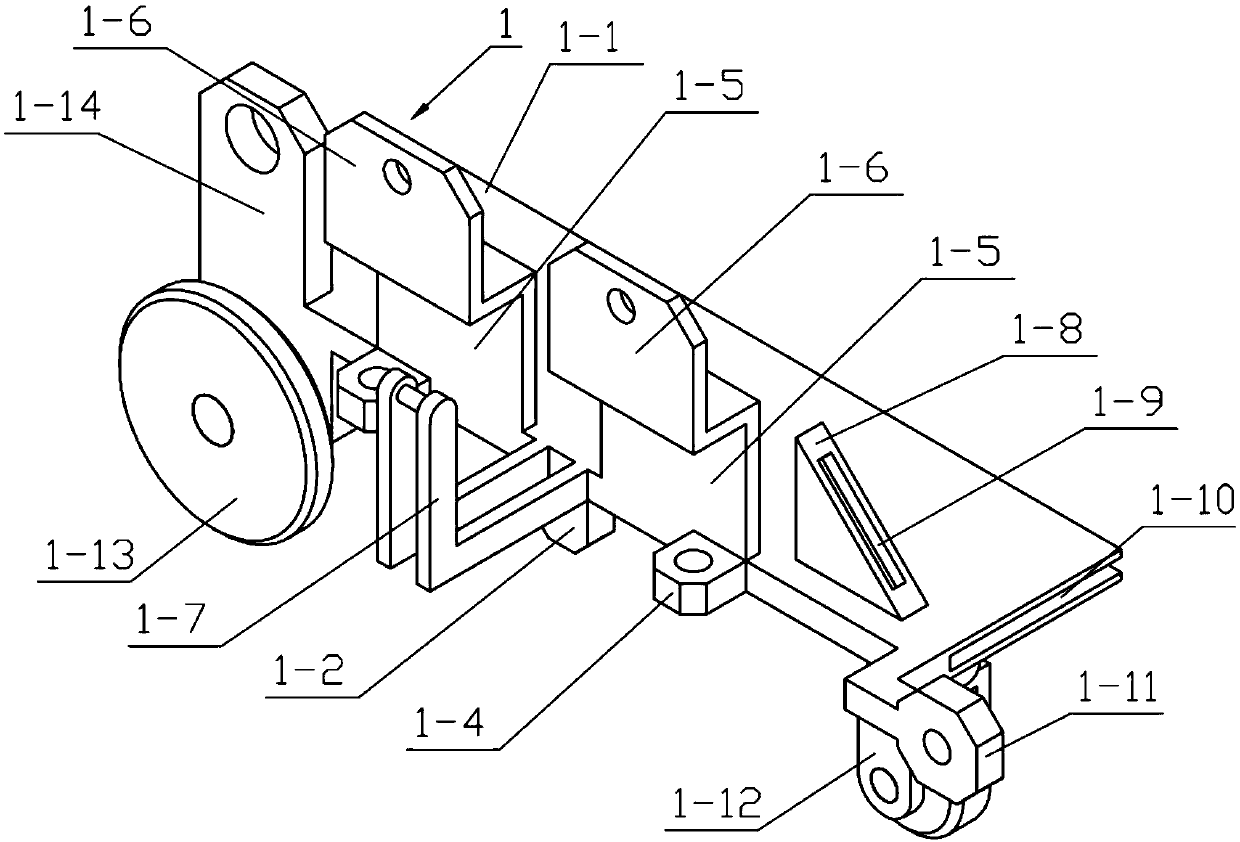

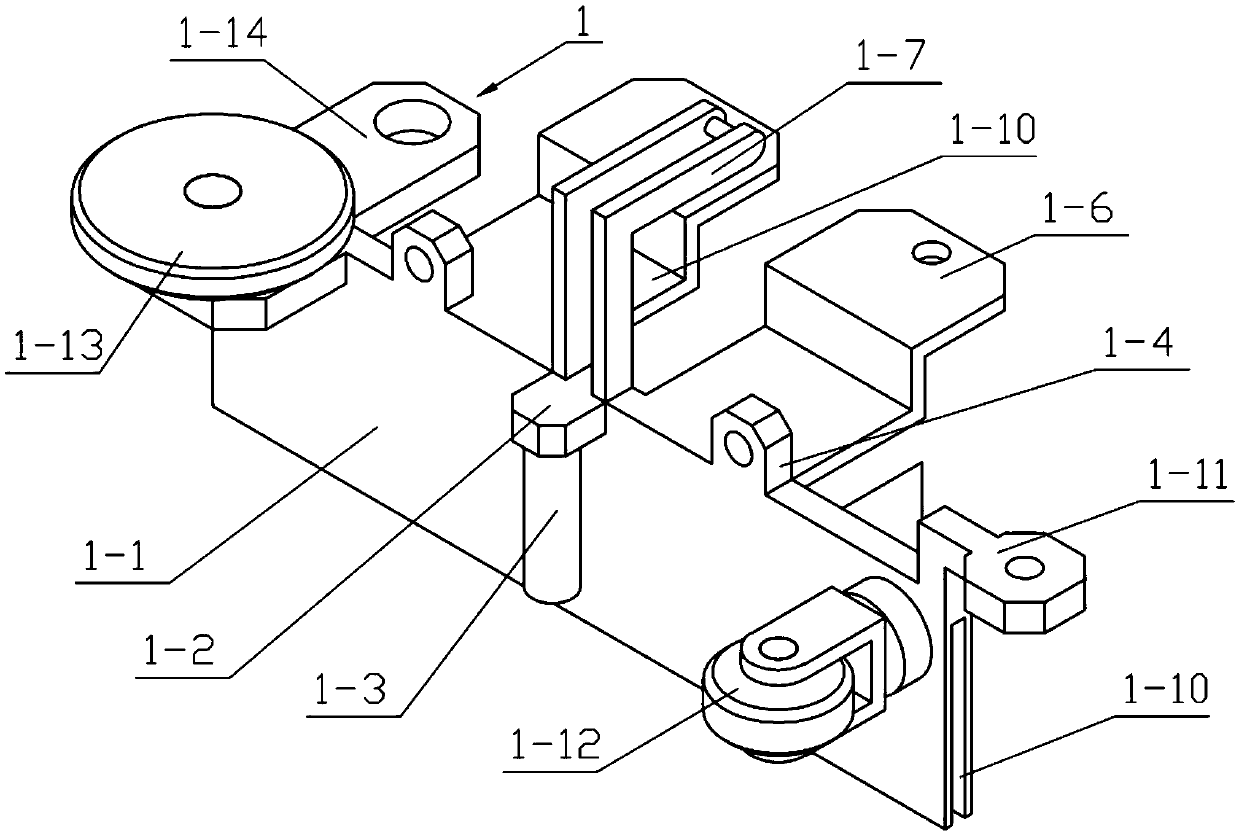

[0034] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the first embodiment, the side bracket I1 includes the bottom plate I1-1, the lower connecting plate I1-2, the sliding cylinder I1-3, the sliding support plate I1-4, the support plate I1- 5. L-shaped support plate Ⅰ1-6, L-shaped connecting rod bracket Ⅰ1-7, triangular plate Ⅰ1-8, interference groove Ⅰ1-9, sliding groove Ⅰ1-10, rotating support plate Ⅰ1-11, universal wheel Ⅰ1- 12. The walking wheel I1-13 and the hinged support plate I1-14, the middle end of the lower side of the bottom plate I1-1 is fixedly connected with the lower connecting plate I1-2, and the lower connecting plate I1-2 is fixedly connected with the sliding cylinder I1-3, One side of the bottom plate I1-1 is fixedly connected with two sliding support plates I1-4, the other side of the bottom plate I1-1 is provided with a sliding groove I1-10, and one side of the upper end of the bottom plate I1-1 is fixedly conne...

specific Embodiment approach 3

[0035] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the side bracket II2 includes a bottom plate II2-1, a lower connecting plate II2-2, a sliding cylinder II2-3, a sliding support plate II2-4, and a support plate II2 -5, L-shaped support plate Ⅱ2-6, L-shaped connecting rod bracket Ⅱ2-7, triangular plate Ⅱ2-8, interference groove Ⅱ2-9, sliding groove Ⅱ2-10, rotating support plate Ⅱ2-11, universal wheel Ⅱ2 -12. Walking wheels Ⅱ2-13 and hinged support plate Ⅱ2-14, the middle end of the lower side of the bottom plate Ⅱ2-1 is fixedly connected with the lower connecting plate Ⅱ2-2, and the lower connecting plate Ⅱ2-2 is fixedly connected with the sliding cylinder Ⅱ2-3 , one side of the bottom plate Ⅱ2-1 is fixedly connected with two sliding support plates Ⅱ2-4, the other side of the bottom plate Ⅱ2-1 is provided with a sliding groove Ⅱ2-10, and one side of the upper end of the bottom plate Ⅱ2-1 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com